Myth or Reality?

Each group needs:

- 1 empty 2 L bottle; clear plastic soda bottles work best so students can observe quicksand in action

- 1 m flexible tubing or a 1 m section of old garden hose; fittings removed or cut off

- small round objects of similar sizes but different densities; for example, a metal ball, large marble, and a lime:

- Note: one object needs to be denser than quicksand, which has an approximate specific gravity of 2. For example, a hollow steel ball with a diameter of 5 cm and a specific gravity of 2.5, and will sink in the experiment. Another object needs either as dense or denser than a human but less dense than quicksand. Humans have an approximate specific gravity of 0.95, so a lime with an approximate specific gravity of 1.1 would suffice. Students could even use toothpicks to make made lime “people” with arms & legs to save.

- 10 cm2 piece of cheesecloth

- drain filter to protect sink from overflow sand (paper towels work well in a pinch)

- 1 L container of water to dampen sand from the top of quicksand model

To share with the entire class:

- sink and faucet (use of a laboratory set up with multiple sinks is ideal)

- 4.5 kg of playground sand

- duct tape

- paper towels and cleaning supplies

- waste container for wet sand

- supplies to design and create a prototype structure that prevents a heavy object from sinking in the quicksand; items may include Popsicle sticks, cardboard, straws, aluminum foil, sponges, plastic or paper cups, etc.

- tools to help student build their prototype support structures, including rulers, scissors, permanent markers, and hot glue and glue guns, etc.

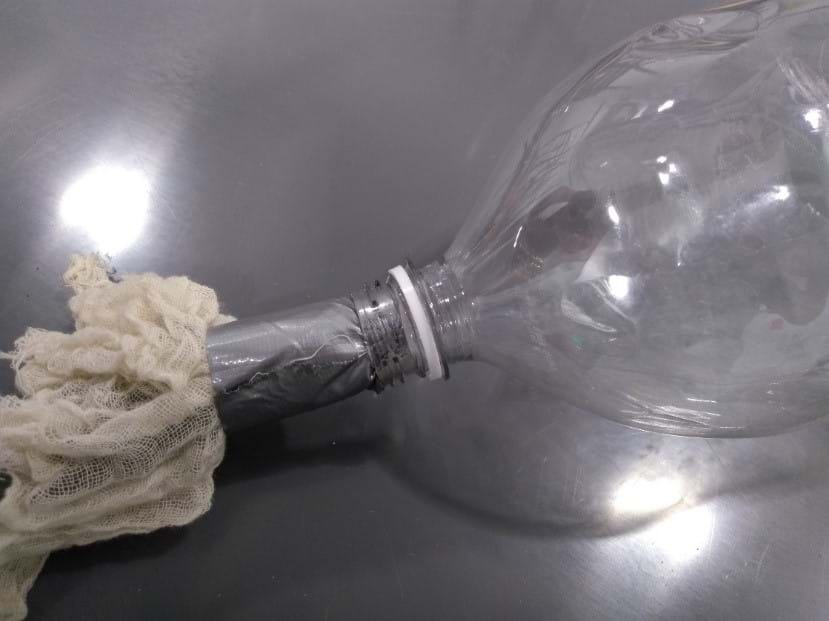

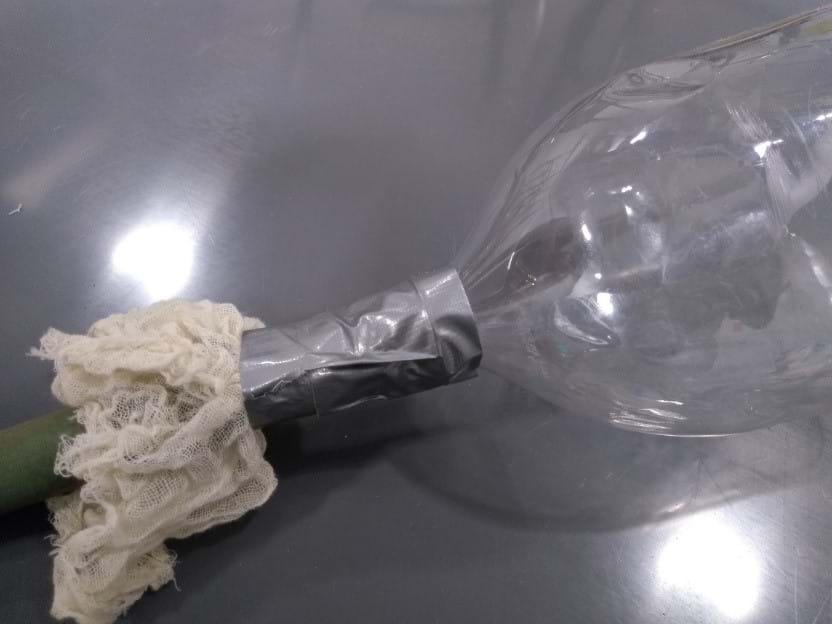

The following images (Image 3, Image 4, and Image 5) show a mock-up of a quicksand testing device in three stages of construction. This example may be used as a model that students can follow for guidance if the groups run out of ideas. This model uses cheesecloth fitted to one end of a flexible tube using duct tube (Image 3). The end with the cheesecloth is inserted roughly 2 cm into the testing container (Image 4). The tube is then taped to the opening of a 2 L plastic bottle (Image 5). The other end of the tube is taped to a faucet (not pictured).

https://www.teachengineering.org/activities/view/cud-2274-quicksand-stress-pressure-liquefaction-design

https://www.teachengineering.org/activities/view/cud-2274-quicksand-stress-pressure-liquefaction-design