Quick Look

Grade Level: 4 (3-5)

Time Required: 30 minutes

30 to 40 minutes

Expendable Cost/Group: US $1.00 $5 or less per class, depending on availability of materials at school

Group Size: 2

Activity Dependency: None

Subject Areas: Physical Science

Summary

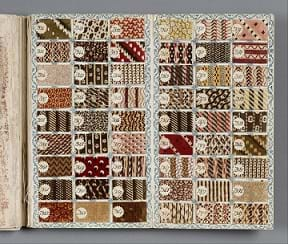

Students examine different types of fabric and their characteristics. Using magnifying glasses and sandpaper, they test and observe the weave and wear quality of fabric samples. By comparing the qualities of different fabrics they come to understand why so many different types of fabric exist and are able to recognize or suggest different uses for them.Engineering Connection

Some engineers design fabrics and other new materials. And other engineers incorporate those fabrics and materials into the products they design. For some product designs, durability over extended periods of time in rough conditions is important. Durable products do not have to be replaced as often, are typically more cost effective, and create less waste. Testing to understand the physical properties of fabrics aids in deciding their best use.

Learning Objectives

- How to use a magnifying glass.

- The structure of fabric.

- Basic experimental testing skills.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

International Technology and Engineering Educators Association - Technology

-

Compare, contrast, and classify collected information in order to identify patterns.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Processing systems convert natural materials into products.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Compare how things found in nature differ from things that are human-made, noting differences and similarities in how they are produced and used.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Describe the properties of different materials.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Create representations of the tools people made, how they cultivated food, made clothing, and built shelters to protect themselves.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Design solutions by safely using tools, materials, and skills.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Identify materials used to accomplish a design task based on a specific property, e.g., strength, hardness, and flexibility.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Differentiate between properties of objects (e.g., size, shape, weight) and properties of materials (e.g., color, texture, hardness).

(Grades

3 -

5)

More Details

Do you agree with this alignment?

Materials List

- magnifying glass

- 3 different pieces of fabric, such as nylon stocking, light-weight cotton, denim

- baseball or other small heavy ball

- extra-coarse sandpaper

- rubber band

- Fabric Wear and Tear Chart, one per student

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/compare_fabric_materials] to print or download.Introduction/Motivation

What do you think your clothes are made of? With your neighbor, make a guess and then check the tags on your clothing to see if you are correct! (Give students time to do this. Write on the board the different fabrics they discover in their own clothing.)

How do you make your clothing choices? Do you go for fashion, function or comfort? Does your choice of clothing change based on the activity you are doing? What would you wear if you were skateboarding, running, playing baseball, ice skating or reading a book?

In today's activity you will study different types of natural and synthetic fabrics and their durability. Who knows, you may end up changing your choice of clothing!

Procedure

Background

Summary of Natural Fibers:

Cotton comes from a cotton boll plant. Woven cloth made of cotton breathes freely, making it comfortable to wear in many kinds of weather. It can be sewn, woven, heated and pressed easily into flannel or used to make knit fabric. Linen is another type of natural fabric. Linen comes from a flax plant. Linen wrinkles easily, but is lightweight, for optimal use in hot weather. Silk is spun by silk worms and can be either smooth or rough. Wool is made from animal hair. Fabric made of wool can provide tremendous warmth. Often, wool is combined with human-made fibers to make outdoor apparel for cold weather.

Summary of Synthetic Fibers:

Polyester is an example of a synthetic fiber used to make cloth. Polyester was popular when first introduced because of the ease of cleaning, durability and wrinkle-free appearance. However, unlike cotton, fiber made of pure polyester does not breath freely, trapping body heat and moisture, which can make it uncomfortable. Rayon is a more delicate fabric; its soft draping quality can look like linen. Rayon is more absorbent than polyester, so it is more comfortable to wear. Another fabric, nylon, is often a part of many fabrics that stretch, like undergarments and swimsuits. Acrylic is another material that can be made into fabric. Acrylic is often used as a wool substitute since it is warm and does not wrinkle easily. Often, acrylic is found in winter outdoor apparel.

Recommended Resources:

http://www.bcomp.ch/10-0-natural-fibres.html

Preparation

- Gather materials.

- Cut each fabric type into 4¼" x 11" pieces.

- Make copies of the Fabric Wear and Tear Chart.

With the Students

Part 1: Observation

- Divide the class into groups of two students each.

- Give each group one piece of each type of fabric.

- Have students use magnifying glasses to look closely at each fabric sample.

- Instruct each group to draw what each fabric weave looks like on the data sheet.

Part 2: Fabric Wear and Tear

- Give each group a baseball.

- Have each group wrap one piece of fabric tightly around the ball and secure with a rubber band. (Note: The tighter the fabric is, the faster the experiment progress.)

- Within each group, have one partner secure a piece of sandpaper (rough side up) on a table top, while the other partner drags the ball across it. DO NOT PRESS DOWN on the ball, just let the weight of the ball drag once across the sandpaper.

Drag the fabric-wrapped ball across the sandpaper. - Use the magnifying glass to observe the area where the fabric was dragged across the sandpaper. Discussion question: Was there any wear after just one scrape?

- Have students continue to test the fabric one scrape at a time. Make a tick mark on the data sheet for each scrape. After each successive scrape, examine the area with the magnifying glass, counting each scrape until you notice some wear on the fabric.

- When students notice some wear on the fabric, have them tally and record the number of scrapes in the chart under "First Wear" for the tested fabric.

- Have students continue scraping the fabric and counting each scrape until they notice a hole or tear.

- Record the number of scrapes in the chart under "Breakthrough" for that fabric.

- Repeat steps 6 -12 for each of the other two fabrics.

Vocabulary/Definitions

breakthrough: A sudden advance in knowledge or technique; a point when a hole is made through a barrier.

fabric: A woven or knitted material/cloth.

fiber: A slender and long natural or synthetic unit of material (such as wool, cotton, asbestos, gold, glass, or rayon) usually able to be spun into yarn.

magnifying glass: A lens that magnifies objects viewed through it.

sandpaper: Paper with rough material (like sand) fixed on one side and used for smoothing and polishing.

thread: A thin fine cord formed by spinning and twisting short fibers into a continuous strand.

wear: Damage, destruction or marks of use made by scraping or rubbing.

wear and tear: The loss or damage that occurs to something during the course of normal use.

weave: Any pattern or method of weaving; to make on a loom by lacing together threads going lengthwise with threads going crosswise.

Assessment

Investigating Questions

- What makes fabrics different?

- Which fabrics are the strongest?

- Why do certain parts of your clothes, such as the knees of pants or the elbows of shirts, wear faster than other parts?

- Which fabric needed the most scrapes to show the first signs of wear?

- Which fabric needed the fewest scrapes to show the first signs of wear?

- Which fabric lasted the longest between the first signs of wear and the breakthrough point?

- Which fabric qualities do you think are the most important for the durability of the fabric? (For example, the type of fiber in the thread, strength of the thread, type or tightness of the weave.)

Activity Scaling

For a more challenging activity, add a discussion about the types of fabric and their various weave designs.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!References

Roy, Richards. "An Early Start to Technology from Science." London, UK: Simon & Schuster, 1990, pp. 66-67.

The Best of WonderScience: Elementary Science Activities. Albany, NY: Delmar Publishers, 1997, pp. 110.

"A Beginner's Guide to Fabrics." Cranston Village, Cranston Print Works. (natural fabrics, human-made fibers, types of cottons, types of silk, types of wool) Accessed July 24, 2001. http://www.cranstonvillage.com/interest/intfeatdetailart.aspx?id=642

Copyright

© 2013 by Regents of the University of Colorado; original © 2004 Worcester Polytechnic InstituteSupporting Program

Center for Engineering Educational Outreach, Tufts UniversityLast modified: May 25, 2017

User Comments & Tips