Quick Look

Grade Level: 7 (6-8)

Time Required: 45 minutes

Expendable Cost/Group: US $5.00

Group Size: 4

Activity Dependency: None

Subject Areas: Physical Science, Science and Technology

NGSS Performance Expectations:

| MS-ETS1-4 |

Summary

Working in teams of four, students build tetrahedral kites following specific instructions and using specific materials. They use the basic processes of manufacturing systems – cutting, shaping, forming, conditioning, assembling, joining, finishing, and quality control – to manufacture complete tetrahedral kites within a given time frame. Project evaluation takes into account team efficiency and the quality of the finished product.

Engineering Connection

From kite racing to hang-gliders, kites have come a long way in the past 2000 years. Then again, even with the information available to us today, kite design is a challenge due to the number of variables associated with it. This activity focuses on the industrial engineering aspect bringing out the importance of efficient manufacturing processes.

Learning Objectives

After this activity, students should be able to understand:

- Basic elements of flight.

- Basic manufacturing systems and processes.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: | Models of all kinds are important for testing solutions. Alignment agreement: The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Use appropriate symbols, numbers, and words to communicate key ideas about technological products and systems.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Manufacturing systems use mechanical processes that change the form of materials through the processes of separating, forming, combining, and conditioning them.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

The manufacturing process includes the designing, development, making, and servicing of products and systems.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Describe and explain the manufacturing systems of custom and mass production.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain basic processes in manufacturing systems, e.g., cutting, shaping, assembling, joining, finishing, quality control, and safety.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify and explain lift, drag, friction, thrust, and gravity in a vehicle or device, e.g., cars, boats, airplanes, rockets.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Recognize that gravity is a force that pulls all things on and near the earth toward the center of the earth. Gravity plays a major role in the formation of the planets, stars, and solar system and in determining their motions.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

- kite string

- glue sticks

- 4 full size sheets of tissue paper per kite

- 7 3/4" tall plastic straws (not the flexible kind), 60 per kite

- pipe cleaners (1 per kite)

- scissors

- poster board or oak tag (1/4 board per kite)

- pencils

- Kite Template & Instructions (attached)

- stopwatches

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/tetrahedral_kites] to print or download.Introduction/Motivation

Do you know how a plane flies? Believe it or not, it is all because of the unique shape of the airplane's wings. Bernoulli's principle states that as the speed of a moving fluid increases, the pressure within the fluid decreases. As the plane flies, the air traveling over and under its wing is considered a fluid. The wings of the plane are designed so that the top of the wing is curved while the bottom of the wing is flat. This creates a longer distance for the air on top of the wing to travel than the air on the bottom of the wing. Since the air on top and bottom of the wing must travel from the front of the wing to the back of the wing at the same time, the air on top of the wing must travel faster to make up for the longer distance traveled. Now applying Bernoulli's principle, because the air on top of the wing is traveling faster, it decreases the pressure on top of the wing. Because there is a lower pressure on top of the wing and a higher pressure on bottom of the wing, it creates an unequal force on the wing causing it to lift, thus allowing the plane to fly.

In today's activity, you will apply this mechanism of flight to designing tetrahedral kites. Working in teams of four, you will build a tetrahedral kite following a specific set of instructions and using specific provided materials. You will use basic processes found in many manufacturing systems - cutting, shaping, forming, conditioning, assembling, joining, finishing, and quality control - to manufacture a complete tetrahedral kite within a given time frame. Pay attention to your team's efficiency, the quality of the finished kite and the time limit. Testing of the kites is simple, we will time how long it stays in flight.

Procedure

Background

Newton's third law of action and reaction states that for every action there is an equal and opposite reaction.

Bernoulli's principle is the conservation of energy for flowing fluids with little to no viscosity. In the case of a plane or kite flying in the air, it states that as a fluid such as air passes below a wing, air also passes above it. The air on the top of the wing moves a longer distance over the curved surface of the wing, thus it moves faster reducing the pressure above the wing. The air below the wing moves more slowly causing the air pressure below the wing to be larger than the pressure above the wing. It is the change in relative pressures above and below the kite that allows the kite to lift.

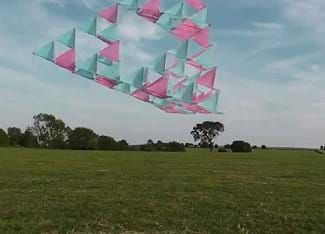

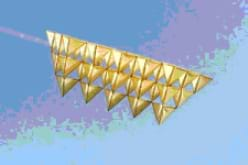

Kites were the first flying devices ever made by humans. The word "kite" comes from a bird in the hawk family known for its grace in the air. Kites come in a wide variety of shapes and sizes and have been used for many purposes throughout history, although today, kite flying is done largely for recreation. See Figure 1 for an example of a tetrahedral kite, the type that students will be manufacturing in the activity.

Recommended Resources:

https://www.kite.org/about-kites/history-of-kites/

http://www.intellicast.com/KITEcast/Windandkites/

http://www.skratch-pad.com/kites/fly.html

Preparation

- Gather materials.

- Make copies of the Kite Template & Instructions.

With the Students

Phase 1: Making Pyramids

- Obtain six straws, measure and cut a 72" (182.88 cm) long piece of kite string. Thread 4 straws on the kite string. Hold on to the ends. Keep approximately 3" (7.62) of string towards end A.

- Arrange the straws onto a diamond shape and use the pipe cleaner "needle" to feed the string through the starter straw, so that it comes out between straw 1 and straw 2.

- Add the fifth straw and place it across the center of the diamond.

- Feed the "needle" back through the third straw so that it comes out between straw 2 and 3.

- Add the sixth straw. Pull up the straws so that a triangle is formed. Tie it off so that your triangles form a stable pyramid shape. Now, using steps 1-5 make 9 more pyramids!

Phase 2: Building the Kite

Pictures of each step can be seen at http://ford.berea.k12.oh.us/Kitewebpage/Tetra.htm (Ref. 1).

- Using the template, carefully trace and cut out 20 tissue paper shapes.

- Cover two sides of each pyramid with tissue paper. Fold the edges of the tissue paper around the straw and glue in place.

- Assemble the kite. Begin with the bottom layer. Arrange three pyramids side by side so that they only touch by one corner and the front of each is a covered panel (all of the covered panels should lie in a plane). The other covered panel should be lying flat on the table. Knot the pyramids at the points where they meet. Arrange two pyramids behind those three so that the front covered panels of the two new pyramids faces the same direction as the front three. The back corners of the front three just meet the front corners of the two behind. Knot the two pyramids at all points that touch. Attach one more pyramid to the back corners of the row with two, again facing the covered panel forward. Be sure that all knots are secure!

- Add the second layer of pyramids. Arrange two pyramids side by side (make sure the covered panels are on the bottom and front). Knot them to each other. Align the bottom corners of these two with the peaks of the front five pyramids on the bottom layer. Knot these two pyramids to the bottom layer. Arrange and attach a third triangle behind the two you just attached. Be sure that all knots are secure!

- Add the third and final layer. Attach a single pyramid on top of the second level still having the covered panel facing forward. The finished kite itself looks like a giant pyramid. Be sure that all knots are secure!

- Attach kite strings to the corners where the front panel meets the back panel. With the strings here, the panels will face downward when in flight and the triangles will look like birds in flight.

- Add a tail to keep the kite properly oriented towards the wind.

Phase 3: Flying Your Kite

- Check the knotting. Attach flying string. Go out and fly your kite!

- Start a stopwatch as soon as you let go of your kite (or when your partner lets go), and then stop the stopwatch when the kite touches down on the ground. This will be a "fair test" as long as the wind does not change too much. Groups may see improvement in flight time as they modify and improve their kite design.

Phase 4: Analysis of Manufacturing

Gather the class for a concluding discussion. Ask the Investigating Questions, and the following questions:

- How well did your team work together to build your kite? Were you efficient? Where was time wasted? What were the problems?

- Which improvement made for the largest difference in flight time?

- Did you follow the specific instructions and use the specified materials? Did you finish on time? How was the quality of the end product?

- Describe all the basic manufacturing system processes you used (cutting, shaping, forming, conditioning, assembling, joining, finishing, and quality control).

- What improvements would you make to the the kite-making process?

- What is industrial engineering? (After listening to student suggestions, read the definition.) How is the kite-making your team did today a type of industrial engineering?

Vocabulary/Definitions

drag: A frictional force acting on a body (as an airplane) moving through a fluid (as air) parallel and opposite to the direction of motion.

gravity: A force of attraction between two objects due to the mass of the objects and the distance separating them.

industrial engineering: A branch of engineering dealing with the optimization of complex processes or systems. It is concerned with the development, improvement, implementation and evaluation of integrated system. The term originally applied to manufacturing, but has grown to encompass any methodical or quantitative approach to being efficient in how a process, system or organization operates.

lift: The component of the total aerodynamic force acting on an airplane or airfoil that is perpendicular to the relative wind and that for an airplane constitutes the upward force that opposes the pull of gravity.

relative wind: The airflow produced by the aircraft moving through the air. The relative wind is in a direction parallel with and opposite to the direction of flight.

tension: Two pulling forces directly opposing each other that stretch an object. Tension in the string keeps a kite from flying away.

Assessment

Example performance evaluation rubric criteria:

4 (Advanced) Project exceeds guidelines set by teacher

3 (Proficient) Project meets guidelines

2 (Developing) Project meets some guidelines

1 (Beginning) Project fails to meet guidelines or is incomplete

0 Project not attempted

Use of flight time is a simple quantitative way to track kite design improvements.

Investigating Questions

- How and why do objects move upward?

- Why do kites fly?

- How can a team of students most efficiently produce a finished product – the tetrahedral kite – using manufacturing processes?

- How will modifications of the project's initial design alter the kite's performance?

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are introduced to the concept of air pressure. They explore how air pressure creates force on an object. They study the relationship between air pressure and the velocity of moving air.

Students learn about kites and gliders and how these models can help in understanding the concept of flight. Then students move on to conduct the associated activity, during which teams design and build their own balsa wood glider models and experiment with different control surfaces, competing for ...

Students revisit Bernoulli's principle (presented in lesson 1 of the Airplanes unit) and learn how engineers use this principle to design airplane wings. Airplane wings create lift by changing the pressure of the air around them. This is the first of four lessons exploring the four key forces in fli...

Copyright

© 2013 by Regents of the University of Colorado; original © 2004 Worcester Polytechnic InstituteSupporting Program

Center for Engineering Educational Outreach, Tufts UniversityLast modified: July 30, 2021

User Comments & Tips