Quick Look

Grade Level: 9 (9-12)

Time Required: 1 hours 30 minutes

(two 45-minute class periods)

Expendable Cost/Group: US $20.00 The activity also uses non-expendable (reusable) items, such as K'NEX parts and pieces, glue guns and hammers; see the Materials List for details.

Group Size: 5

Activity Dependency: None

Subject Areas: Physical Science, Problem Solving

NGSS Performance Expectations:

| HS-ETS1-2 |

Summary

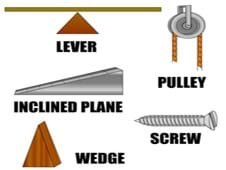

Refreshed with an understanding of the six simple machines; screw, wedge, pully, incline plane, wheel and axle, and lever, student groups receive materials and an allotted amount of time to act as mechanical engineers to design and create machines that can complete specified tasks. For the competition, they choose from pre-determined goal options such as: 1) dumping goldfish into a bowl, 2) popping a balloon, or 3) dropping mint candies into soda pop (creating a fizzy reaction). Students demonstrate their functioning contraptions to the class, earning points for using all six simple machines, successful transitions from one chain reaction to the next, and completion of the end goal.

Engineering Connection

Students act as mechanical engineers to design and create machines that combine multiple parts and functions to ultimately complete goals. Even if the Rube Goldberg machine steps are silly and inefficient, they parallel the work of mechanical engineers who design and create machines to complete the tasks of our human lives. For example, for cars to operate as intended, mechanical engineers must design each part to work perfectly with all the other vehicle parts with which it interacts. The steering wheel must correctly work with the axle and wheels (an example of a simple machine) so that the vehicle can be turned. Engineers follow the steps of the engineering design process to ensure that designs meet specified requirements and constraints. Even after a successful test of a design, engineers go back through the process to determine how to make the design work even better.

Learning Objectives

After this activity, students should be able to:

- Describe the six simple machines and create a design that incorporates them all.

- Use given materials and apply engineering skills to create a physical, functioning machine that completes a specified goal.

- Work collaboratively as a team to build a complex device that incorporates at least one of each of the six simple machines: incline plane, screw, pulley, wheel and axle, lever, and wedge.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Michigan - Science

-

Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- plywood base, 4 foot x 4 foot (1.2 m x 1.2 m)

- 500-piece K'NEX®, a construction toy that includes bricks, rods and connectors for open-ended building, available at Amazon

- 20 paper plates

- 1 bag Pepperidge Farm® Goldfish® crackers

- 1 roll yarn

- 1 roll duct tape

- 1 roll scotch tape

- 1 sleeve Mentos® mint candies

- 20 pieces paper

- 6 wooden boards, 2 of each length .5, 1, 1.5 foot (15 cm, 30 cm, 46 cm)

- 4-foot (1.2-m) piece of corner edging

- 20-oz (590-ml) diet soda, such as Diet Coke®

- 4 mouse traps

- 1 box toothpicks

- 20 dominoes

- 6 magnets

- 20 pipe cleaners

- 1 pulley

- 1 toy car

- 20 paper cups

- 2 screws

- 2 small dowels

- 20 rubber bands

- 10 balloons

- 5 marbles

- 2 foam tubes, wide enough that marbles can fit inside

- wooden wedge

- dowel pieces, 1-inch diameter, 2 of each length: 0.5, 1, 1.5 inch (1.27 cm, 2.54 cm, 3.81 cm)

- scissors

- hammer and box of nails

- staple gun and box of staples

- hot glue gun and 7 hot glue sticks

- Grading Rubric

To share with the entire class:

- computer with internet connection and projector, to show short YouTube videos

Note: Adding or subtracting materials from this list is acceptable. However, providing a larger range of materials allows students to be more creative in the design of their machines! It is important for the competition that each group has the exact same materials.

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cmu_rube_activity1] to print or download.Pre-Req Knowledge

Students should be able to identify the six simple machines and describe how they work. It is not necessary that students have manipulated them before, although it may be helpful. With some explanation students may find they have used the various machines before, for example:

- Screw, such as a twist-off lid or a screw use to attach materials together

- Wedge, such as a doorstop used to keep open a door

- Pully, such as a tow truck winch used to lift up a car

- Incline plane, such as descriptions of how ancient Egyptian pyramids were built by pushing blocks up ramps to the pyramid top

- Wheel and axle, such as skateboard and bicycle wheels or door knobs

- Lever, such as playground seesaws, prying a nail out of wood by using the claw end of a hammer or opening a can of paint with a flat screwdriver

Students should understand the main steps of the cyclical engineering design process: ask, research, imagine, plan, create, test and improve.

Introduction/Motivation

Working as a team, you will use a set of provided materials to create a machine that utilizes all of the six simple machines. Each simple machine is used to make life easier in some way. Let's review them.

An incline plane, or a ramp, provides a flat surface that is at an angle to the horizontal ground. Traveling along an incline plane enables objects to be moved to a higher point without having to lift them straight up. This increases the distance the object needs to be moved, but reduces the force required because of less opposition from gravitational force. Inclined planes make the work of moving things easier. One example that you may of heard about is the use of ramps to build the ancient pyramids. Egyptions pushed the giagantic blocks up ramps to the top of the pyramid. Today, ramps are often used to lift heavy objects, such as moving furniture from the ground into a truck or van.

A wedge is a simple machine that can be made of two inclined planes or a curved surface reaching a sharp point. Wedges are used to split, cut or put holes in an object. One example is a nail, which has a small, sharp tip and and a larger body. A nail is always hammered into a piece of wood tip first because the tip can split through the wood, working as a wedge. Another example is an axe blade used to chop wood. Its tip is thin, so it can get into the wood; then, as the larger part of the axe blade is forced in into the wood, it has an outward force large enough to split the wood apart.

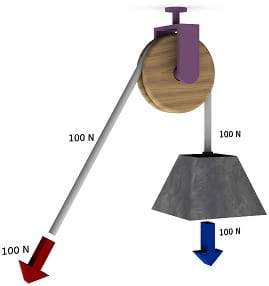

A pulley is a combination of a solid loop and a roller. A pulley reduces the friction of pulling an object up and also allows a pulling motion to lift an object. Examples include hanging a deer for skinning or a weight lifting machine in a gym, in which you pull down on a bar that is connected to a wire that goes through a pulley and connects to the weight, pulling it up.

A screw is a simple machine that works to hold something in place. If you look closely, you can see that a screw is composed of two other simple machines—an inclined plane and a wedge. The tip of the screw is the wedge and the thread of the screw is a very long inclined plane wrapped around the main cyclinder body of the screw. The wedge tip enables the screw to make a hole in wood, for example, and then, once the threads are inside the wood, they hold the screw inside the wood. Other examples are the twisting lid on a jar and a machine vise that tightly clamps a board in place.

A wheel and axle is composed of a rod attached to a wheel, which is generally much larger in diamater than the axle. The axle is rotated in order to turn the wheel. The smaller radius of the rod can be turned with a smaller force then the whole wheel, so by turning the axle the larger wheel can be more easily rotated. A few examples are wheels on vehicles, skateboards and bikes. The axle of a Ferris wheel enables the entire huge wheel, holding all of the dangling passenger seats at its rim, to turn.

A lever is a long straight object that is used to lift something with less force then would otherwise be necessary. A smaller force on the longer end of the rod, based on the fulcrum (the point that the rod pivots on) becomes a larger force on the shorted end of the rod that is prying something up. Levers may be the most common simple machine because just about anything with a handle serves as a lever. Examples are a playground seesaw, or using the claw end of a hammer to pry a nail out of a piece of wood. The nail could not be pulled straight out, but using the lever of the hammer a little bit of force initially can lead to a larger force acting to pull out the nail.

Your task today is somewhat like the work of mechanical engineers who create designs so that an assortment of parts work together to accomplish a goal—such as the steering on a car, the levers that move the gears in your bicycle, the functioning of a replacement (prosthetic) hand, or the buttons that control your phone.

In groups, you will act as mechanical engineers to create multi-step machines that complete a specified task and incorporate the simple machines, operating on their own.

(Show students a few short YouTube videos of elaborate and fun example Rube Goldberg contraptions. See the suggested videos in the Additional Multimedia section.)

Our machines will be on a much smaller scale, but just as you saw in the videos, you are permitted to only touch the machine to start it; the rest of the movement must be completely self-sufficient.

(If time permits, as a class, go back through one of the videos and, pausing when needed, identify all the simple machines that were used.)

In today's project you will also be following the steps of the engineering design process. Do you remember what they are? (Listen to student answers. Write them on the board.) That's right, identify a task, research, imagine, plan, create a prototype, test and evaluate, and improve as needed. The engineering process is cyclical. Steps can be skipped and returned to in both directions—since engineers' work is never done because improvements can always be made! Think about how you can apply these steps to your project today.

Procedure

Background

Once students are refreshed on the six simple machines and how they work, ask them to provide everyday examples of how they are used. Then provide groups with materials and an allotted amount of time to create machines that can complete one of three goal options such as: 1) dump goldfish into a bowl, 2) pop a balloon or 3) drop mint candies into soda pop.

For this open-ended, higher-level thinking activity, encourage creativity but enforce the time limitation. Do not micromanage how students create their machines; an unlimited number of successful solutions exist. If groups get waylaid, have them refer back to the steps of the engineering design process to see where they are, see how much time is left, and focus on essential items on the rubric to meet the end goal. The primary design process steps are: ask to identify a task, research, imagine possible solutions, plan, create a prototype, test and evaluate, and improve as needed.

In the interest of time efficiency, consider having students brainstorm outside of the class period or in the evening between the two class periods. For building and testing, give students the rest of the first class period and all but 15 minutes of the second class period.

Once machines are completed, groups demonstrate them to the rest of the class. Use the rubric to award points for including each simple machine at least once, successful transitions and goal completion.

Before the Activity

- Collect all the materials and divide them up evenly for each group.

- Make copies of the Grading Rubric, one per group.

- Pre-determine groups of five students, so that each group has an even skill level. Tip: Do not put all top students in one group.

With the Students

- Present students with the Introduction/Motivation content to provide a brief overview of the six simple machines and recap the steps of the engineering design process. As necessary for the knowledge level of your class, show students how each machine works.

- Divide the class into the pre-determined groups.

- Hand out materials, tools and a grading rubric to each group.

- Explain the design challenge: Use the given materials within the time limitation to create a Rube Goldberg machine that includes as many of the six simple machines as possible to achieve one of the three goal options. You may only touch the completed machine to start it; the rest of the movement must be completely self-sufficient.

- (optional) Show students photographs and videos of example student-created Rube Goldberg machines from conducting this activity at a high school in Michigan. See the websites in the Additional Multimedia Support section.

- In their groups, have students brainstorm ideas and draw their plans in some detail before starting to build. Give students the rest of the period and all but 15 minutes of the second class period to plan, construct, test and improve their machines.

- As students are constructing, go around the room and ask what they are building and where the simple machines come into play—to make sure they are not forgetting about them!

- After time is up (with 15 minutes left in the second class period), have each group point out each simple machine that is incorporated into its Rube Goldberg machine, and then demonstrate it for the rest of the class. While groups are demonstrating their machines, fill out a grading rubric for each, as described in the Assessment section. Announce the winning team.

- Conclude by having students sort and clean-up materials for trash and recycling, and returning tools to safe storage.

Vocabulary/Definitions

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. The engineering process is cyclical, and steps can be skipped and returned to in both directions.

inclined plane: A flat surface that is higher on one end. Used to move an object to a lower or higher place. Less energy and force is needed to move objects via an inclined plane. Examples: ramp, slide.

lever: A long straight object that pivots or moves back and forth at a certain point (called the fulcrum). By changing the position of the fulcrum, extra power can be gained with less effort. Examples: seesaw, hammer prying out a nail.

pulley: A simple machine that uses a grooved wheel(s) and a rope to raise, lower or move a load.

Rube Goldberg: A complex machine that performs a simple task, often in a laborious and comical fashion; named after the cartoonist and engineer who poked fun at overly complicated machines.

screw: An inclined plane wrapped around a rod. Screws are used to hold things together. Examples: clamps, spiral staircases.

wedge: A "v" shape that helps to push things apart. Examples: knife and shovel blades, nail tip.

wheel and axle: A simple machine composed of a rod that is attached to the center of a wheel. Rotating the axle assists and allows the wheel turn.

Assessment

Pre-Activity Assessment

Simple Machines Review: As a class discussion, ask students to name the six common types of simple machines, explain how they work and provide examples of how each is used. (Example answers: A screw might be a twist-off jar lid or a screw that attaches two pieces of wood together. A wedge might be a doorstop used to keep a door open or a snowplow's blade. A pulley is often used to hang a deer carcass or as part of a tow truck winch that lifts a car's wheels off the ground. An incline plane is often used to push something up a hill, which is easier than lifting it straight off the ground, such as a handicap ramp to enter a building. Wheels and axles are commonly part of vehicles, but also in door knobs and merry-go-rounds. A lever is at work in the playground seesaw, opening a can of paint with a flat screwdriver, or using the claw end of a hammer to pry a nail out of a piece of wood.)

Activity Embedded Assessment

Engagement Questions: While students are engaged in constructing their machines, circulate the classroom and ask them questions to increase their awareness and reflection, and keep them on task. Ask the students:

- How are you using the six simple machines? (Answers will vary. Look for examples such as using wedges to prop up items, inclines to roll down items, pulleys to raise something while lowering something else, etc.)

- What are you going to do to reach your goal? (Expect students to be able to describe how their machines are intended to function. For example, the marble leaves the ramp and causes the cup to tip over.)

- At what step of the engineering design process are you working in now? (Expect answers to include one of the following stages: planning, building, testing, redesigning, rebuilding or retesting.)

Post-Activity Assessment

Final Demos: Use a Grading Rubric to evaluate each group project. Check off which simple machines were included, whether or not they worked or transitioned successfully, and if the machine as a whole met its ultimate goal. Expect all team members to be able to explain their machines, including pointing out each simple machine included and how it qualifies and contributes to the functioning of the machine. (Example: This wedge props up a bucket so all the soda pop stays in one end. The ball rolls down this incline plane to move the ball from a high place to a low place more slowly than just falling straight down.)

For purposes of the competition, the rubric provides an all-or-none type of grading. When it asks, "did it work?"—it is literally asking whether a screw was successful or if the wedge did what students intended it to do. So give every section a yes or no rating—no partial points.

While the grading rubric serves to compare machines for purposes of the competition, it does not necessarily reflect the grade that an individual student deserves. It is recommend that students receive full credit (in terms of their individual grades) for participation, tempered with teacher observations of their engagement and contributions to the project in the form of ideas offered, collaboration efforts, construction work and presentation explanations.

Safety Issues

- Review with students all safety precautions and procedures for use of the hammers, glue guns and staple guns.

Activity Extensions

Give students time to go through another iteration or two of the engineering design process based on the results of their Rube Goldberg machine performances. Have students identify any problems that occurred during the demonstration and redesign their machines to address those issues or incorporate new, improved aspects. After students rebuild their machines, retest via class demonstrations.

Additional Multimedia Support

Show students these elaborate and entertaining Rube Goldberg contraption YouTube videos:

- OK Go-This Too Shall Pass Rube Goldberg Machine Version (3:54 minutes; starts with a toy truck knocking down a row of dominoes and ends by throwing paint at four band members): https://www.youtube.com/watch?v=qybUFnY7Y8w

- Honda All Physics Rube Goldberg Project Setup (2:26 minutes; a TV commercial that starts with a rolling gear that triggers a series of events using car parts): https://www.youtube.com/watch?v=dOJIE4S5uaY

Show students videos of example student-created Rube Goldberg machines from conducting this activity at a high school in Michigan. See videos at https://sites.google.com/site/cmunsfresearchproject2012/high-school-classroom-visits/rube-goldberg-john-glenn-high-school.

See additional lessons and activities involving Rube Goldberg machines by searching the TeachEngineering digital library, such as Rube Goldberg and the Meaning of Machines > Design and Build a Rube Goldberg.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are introduced to the six types of simple machines — the wedge, wheel and axle, lever, inclined plane, screw, and pulley — in the context of the construction of a pyramid, gaining high-level insights into tools that have been used since ancient times and are still in use today.

Students are introduced to three of the six simple machines used by many engineers: lever, pulley, and wheel-and-axle. In general, engineers use the lever to magnify the force applied to an object, the pulley to lift heavy loads over a vertical path, and the wheel-and-axle to magnify the torque appl...

Students explore building a pyramid, learning about the simple machine called an inclined plane. They also learn about another simple machine, the screw, and how it is used as a lifting or fastening device.

In this lesson, students learn about work as defined by physical science and see that work is made easier through the use of simple machines. Already encountering simple machines everyday, students will learn about their widespread uses in improving everyday life.

References

Simple Machines (vocabulary). NASA Event Catalog. Accessed June 25, 2013. http://www.nasa.gov/offices/education/programs/national/dln/events/Simple_Machines.html

Copyright

© 2013 by Regents of the University of Colorado; original © 2012 Central Michigan UniversityContributors

Jackie SwansonSupporting Program

RET Site on Multidisciplinary Engineering Research for Rural Michigan's Future, Central Michigan UniversityAcknowledgements

This curriculum was developed under National Science Foundation Research Experience for Teachers grant no. EEC 1201095. However, these contents do not necessarily represent the policies of the National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: November 2, 2021

User Comments & Tips