Quick Look

Grade Level: 5 (4-6)

Time Required: 45 minutes

Expendable Cost/Group: US $3.00 This activity also requires non-expendable (reusable) LEGO robots and software; see the Materials List for details.

Group Size: 5

Activity Dependency: None

Subject Areas: Measurement, Physics, Science and Technology

NGSS Performance Expectations:

| 3-5-ETS1-1 |

| 3-5-ETS1-3 |

Summary

Students learn about nanocomposites, compression and strain as they design and program robots that compress materials. Student groups conduct experiments to determine how many LEGO® MINDSTORMS® motor rotations it takes to compress soft nanocomposites, including mini marshmallows, Play-Doh®, bread and foam. They measure the length and width of their nanocomposite objects before and after compression to determine the change in length and width as a function of motor rotation.Engineering Connection

Many types of engineers design and build robots to complete tasks. For example, some biomedical and computer science engineers design robots that perform surgery on patients or measure patients' vital signs. Some biomedical and chemical engineers design material-based robots that combine multiple components to generate composites with various functions—such as drug delivery, tissue engineering and scaffold design—that are responsive to stimulations in an environment. Electrical and mechanical engineers often work together to design smart items—trashcans, coffee makers, slow cookers and microwaves--that simplify everyday tasks.

Learning Objectives

After this activity, students should be able to:

- Design and build a LEGO robot capable of compressing an object.

- Program a robot with LEGO software.

- Open up the MINDSTORMS data logging program with the rotation sensor and find out how many motor rotations it takes to compress a given object.

- Calculate the ratio of strain on an object using Equation 1, where L is the length of the object being deformed and Lchange is the change in length of the deformed object.

Equation 1: strain = (Lchange)/ L

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-1. Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a simple design problem that can be solved through the development of an object, tool, process, or system and includes several criteria for success and constraints on materials, time, or cost. Alignment agreement: | Possible solutions to a problem are limited by available materials and resources (constraints). The success of a designed solution is determined by considering the desired features of a solution (criteria). Different proposals for solutions can be compared on the basis of how well each one meets the specified criteria for success or how well each takes the constraints into account. Alignment agreement: | People's needs and wants change over time, as do their demands for new and improved technologies. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-3. Plan and carry out fair tests in which variables are controlled and failure points are considered to identify aspects of a model or prototype that can be improved. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Plan and conduct an investigation collaboratively to produce data to serve as the basis for evidence, using fair tests in which variables are controlled and the number of trials considered. Alignment agreement: | Tests are often designed to identify failure points or difficulties, which suggest the elements of the design that need to be improved. Alignment agreement: Different solutions need to be tested in order to determine which of them best solves the problem, given the criteria and the constraints.Alignment agreement: | |

Common Core State Standards - Math

-

Fluently add and subtract multi-digit whole numbers using the standard algorithm.

(Grade

4)

More Details

Do you agree with this alignment?

-

Find whole-number quotients of whole numbers with up to four-digit dividends and two-digit divisors, using strategies based on place value, the properties of operations, and/or the relationship between multiplication and division. Illustrate and explain the calculation by using equations, rectangular arrays, and/or area models.

(Grade

5)

More Details

Do you agree with this alignment?

-

Represent real world and mathematical problems by graphing points in the first quadrant of the coordinate plane, and interpret coordinate values of points in the context of the situation.

(Grade

5)

More Details

Do you agree with this alignment?

-

Perform operations with multi-digit whole numbers and with decimals to hundredths.

(Grade

5)

More Details

Do you agree with this alignment?

-

Fluently add, subtract, multiply, and divide multi-digit decimals using the standard algorithm for each operation.

(Grade

6)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Requirements for design are made up of criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Analyze examples of technologies that have changed the way people think, interact, and communicate.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Create solutions to problems by identifying and applying human factors in design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

New York - Math

-

Perform operations with multi-digit whole numbers and with decimals to hundredths.

(Grade

5)

More Details

Do you agree with this alignment?

-

Find whole-number quotients of whole numbers with up to four-digit dividends and two-digit divisors, using strategies based on place value, the properties of operations, and/or the relationship between multiplication and division. Illustrate and explain the calculation by using equations, rectangular arrays, and/or area models.

(Grade

5)

More Details

Do you agree with this alignment?

-

Represent real world and mathematical problems by graphing points in the first quadrant of the coordinate plane, and interpret coordinate values of points in the context of the situation.

(Grade

5)

More Details

Do you agree with this alignment?

-

Fluently divide multi-digit numbers using the standard algorithm.

(Grade

6)

More Details

Do you agree with this alignment?

-

Fluently add, subtract, multiply, and divide multi-digit decimals using the standard algorithm for each operation.

(Grade

6)

More Details

Do you agree with this alignment?

New York - Science

-

Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Plan and carry out fair tests in which variables are controlled and failure points are considered to identify aspects of a model or prototype that can be improved.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- LEGO MINDSTORMS NXT robot, such as the NXT Base Set (5003402) for $159.98 at https://shop.education.lego.com/legoed/en-US/catalog/product.jsp?productId=5003402& isSimpleSearch=false&ProductLine=NXT

- LEGO MINDSTORMS Education NXT Software 2.1, available as a single license (2000080) for $39.97 or a site license (5003413) for $271.96 at https://shop.education.lego.com/legoed/en-US/catalog/product.jsp?productId=prod120017&isSimpleSearch=false&ProductLine=LEGO+MINDSTORMS+Education+NXT

- computer, loaded with NXT 2.1 software

- LEGO MINDSTORMS NXT Intelligent brick (in addition to the one provided in the kit above), part # 9841, available for $169.99 at http://shop.lego.com/en-US/NXT-Intelligent-Brick-9841?CMP=AFC-BP6648365778&HQS=9841

- calculator

- ruler

- mini marshmallow

- piece of Play-Doh (about the same size as a mini marshmallow)

- piece of foam (such as Styrofoam, about the same size as a mini marshmallow)

- piece of bread (about the same size as a mini marshmallow)

- Deformation: Foam Compression Worksheet, one per student

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/nyu_deformation_activity1] to print or download.Pre-Req Knowledge

Students should be familiar with multiplication, division, and the basic concept of a function.

Introduction/Motivation

Take a look around and notice that you are continually surrounded by materials of different sizes and shapes. Some materials can take on different shapes or forms when they are dropped on the floor, stepped on or compressed! The term compression is often used to describe the decrease in volume of an object.

Today we're going to talk about and experience compressing a specific material type called nanocomposites. Nanocomposite is a big word, but you are already familiar with (and have probably compressed) the soft, human-made nanocomposites that we will use in the activity: marshmallow, Play-Doh, bread and foam.

A nanocomposite is simply the result of multiple materials combined together to make a nano-sized material. Some of the most fascinating materials found in nature—arthropods exoskeletons, mollusks, marine worm teeth and human bone—are nanocomposites that engineers are inspired to recreate using synthetic materials.

Why would engineers bother to make nanocomposites? Well, because they have some kind of desirable quality—perhaps cosmetic, structural or functional—that makes them useful or wanted in some way, just like the fun, squishy texture of a marshmallow or Play-Doh!

In today's activity, you will design, build, and program LEGO NXT robots to compress the soft nanocomposites I just mentioned: marshmallows, Play-Doh, bread and foam. Then, you will get to determine the amount of compression you applied to each material by using a rotation sensor with the MINDSTORMS data logging program.

Procedure

Background

Materials chemists and engineers are continually learning more about material properties, such as how much stress a material can undergo before changing its shape. Stress is simply defined as the amount of force applied to a material over a certain area. Strain is the amount that a material expands after a stress is applied to a material. In this activity, students determine the amount of strain on test materials by measuring their change in length following compression (see Equation 1).

Before the Activity

- Gather materials.

- Make copies of the Deformation: Foam Compression Worksheet.

- Consider building an example robot in advance, using the LEGO Digital Designer (LDD) Compressor Robot Instructions.

With the Students

- Distribute the worksheets.

- Teach students the vocabulary words and have them fill out the "pre-activity" section of the worksheets (defining stress and strain).

- Explain the activity: Each group is responsible for designing and building a robot capable of compressing a mini marshmallow, as well as similarly-sized pieces of Play-Doh, bread and foam.

- Give students time to fill out the "hypothesis," "materials" and "procedure" worksheet sections.

- Divide the class into groups of four students each. Assign roles to the group members of each team:

- Robot Worker - makes changes to the robot

- Program Worker - programs the robot and uses the data logging program to record the number of motor rotations for each compression

- Measurer - measures changes in length of the object before and after compression

- Calculator - calculates the strain on each object

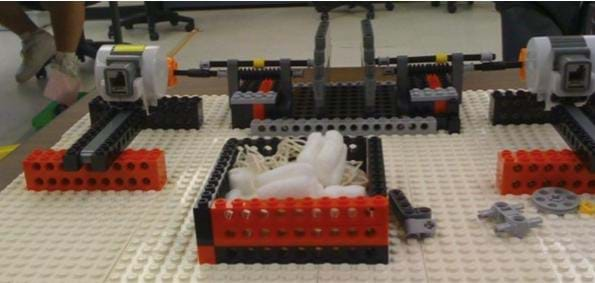

- Remind students of the activity objective (to design and build a robot that can compress the test material samples). If available, show them an example robot. Depending on time constraints and/or student ability, either encourage students to design their robots through trial and error or give them ideas from the pictures included in this activity.

- Direct students to program their robots using the LEGO Digital Designer (LDD) Compressor Robot Instructions.

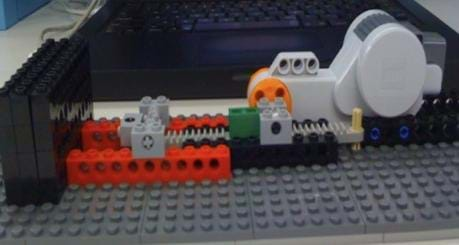

- Remind students to plug their cables into motor A, located on the NXT brick. The LEGO MINDSTORMS program should look like Figure 1. Explain that they can program the motors to move more quickly or slowly and can specify the amount of time it runs by clicking on "motor" in the LEGO MINDSTORMS NXT application.

Figure 1. Program image for the activity's compression robot. - Before moving on, require each group to demonstrate that its robot is capable of compressing an object.

- Go over the MINDSTORMS data logging program with students and show them how the rotation sensor works. (For help with the data logging program, see this YouTube video). Show students how to open the program, choose motor A, and select the rotation sensor to see how much the motor rotates.

- Have student groups guess how many motor rotations it will take their robots to compress each of the four test materials.

- As an example, demonstrate compression of the test materials for the class using one group's robot or the example robot built in advance. Ask students to make predictions and observations about the number of motor rotations it takes to compress a chosen demo object. Show them how to use a ruler to measure the length and change in length of the object. Go over Equation 1 and teach them how to calculate strain using the example measurements. Demonstrate how to find out how many times the motor rotated by selecting the rotation sensor in the MINDSTORMS data logging program. Ask students how their predictions compared with the actual motor rotations.

An example robotic compressor designed by a student group. - Tell students they are now responsible for repeating the same procedure for their four test materials, as well as filling out the "data" worksheet section. Give groups time to gather data. Circulate the classroom to answer questions as they work.

- Have students reflect on their findings and fill out the "results/conclusion" worksheet section.

- Facilitate a class discussion to compare group findings and discuss what students learned from the activity.

- Conclude by administering the post-activity assessment described in the Assessment section.

Vocabulary/Definitions

compression: A system of forces that decrease the volume of an object.

deformation: When an object gets changed due to an internal or external force.

force: A push or pull exerted on an object.

length: The measure of how long something is from one end to another.

nanocomposite: A solid material less than 100 nm in size with multiple phases and dimensions.

nanometer : (nm) A nanometer is a unit of length that is 1 billionth of a meter. Nanocomposite materials are measured in nanometers.

rotation sensor: A LEGO MINDSTORMS NXT device that can measure rotation of an axle (16 positions per rotation).

strain: The change in dimensions of an object when influenced by an external force.

stress: The amount of force exerted on a specified area.

Assessment

Pre-Activity Assessment

Guessing Game: Ask students to predict which of the provided materials will require the most rotations to compress.

Activity Embedded Assessment

Data, Results and Conclusions: Have students complete the Deformation: Foam Compression Worksheet with their observations, measurements and calculations. Review their answers to assess their understanding.

Post-Activity Assessment

Tuning the Equation: Challenge students by asking them to relate the strain of an object to the stress on an object. See if they can make an equation that relates stress to strain. (Answer: Young's modulus measures the stiffness of a material by looking at how much the material stretches under a given amount of stress. Young's modulus states that stress is proportional to strain in the equation below (Equation 2).

Equation 2: E (Young's modulus) = σ (stress) / є (strain)

Investigating Questions

- The materials in this activity can be viewed under a microscope, and their nano-size networks have mechanical properties. Would an object with strong mechanical properties have more compression than an object with weak mechanical properties? (Answer: The object with strong mechanical properties will be able to resist compression because the strong network remains intact.)

- Can a nanocomposite be compressed and then go back to its original shape? If so, what is type of composite can do this? (Answer: A composite that is elastic can go back to its original shape after it is compressed.)

- Would a soft or hard nanocomposite undergo more strain after compression? (Answer: The softer object because it would have the greatest change in length after compression.)

Safety Issues

- Be careful not to touch the gears while the compressor and MINDSTORMS program are running.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are introduced to the concepts of stress and strain with examples that illustrate the characteristics and importance of these forces in our everyday lives. They explore the factors that affect stress, why engineers need to know about it, and the ways engineers describe the strength of mater...

Students learn about electric motors and rotational sensors. They learn that motors convert electrical energy to mechanical energy and typically include rotational sensors to enable distance measuring. Students create a basic program using the LEGO® MINDSTORMS® interface to control a motor to move a...

References

Hewitt, Paul G. Conceptual Physics. Saddle River, NJ: Prentice Hall, 2002.

Zitzewitz, Paul. Physics Principles and Problems. Columbus, OH: McGraw-Hill, 2002.

Copyright

© 2013 by Regents of the University of Colorado; original © 2010 Polytechnic Institute of New York UniversityContributors

Jennifer S. HaghpanahSupporting Program

AMPS GK-12 Program, Polytechnic Institute of New York UniversityAcknowledgements

Ackn sb: This activity was developed by the Applying Mechatronics to Promote Science (AMPS) Program funded by National Science Foundation GK-12 grant no. 0741714. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: March 2, 2018

User Comments & Tips