Quick Look

Grade Level: 4 (3-5)

Time Required: 45 minutes

Expendable Cost/Group: US $1.50

Group Size: 4

Activity Dependency: None

Subject Areas: Chemistry, Physical Science, Science and Technology

NGSS Performance Expectations:

| 3-5-ETS1-2 |

| 5-PS1-3 |

| MS-ETS1-3 |

Summary

After a brief history of plastics, students look more closely as some examples from the abundant types of plastics found in our day-to-day lives. They are introduced to the mechanical properties of plastics, including their stress-strain relationships, which determine their suitability for different industrial and product applications. These physical properties enable plastics to be fabricated into a wide range of products. Students learn about the different roles that plastics play in our lives, Young's modulus, and the effects that plastics have on our environment. Then students act as industrial engineers, conducting tests to compare different plastics and performing a cost-benefit analysis to determine which are the most cost-effective for a given application, based on their costs and measured physical properties.

Engineering Connection

The development of plastics has had a great influence on our daily lives, more than any other synthetic compound. Plastics have many physical properties that are far superior to traditional materials. For example plastic is able to keep liquids cold longer than glass, while being less breakable and lighter. Plastics are used in an overwhelming number of engineered designs from aircraft to automobiles to soda bottles with screw-on caps. To perform all these different roles, the unique physical properties of plastics are exploited. To design new plastic materials, engineers consider the stress and strain characteristics of various plastic formulations. Students gain an awareness of the prevalence of plastics in their everyday lives and learn about how the unique stress/strain relationships factor into materials choices made by engineers.

Learning Objectives

After this activity, students should be able to:

- Explain that different plastics have unique physical properties.

- Apply stress and strain to test the elasticity of various materials.

- Identify several limitations to the use of plastics on the material and ecological levels.

- Based on the physical properties and cost, determine which plastics are the most cost-effective for unique applications.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-2. Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Generate and compare multiple solutions to a problem based on how well they meet the criteria and constraints of the design problem. Alignment agreement: | Research on a problem should be carried out before beginning to design a solution. Testing a solution involves investigating how well it performs under a range of likely conditions. Alignment agreement: At whatever stage, communicating with peers about proposed solutions is an important part of the design process, and shared ideas can lead to improved designs.Alignment agreement: | Engineers improve existing technologies or develop new ones to increase their benefits, to decrease known risks, and to meet societal demands. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

5-PS1-3. Make observations and measurements to identify materials based on their properties. (Grade 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Make observations and measurements to produce data to serve as the basis for evidence for an explanation of a phenomenon. Alignment agreement: | Measurements of a variety of properties can be used to identify materials. (Boundary: At this grade level, mass and weight are not distinguished, and no attempt is made to define the unseen particles or explain the atomic-scale mechanism of evaporation and condensation.) Alignment agreement: | Standard units are used to measure and describe physical quantities such as weight, time, temperature, and volume. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-3. Analyze data from tests to determine similarities and differences among several design solutions to identify the best characteristics of each that can be combined into a new solution to better meet the criteria for success. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Analyze and interpret data to determine similarities and differences in findings. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: Sometimes parts of different solutions can be combined to create a solution that is better than any of its predecessors.Alignment agreement: Although one design may not perform the best across all tests, identifying the characteristics of the design that performed the best in each test can provide useful information for the redesign process—that is, some of the characteristics may be incorporated into the new design.Alignment agreement: | |

Common Core State Standards - Math

-

Measure the length of an object by selecting and using appropriate tools such as rulers, yardsticks, meter sticks, and measuring tapes.

(Grade

2)

More Details

Do you agree with this alignment?

-

Represent and interpret data.

(Grade

3)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

New York - Math

-

Measure the length of an object by selecting and using appropriate tools such as rulers, yardsticks, meter sticks, and measuring tapes.

(Grade

2)

More Details

Do you agree with this alignment?

-

Represent and interpret data.

(Grade

3)

More Details

Do you agree with this alignment?

New York - Science

-

Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Make observations and measurements to identify materials based on their properties.

(Grade

5)

More Details

Do you agree with this alignment?

-

Analyze data from tests to determine similarities and differences among several design solutions to identify the best characteristics of each that can be combined into a new solution to better meet the criteria for success.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- piece of plastic from a dry cleaning bag, ~30 x 30 cm (~12 x 12 in), labeled A

- piece of plastic from a grocery store bag, ~30 x 30 cm (~12 x 12 in), labeled B

- piece of plastic from a department store bag, ~30 x 30 cm (~12 x 12 in), labeled C

- piece of plastics from a plastic milk container, ~30 x 30 cm (~12 x 12 in), labeled D

- plastic medical examiner glove, labeled E

- Data Collection Sheet, one per person

- pencil

- ruler

Note: The plastic piece sizes are approximate.

To share with the entire class:

- colored tape

- a few different sized notebooks

- a set of the five plastic test pieces (A-E), for a teacher stretch demo

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/nyu_plastic_activity1] to print or download.Introduction/Motivation

From a historical perspective, human eras are often defined by the material that is commonly used to make tools during a time period, for example, the Stone Age, Bronze Age and Iron Age. Given how thoroughly humans have incorporated plastics into their lives during the past 100 years, maybe we should call the current human era the Plastics Age?! (Or, since plastics are generally made from petroleum, maybe the Oil Age?!)

Plastics are used for all sorts of purposes in our daily lives; from the housing of our alarm clocks and remote control devices to the containers that hold our milk and orange juice to the seats in our buses and cars. What are some examples of plastic that you use every day? (Listen to student ideas.)

Why are plastics used so much? From an engineering point-of-view, why are they often the material of choice? Often, plastics are less expensive to manufacture and more durable to use than other more traditional materials like wood, stone, leather, ceramic, glass and metal. The benefits of low-cost plastic are obvious. As an example, in our own kitchens as well as in drought-stricken rural parts of the world, plastic containers have replaced traditional heavy stone and clay containers, reducing the burden of liquid and water transport because they are lightweight, able to hold water without leaking, and tough.

Commercial plastics play a big role in our economy; in 2012 the U.S. plastic industry accounted for more than $373 billion of production. Most of these plastics were fabricated for packing materials including bubble wrap, packing peanuts and water bottles.

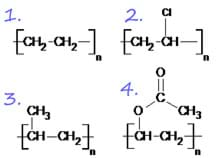

Chemical engineers design plastics. The primary ingredients in plastics are polymers, a substance consisting of repeating molecules, in which each individual molecule is called a monomer. As an analogy, think of a string of pearls as a polymer and the individual pearls as the monomeric subunits, or monomers. Monomers are often composed of similar atoms, such as carbon (C), hydrogen (H), oxygen (O) and chlorine (Cl). Plastics are made of repeating groups of simple structures (see Figure 1) and the simple structures of each plastic have different characteristics. (Even though students won't entirely understand them, consider showing them the molecular structures to hint at what they might see in future chemistry classes.)

Generally, plastic bags are composed of polyethylene (PE). Worldwide, an estimated 80 million metric tons are produced each year, making polyethylene, by far, the most commonly produced plastic. PE comes in a variety of different types; the most common are high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE are used to make the kind of shopping bags you get from department stores, and LDPEs are used for low-grade plastics, such dry cleaning bags. Plastic bags that are typically obtained at grocery stores are generally a blend between the two types.

Have you noticed that all plastic bags are not alike? (Pause to see if any students have comments on this statement.) The molecular composition and geometry of the individual monomers impart unique mechanical properties to individual plastics.

One important parameter that engineers use to investigate materials is the Young's modulus. The Young's modulus is a measure of a material's stiffness. The Young's modulus is determined by a stress-strain test, in which the stress is the amount of force applied per unit area and the strain is the measure of how much the object is stretched or deformed.

In today's activity, we will test how different plastics respond to a stretching force. The elasticity of each type of plastic is a physical property of the material. In engineering, we also refer to this as a "mechanical property." If we are working as engineers and want use that plastic material to make a bag, such as a shopping bag, we want to see how that bag functions when a force such as weight is applied (for example, when we've added heavy groceries to the bag). We would want to measure how much the bag stretches or if it would rip, which are mechanical properties of the bag's plastic material.

In this activity, you will investigate the mechanical properties of different plastics and learn how engineers use their knowledge of these characteristics to select the best plastics to accomplish certain tasks.

Procedure

Background

In general, mechanical properties and physical properties are not necessarily the exact same thing. In the context of this activity, though, the property students are testing (essentially elasticity or deformation under a force [or load]) is a mechanical property and a physical property. When we think of mechanical properties, it is usually related to the real-world functioning of the material. So elasticity is a physical property, but in the context of a material that may need to bear weight and its shape might deform while bearing that weight, we think of its elasticity as a mechanical property.

Before the Activity

- Gather materials and make copies of the Data Collection Sheet, one per student.

- Also prepare an extra set of the five plastic types for the teacher's stretching demonstration.

- If enough materials, consider providing enough plastic test samples so that each student can conduct the experiment.

With the Students

- Present the class with the Introduction/Motivation content.

- Divide the class into groups of three to four students each.

- Discuss with students the different types of plastics and their real-world applications: We know that plastics are used for many different purposes. Who can name a few types of applications? (Possible answers: Milk and juice containers, clothing, shopping bags, bubble wrap, computers, wire coating, all sorts of gadgets and medical devices.) What are the physical differences between these different types of plastics? (Review these key points: Plastics are composed of different monomers and these monomers yield different physical properties in the end products). These materials are constructed for their end functions, for instance a juice container is designed to hold liquids, while a grocery bag is designed to carry food items. What are the physical differences between these materials? Which material is more flexible and which is more rigid? How does that physical property play a role in its end function?

- Show students examples of the five different test plastics. Ask the pre-activity questions described in the Assessment section. Tally student predictions on the board.

- Distribute the sample plastics and data collection sheets. Give each student a data collection sheet and each group five different plastic types, one of each.

- Working in groups, have students observe and discuss the physical characteristics of each test plastic.

These plastics all have different physical/mechanical properties. - Explain to students: Some plastics are elastic, which means that after stretching, they retain their original shapes, similar to rubber bands. Other plastics are inelastic and upon stretching, the plastic becomes permanently deformed. Ask students: Are plastics more useful to us if they retain their original shapes or if they become permanently deformed? (Listen to student responses. Guide students to the realization that plastics can be used over and over if they are able to retain their original shapes. Many plastics that become stretched out or permanently deformed are no longer useful and are thrown away.)

- Establish an objective for the activity: Your challenge is to rank all the plastic materials based on how well they retain their shapes through your testing. Rank the plastics that retain their shapes the best after you stretch them as the best performers. Rank the plastics whose shapes change the most permanently as the worst performers.

- Demonstrate to students how to stretch the plastics. It is important to pull the plastic in a controlled manner. Holding a plastic piece lengthwise, use a high amount of force to stretch the plastic for 3 seconds, but no longer. Stretch each plastic type in front of students in order to show them the difference in elasticity before they are permitted to carry out the activity.

- Direct students to begin the experiment by measuring the length and width of each plastic sample and recording the starting dimensions on the data collection sheet.

- Before each test, as a class, ask students to predict and rank the outcome of each plastic test. Write their predictions on the board, from best to worst performers.

- Then have students apply force to each plastic sample. For consistency, have groups designate one member to stretch each plastic sample (unless enough materials are provided so that all students can conduct the experiment). As students are performing the stress-strain tests, remind them to pull the plastic in a controlled manner. In terms of elasticity, the provided test plastics are diverse enough that the expected results, conceptually speaking, will be fairly consistent, even with students applying varying amounts of force.

- After stretching, have students re-measure the lengths and widths of the plastic pieces, recording the final dimensions on the data collection sheet. While measurements may vary between different groups or individual students, emphasize the overarching concept of material (or physical) properties (such as elasticity) related to function (that is, high load bearing). (Further address these concepts through the post-activity questions.)

- Direct students to independently answer the four critical thinking questions on the bottom of the first page of the data collection sheet, which are the same as the pre-activity questions. Also have them answer the more involved cost-benefit critical thinking questions on the final page of the data collection sheet.

- Conclude with a class discussion that reviews experimental results, revisits student predictions, reviews the critical thinking questions/answers, and explores how engineers take into consideration the properties of materials, their strengths and weaknesses, pros and cons, when determining what materials make sense to use for certain purposes. See the post-activity questions in the Assessment section.

Vocabulary/Definitions

elasticity: A material's ability to be strained and then recover its size and shape after deformation. For example, a rubber band is very elastic; after being stretched it returns to its original shape.

monomer: A chemical compound that can undergo polymerization; a building block of plastics.

polymer: A chemical compound or mixture formed by polymerization, essentially repeating subunits.

strain: A measure of how much a material is stretched when a pulling force is applied to it.

stress: The force applied over a specified area of a material to stretch it.

Young's modulus: The measurement of a material's stiffness. The ratio of linear stress to linear strain.

Assessment

Pre-Activity Assessment

Predictions: Show students the five example plastic types that will be tested in the experiment. Ask students to vote by a show of hands their opinions on the following questions. Tally the votes and write them on the board. Do not give the answers yet; students will discover the answers through experimental testing.

- Which plastic is the strongest? (Answer: In order of strongest to weakest: Plastic milk container, medical examiner glove, department store bag, grocery store bag and dry cleaning bag.)

- Which plastic is the most elastic? (Answer: A medical examiner glove is the most elastic as evidenced by its return to its original shape after repeated stretching.)

- Which plastic would be the best for making a water bottle? Why? (Answer: The plastic milk container is best for making a water bottle since it is not easily deformed, which minimizes the likelihood of liquid spills.)

- Which plastic would be the best for making a sandwich bag? Why? (Answer: The dry cleaning bag is best for making a sandwich bag because it is easy to stretch and break, and thus, easy for anyone to handle and not damaging to the contents.)

Activity Embedded Assessment

Experimental Predictions: Before each test, ask students to predict and rank the outcome of each plastic and write them in hierarchal order on the classroom board, best to worst performers. Best performers are the plastics that retain their shapes under the application of force, and worst performers are those whose shapes change (deform) the most permanently with the application of force.

Answer: Ranking of best to worst performers:

- plastic milk container

- medical examiner glove

- department store bag

- grocery store bag

- dry cleaning bag

Post-Activity Assessment

Engineering: As part of a concluding class discussion, ask students to discuss their opinions and conclusions as you guide the discussion with real-world application questions such as the following:

- How can you relate the strength of a plastic to the contents it carries? (Note: Spur discussion by asking some exaggerated examples such as: Would you carry big rocks in dry cleaning bags? Would you serve or store soup in a glove?)

- If the plastic milk container is the strongest, why don't we use it to carry everything? (Note: Expect students to answer this question in terms of cost, utility [store space requirements and limitations] and ecological impact.)

- With the applied stress (stretching), what changes in strain (change in shape) did you see for each plastic? Based on the data, which plastic is most easily stretched and retains its original shape (which plastic is most elastic)? Which plastic is the stiffest (which plastic has the highest Young's modulus)? (Note: Have students relate their data to their findings and ask them to express their answers with the new vocabulary learned in the activity.)

Data Sheet Questions: Review students' answers to the Data Collection Sheet questions to assess their individual comprehension of the activity concepts, including the cost-benefit analysis.

Safety Issues

Cutting the plastic milk container may leave sharp edges. Run a low-grade piece of sandpaper along the edges to smooth them.

Troubleshooting Tips

Students may find that both the dry cleaning bag and the grocery store plastic bag lose their structural integrity after only a mild force is applied, which generally stems from uncontrolled pulling. Students should not stretch for longer than 3 seconds. It may help to use low-quality or old grocery bags as they are easier to stretch than dry cleaning bags.

Activity Extensions

Ask students to examine the negative aspects of plastics. After assessing the physical properties of these materials, ask students to think of other materials that could be used to perform the same task, for example, brown paper bags instead of plastic sandwich bags. Have students openly discuss the differences between paper and plastic. Include the following topics in discussion:

- How plastics are made (petrochemical raw material), compared to how paper bags are made (wood raw material).

- The physical properties of these materials.

- The degradability of the two different materials and what this means for communities and the environment (long-term consequences).

Activity Scaling

- For lower grades, eliminate the worksheet section that addresses the cost-benefit analysis and instead, go through the topic as a class discussion.

- For upper grades, have groups apply the same testing procedure to additional identified plastic types and investigate how the specific molecular arrangement of the plastic influences the observed physical characteristics.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students explore the chemical identities of polymeric materials frequently used in their everyday lives. They learn how chemical composition affects the physical properties of the materials that they encounter and use frequently, as well as how cross-linking affects the properties of polymeric mater...

Copyright

© 2014 by Regents of the University of Colorado; original © 2011 Polytechnic Institute of New York UniversityContributors

Sharon Holiday, Peter James Baker, Joseph FrezzoSupporting Program

AMPS GK-12 Program, Polytechnic Institute of New York UniversityLast modified: March 13, 2020

User Comments & Tips