Summary

Students learn the concept behind the engineering design of a polymer brush—a coating consisting of polymers that is “tethered” to a particular surface. Polymer brushes can be used on water filtration membranes as an antifouling coating. After designing a model that represents an antifouling polymer brush coating for a water filtration surface, students take on the challenge to engineer their brush design on the surface of a Styrofoam block (which serves as a model for a surface filter) using various materials.Engineering Connection

Engineers who work in fields such as plastics, chemistry, physics, and biology often work together to develop sustainable solutions for the environment; in particular, water quality. For example, engineers may be tasked with the design of coatings that control interactions between a surface and an environment. These designs are called antifouling coatings which are used in a range of applications, from medical devices and biological implants to wastewater plants and shipping hulls. In this activity, students learn how to make an antifouling coating for a model water filtration membrane. Students employ the engineering design process as they attempt to develop a brush filter system to prevent fouling. Each group will be provided opportunities to test their design and then make improvements based on its performance.

Learning Objectives

After this activity, students should be able to:

- Predict how changing a component of their design might improve or impair its properties.

- Explain the thinking behind their engineered solutions.

- Test the design for functionality.

- Collaborate in groups to create the best design from a collection of individual designs or features.

- Examine the successes and shortcomings of a design and further iterate upon it.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: | Models of all kinds are important for testing solutions. Alignment agreement: The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the relationships among technologies and the connections between technology and other fields of study.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to assess the impact of products and systems.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

Texas - Science

-

plan and implement comparative and descriptive investigations by making observations, asking well-defined questions, and using appropriate equipment and technology;

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

identify advantages and limitations of models such as size, scale, properties, and materials; and

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

recognize human dependence on ocean systems and explain how human activities such as runoff, artificial reefs, or use of resources have modified these systems.

(Grade

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- Styrofoam block, approximately 17 cm x 30 cm (6.6 inch x 11.8)

- 20 pipe cleaners

- 40-50 small pom-pom balls, 1.3 cm (0.5 in)

- 10 large pom-pom balls, 5 cm (2.0 inch)

- 10 rubber bands

- yarn, 2 m (6.5 ft or more)

- aluminum foil, 50 cm x 27 cm (19 in. x 11 in.)

- masking tape, 1 roll

- container or tray to hold and organize group materials

- scissors

- cups (for holding a volume of pom-poms that will be “spilled” on to their designs) 0.5 L (18 oz.)

- Designing Polymers to Clean Water Worksheet (one per student)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/rice2-2347-polymers-clean-water-design-activity] to print or download.Introduction/Motivation

(Introduce the Designing Polymers to Clean Water PowerPoint Presentation to the class.)

Let’s start our activity out with a simple question: what does dirty water look like? Think about a pond, a lake, a river, or even an aquarium. What might form on the surface of a pond or lake, or what might collect at the edges of a river? How do we know a filter may not be working in an aquarium? Let’s examine Figure 1 as an example below and then answer the following questions.

- What do you think about this water? (Possible answers: It’s dirty; it’s cloudy; it looks unhealthy.)

- Why do you consider this water as “dirty”? (Possible answers: It doesn’t look clear; it looks like it has a buildup of something on the inside; it looks like it has been sitting, or stagnant, for a while.)

- How can we make this water “clean”? (Possible answers: we could replace it; we could check the filter and replace it.)

Filters are used to purify water from a variety of sources, including freshwater lakes, rivers, and underground wells. Engineers can even build highly complex filters called to remove the salt from ocean water! However, for common household use, filters are commonly used to purify water sources including tap water and collected rainwater. Filters are also important for use in water filtration applications in developing countries where clean water may be scarcer. However, filters come with their own set of problems.

Using a filter means putting it through several stages. A brand-new filter out of the box is highly effective and maintains its properties even after extensive use. However, if a filter is designed effectively, it will eventually become covered with foulants. A foulant is an unwanted substance that adheres to a particular surface. (See an example of a used filter on Slide 12 of the Designing Polymers to Clean Water PowerPoint Presentation.)

Foulants can be inorganic or organic in nature. Rust, lime build-up, or corrosion are all examples of inorganic fouling. Organic fouling could consist of algae, plant matter, or even bacteria. Foulants can cause the purification process to be inefficient, lower water quality, and waste energy of the filtration system.

Today you are playing the role of engineers! Your goal: to create a solution that could extend the life and quality of water filtration systems using only available materials. Your invention could be especially important in countries where clean drinking water is hard to find! You will design a model for adding an antifouling surface to a water filtration system.

Procedure

Background

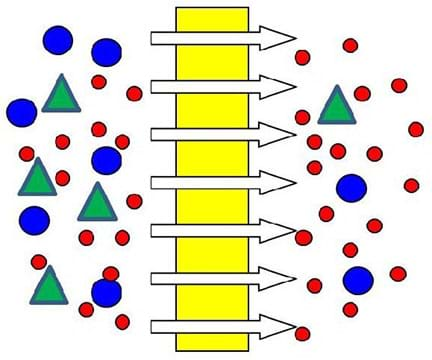

Fouling is when an undesired layer of substances adhere to the surface of a water treatment membrane. In this case, foulants adhere to a water filtration membrane over time of normal use. Fouling is troublesome because it can degrade water quality and make the water filtration process inefficient. All water filtration membranes, the semi-permeable surface where the filtration occurs, are prone to fouling. Finding a way to extend the life of an existing membrane to prevent or resist fouling is important. One such engineering application is in the form of polymer brushes, which are dense layers of polymers attached to a surface. These brush-like polymers have the potential to function as water filtration coating that is also fouling resistant. The polymers have hydrophilic (water-attracting) interactions that serve to form a hydration layer that repels foulants. This hydration layer provides a “self-cleaning” effect on the filter.

Engineering technologies such as polymer brushes can have a wide reaching effect, Because obtaining fresh, clean water can be very difficult in many places around the world, this activity can be used as a model to help the students begin to think of the process of modifying a surface to obtain a more desired outcome, which is a basic goal of the antifouling polymers research and design.

Before the Activity

- Before beginning the activity with the students, collect an appropriate amount of materials and place them in stations around the room, either in a container or on a tray where they will have easy access to the materials in one place.

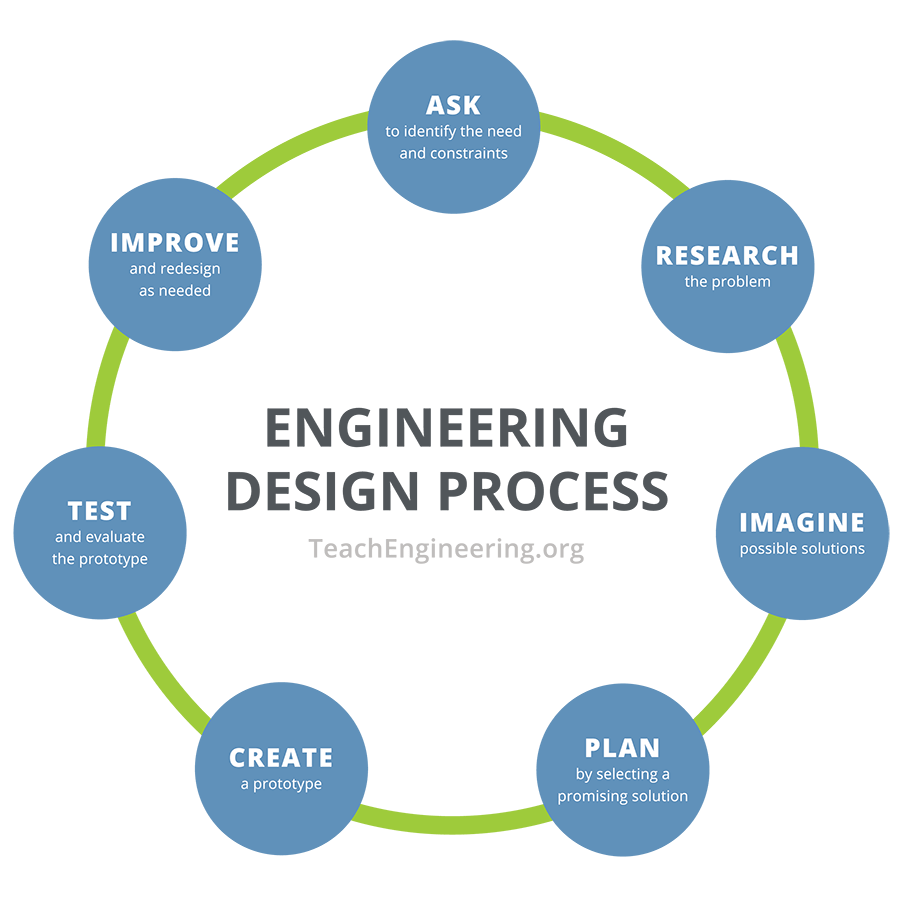

- Review the activity vocabulary and the Designing Polymers to Clean Water PowerPoint Presentation. Also, talk students through the engineering design process and pay particular attention to the iterative nature of the process (see Figure 2 below):

With the Students

- Display the Introduction along with the Designing Polymers to Clean Water PowerPoint Presentation. This will introduce the concept of fouling and the design challenge.

- Using the Engineering Design Process as a reference (see Figure 2), instruct students on how they will use the process to develop a model, or prototype, to solve the problem of fouling by creating an antifouling water filtration membrane coating, using the materials available at their table.

- Distribute copies of the Designing Polymers to Clean Water Worksheet. Have students complete Questions 1 and 2.

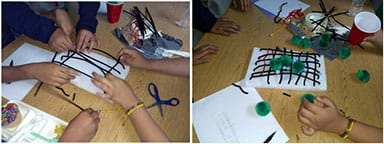

- Distribute one Styrofoam block per group (this serves as the model of the surface for their water filtration system membrane). Explain that their goal is to make a system that modifies the surface of their water filtration “membrane.” The system should be a design that allows water molecules (small pom-poms) to interact with the membrane (the Styrofoam block), but keep the foulants (the large pom-poms) from interacting with the membrane.

- Tell group to use the following materials: pipe cleaners (which represent the hydrophilic polymer), yarn, aluminum foil, tape (all different types of side chain possibilities), and scissors.

- Give students several minutes to think about the materials they have, and what they will be able to do with those materials as well as their limitations.

- Tell students to brainstorm individually and to make a blueprint of the materials they will use to create a model of an antifouling coating of a water filtration membrane. After they finish brainstorming, have them share their ideas with their groups. Instruct students to select the best parts of each person’s design to create the prototype for their group, which is step four of the engineering design process.

- Provide approximately five minutes for students to follow these directions using their Designing Polymers to Clean Water Worksheet.

- Have students predict the outcome of what they expect from their blueprint and to outline a system for determining the success of their design. After completing that step, instruct students to build their prototype (step five of the engineering design process) and test it (step six of the engineering design process) to see how well it works. Give students time to test and retest their designs.

- Let students discuss predictions in their groups for five minutes. Then, have them gather materials and build their models for 15 minutes. Finally, have students test their models and redesign their antifouling systems for another five minutes. Students should complete their Designing Polymers to Clean Water Worksheet during this time.

- After students finish testing and redesigning, have each group share their results (see the Design Presentation in the Activity Embedded Assessment below). Conduct the Post-Activity Assessment.

Vocabulary/Definitions

antifouling: Properties that to remove foulants (or adhesion of unwanted substances to a surface).

foulant: Unwanted substances that can adhere to a surface.

hydrophilic polymer: A repeating chemical chain that attracts or is attracted to water.

membrane: The semi-permeable surface where filtration occurs.

polymer: A bonded, repeating series of molecules or structures in a chain.

Assessment

Pre-Activity Assessment

Engage Questions: Students will think, pair and share, answering the following questions.

- What effect do you believe foulants could have on the water filtration membrane (without the polymer brush)? (Example answer: They could cause the filter to clog or not work properly.)

- How could the water be affected? (Example answer: Undesired particles could remain in the water, causing people who drink the water to get sick.)

Activity Embedded Assessment

Worksheet: Students complete the Designing Polymers to Clean Water Worksheet which walks them through the steps of the engineering design in the context of designing an antifouling polymer brush model. It includes opportunities to state the problem, brainstorm solutions, plan a design, test how well it works quantitatively, and improve upon their design and share their results with the rest of the class.

Design Presentation: Students will give a two-minute oral presentation on their design to the class, answering the following questions:

- What would it look like if your membrane was fouled?

- Why did you design it the way you did?

- How well did it work?

Post-Activity Assessment

Revaluation: Ask students the following questions:

- Based on the design that you made, what types of changes could you make to make it work even better?

- What are some potential limitations of the model in comparison to real life?

Investigating Questions

How can we engineer a model for an anti-fouling coating of a water filtration membrane? (Example answers: use the engineering design process to create the model, attach different materials to the pipe cleaners to create hydrophilic polymer chains, etc.)

Troubleshooting Tips

- Make sure that students understand that the water molecules (small pom-poms) should be able to make it through to the membrane, while the foulants need to be kept away from the membrane (Styrofoam board), or ideally even repelled from it.

- Students can cut, rip, or tear any of the materials except for the pom-poms and the membrane (Styrofoam board)

- Make sure the parts of the brainstorming design are labeled so that the students can clearly follow their plans.

Activity Extensions

Students can draw their new and improved design based on their testing and what changes they think they would make their prototype design better. They may also calculate the water flow efficiency and the percentage of foulant blockage (see Designing Polymers to Clean Water Worksheet).

Students may be given the option to bring in their own items to further enhance their designs.

Activity Scaling

- For lower grades, students design a smaller area to cover (size down the Stryofoam block).

- For higher grades, students can consider how they would change the design if the shape of the Styrofoam is different, like the membrane surface is spread over a multidimensional shape.

- Students could use foulants of different sizes and shapes that they have to prevent from getting through to the membrane.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!Copyright

© 2019 by Regents of the University of Colorado; original © 2018 Rice UniversityContributors

Chinyere Enemchukwu; Dr. Rafael Verduzco; Christina Crawford; Dr. Carolyn Nichol ; Hao MeiSupporting Program

Engineering Research Center for Nanotechnology Enabled Water Treatment Systems (NEWT) RET, Rice UniversityAcknowledgements

This curriculum was based upon work supported by the National Science Foundation under Rice University Engineering Research Center for Nanotechnology Enabled Water Treatment Systems (NEWT) RET grant no.1449500. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Special thanks to Dr. Verduzco, Christina Crawford, Dr. Carolyn Nichol and Hao Mei.

Last modified: September 1, 2021

User Comments & Tips