Quick Look

Grade Level: 10 (9-11)

Time Required: 45 minutes

Lesson Dependency: None

Subject Areas: Algebra

NGSS Performance Expectations:

| HS-ETS1-2 |

Summary

Students gain perspective on the intended purpose of hydraulic accumulators and why they might be the next best innovation for hybrid passenger vehicles. They learn about how hydraulic accumulators and hydraulic systems function, specifically how they conserve energy by capturing braking energy usually lost as heat. Students are given the engineering challenge to create small-scale models from which their testing results could be generalized to large-scale latex tubing for a hydraulic accumulator. After watching a video clip of an engineer talking about his lab-based model to test the feasibility of using an elastomer as an energy accumulator, they brainstorm ideas about how latex can be used in a hydraulic system and how they could test the strength of latex for use in a hydraulic accumulator. The concepts of kinetic energy and energy density are briefly discussed.Engineering Connection

Engineers use energy density as a parameter to evaluate the amount of energy stored in a given system. Engineers often experiment and test extensively with small-scale models in order to generate results and generalizations that lead to new designs and final products that are more efficient and more cost effective.

Learning Objectives

After this lesson, students should be able to:

- Explain the need for developing efficient hydraulic accumulators in modern passenger cars.

- Describe the basics of hydraulic accumulators.

- Explain the relationship between strength and pressure in latex tubing.

- Explain how engineers must consider how to design and test models.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This lesson focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Tennessee - Science

-

Investigate kinematics and dynamics.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Pre-Req Knowledge

No specific pre-requisites exist for students, but the teacher should be knowledgeable about hydraulic hybrid vehicles and hydraulic accumulators and as advised to watch the Interview with an Engineer video in advance in order to understand the research project and vocabulary.

Introduction/Motivation

(Be ready to show students two digital videos. Make sure students have paper/journals and pencils handy.)

How many of you know someone who drives a hybrid vehicle? How do hybrid vehicles differ from conventional vehicles? What are some of the major advantages to driving hybrid vehicles? (Give student groups some time for brainstorming as described in the Assessment section. Then listen to student responses. Hybrid vehicles rely on two or more distinct power sources. The intended advantages are fuel savings and emissions reduction. The most common type is a gas-electric hybrid.) Now we are going to look at an important question that engineers are currently investigating in order to make hybrid vehicles even more efficient.

Two different types of hybrid vehicles are available today: hydraulic hybrids and electric hybrids. We will focus on hydraulic hybrids, which use pressurized fluid as a power source. One aspect of the hydraulic system is a hydraulic accumulator. A hydraulic accumulator is a device that is able to store potential energy in the form of pressurized fluid. This is a great device for a hybrid vehicle, because it enables energy to be stored during the braking process and then used to accelerate the car when needed.

Now let's watch a short video made by the U.S. Environmental Protection Agency (EPA) about hydraulic hybrid vehicles to get a little more information about why they are so important. (Show students the 1:20-minute Why Hydraulic Hybrid Vehicles? video. Topics covered: Hydraulic hybrid vehicles [HHVs] are efficient, clean and cost effective due to higher fuel efficiency, fewer emissions and lower costs to manufacture and operate; example HHVs are UPS trucks and Caterpillar excavators.)

As you'll learn in an upcoming interview with an engineer (via a video clip), engineers are currently researching and designing hydraulic accumulators that use materials such as latex tubing. It is extremely important for the latex to be strong enough to not rip or tear.

Now, I'm going to tell you our engineering challenge. After hearing the challenge, get out your journals and write down your initial ideas about how to test the strength of latex tubing.

Engineering challenge: Engineers face many challenges when considering how to design large-scale systems. The current energy accumulator technology can only be employed on heavier trucks. Before making an actual hydraulic accumulator that fits and works in the more commonly used smaller and lighter four-door sedans used by most people, engineers design and test small-scale models. These smaller models are tested in a lab to produce results that lead to the development of actual accumulators that are placed in the newest versions of passenger cars. Your task is to think of how you would create a model that could be generalized to large-scale latex tubing for a hydraulic accumulator.

Think about how you would create an initial design that would provide useful results with limited cost and materials. When you are finished writing down your initial ideas, we will discuss them as a class and pull ideas from each group in order to come up with the best design. (After about 10 minutes, have students share their ideas while you write them on the classroom board, grouping and categorizing them as a class as the ideas come forth.)

Next, let's watch a short video clip from an expert who is working on these exact design challenges in an engineering lab.

(Show students the 9:32-minute Interview with an Engineer video in which an engineering graduate student at Vanderbilt University shows and talks about a lab setup to test how feasible it is to use an elastomer as an energy accumulator. The idea is to try to store the energy usually lost in braking by expanding a rubber balloon [blowing up a thick-walled rubber vessel] to capture the energy and hold it and then release it to move the vehicle. The researchers are trying to design a small-enough and light-enough system that can work in a typical four-door sedan—the type of vehicle used by so many people, which would multiply the fuel savings by a great amount of people. It is helpful for students' comprehension of this lesson that they become familiar with the video clip and its use of advanced vocabulary terms. Be prepared to pause the video numerous times to explain certain aspects of the design, and answer and ask questions to keep students focused. When the video is over, have students write in their journals again about how they would design a model now that they have seen an actual model being used and tested.)

Now, write down in your journals your new ideas after watching the video. How are you going to test the amount of energy needed to make a car move after releasing the brakes? What variables might you need to consider in order to demonstrate that your model is efficient?

Lesson Background and Concepts for Teachers

About the Lesson : This student-driven lesson is primarily discussion-based; its activity component is student involvement in brainstorming, writing and discussion. Once the challenge is explained, the main thrust of this lesson is for students to brainstorms ideas themselves and then in their groups. Once students have watched the Interview with an Engineer and finished writing in their journals, have them work in small groups to brainstorm ideas about how latex can be used in the hydraulic accumulator and how it can be tested for strength. Expect the engineer interview video to provide students with enough information to figure out how to get started. Throughout, challenge and encourage students to express their ideas clearly.

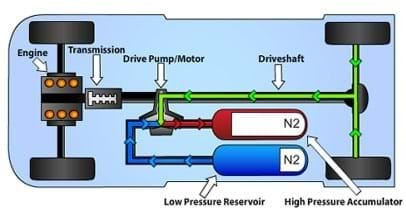

About HHVs : Hydraulic hybrid vehicles (HHVs) use a regular combustion engine and a hydraulic system. The hydraulic system includes hydraulic accumulators, which store pressurized fluid, and a hydraulic drive pump or motor. When a HHV brakes, energy is stored in the form of pressurized fluid, which then can be used to rotate the wheels when the vehicle is accelerating. This process is referred to as regenerative braking because it converts kinetic energy to potential energy, which is then reconverted to kinetic energy. In regenerative braking, the drive pump/motor in the hydraulic system uses kinetic energy from the wheels to pump fluid to a high-pressure accumulator. The energy is stored as potential energy, and the brakes do not experience as much friction while stopping the vehicle as an equivalent vehicle without a hydraulic system. If the vehicle accelerates lightly, the drive pump/motor uses the energy stored in the hydraulic accumulator to power the driveshaft. If more acceleration is necessary, the vehicle's engine also provides power to the wheels. When the vehicle is cruising, the engine supplies full power.

The hydraulic system in a HHV is energy efficient because it captures most of the energy that is usually lost as heat in conventional vehicle braking systems, increasing the energy density of the vehicle. The U.S. Environmental Protection Agency (EPA) has been a leading supporter of hydraulic hybrid research and development. An example of a hydraulic hybrid regenerative braking system is Hydraulic Launch Assist (HLA), which was produced by the Eaton Corporation and has been used and tested by the Ford Motor Company. Goals for hydraulic hybrid vehicles include achieving higher fuel economy, reducing vehicle emissions and maintaining or even improving vehicle acceleration performance. See the Additional Multimedia Support and References sections for resources for further research on the topic.

Example HHVs: Vehicles that operate in a lot of stop-and-go traffic are ideal for hydraulic hybrid systems. For example, United Parcel Service (UPS) hydraulic hybrid delivery trucks use energy efficiently and produce less pollution than conventional cars. Excavators are another example; they are big and heavy earth-moving construction equipment with arms that stop and go all day, presenting a good opportunity to conserve energy. When an excavator arm swings between two points, it must break at each point, resulting in lost energy. With Caterpillar's new hydraulic hybrid excavator, the braking energy is not lost. Instead, it is stored as pressure in an accumulator and then that pressure is used to help the machine swing its arm.

Lesson Closure

We've had a lot of time in today's class to brainstorm ideas, both individually and in small groups. Now let's come together as a class and share our thoughts. Remember, engineers work together in many different-sized teams and they share ideas with each other so that their designs are well thought out and informed. By sharing our ideas, we can work together to create the best solution possible. Make sure that the ideas you share are clear and concise before presenting them to the class.

(On the classroom board, write and categorize student ideas. Have each group share its ideas, and list them in suitable categories. Have students assist in determining what categories are necessary, based on the ideas shared.)

Great! Now we have a good list of ideas. Make sure to copy and save this list because you will need it to create a labeled design for your homework.

Vocabulary/Definitions

energy density : The quantity of energy stored in a system or given space per unit volume.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. The main steps of the design process: ask: identify the need and constraints; research the problem; imagine: develop possible solutions; plan: select a promising solution; create: build a prototype; test and evaluate prototype; improve: redesign as needed.

generalization : An extension of initial ideas and designs, usually the result of testing models in order to create final designs.

kinetic energy : The energy of motion. The amount of work needed to accelerate an object of a given mass from rest to its current velocity.

model: A drawing, description or physical object that is used to make sense of and explore a subject matter or idea. For engineers, models are essential to the overall design process; they assist in creating even better designs that lead to final products.

potential energy: Stored energy. An object's amount of potential energy is based on its position and the forces acting on it.

Assessment

Pre-Lesson Assessment

Brainstorming: Ascertain students' knowledge and raise real-world interest about the topic. Ask students the following questions and have them engage in open discussion within small groups. Remind them that brainstorming is the time to be very creative. During brainstorming, no idea or suggestion is "wrong or ridiculous." Respectfully listen to all ideas. Ask the students:

- How might hybrid cars be less damaging to the environment than conventional cars?

- How do hybrid cars work?

- How might engineers test to see if the mechanisms of a hybrid car work?

- Are there different types of hybrid cars?

- What might latex have to do with hybrid cars?

Post-Introduction Assesment

Journal Writing: After first hearing the challenge and again after watching the Interview with an Engineer, have students document in their journals their ideas on how they would create an initial design for a limited cost and materials model from which its useful testing results could be generalized to large-scale latex tubing for a hydraulic accumulator. This journal writing gives students a chance to brainstorm and develop their ideas individually, before sharing their thoughts with a group. While students are writing in their journals, circulate to answer any questions and make sure all students are on task.

Homework

Reflection & Design: After class discussions, assign students to go home and reflect on all the ideas discussed and generated in class, thinking independently about how they would best design experimental models that would allow them to generalize to large latex use. Require them to create labeled drawings of their designs to turn in the next day.

Additional Multimedia Support

Why Hydraulic Hybrid Vehicles? (1:20 minutes) U.S. Environmental Protection Agency (EPA) video: https://www.youtube.com/watch?v=sRkvGEN7ySE

How Parallel Hydraulic Hybrid Vehicles Work (regenerative braking, light acceleration, extended acceleration, cruising, including mechanical diagrams), U.S. EPA http://www.epa.gov/otaq/technology/research/how-it-works-parallel.htm

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Student groups act as engineering teams by conducting experiments to collect data and model the relationship between the wall thickness of the latex tubes and their corresponding strength under pressure (to the point of explosion). Students learn to graph variables with linear relationships and use ...

Students use latex tubes and bicycle pumps to conduct experiments to gather data about the relationship between latex strength and air pressure. Then they use this data to extrapolate latex strength to the size of latex tubing that would be needed in modern passenger sedans to serve as hybrid vehicl...

Students learn about the fundamental concepts important to fluid power, which includes both pneumatic (gas) and hydraulic (liquid) systems.

References

Deaton, Jamie Page. How Hydraulic Hybrids Work. How Stuff Works. Accessed 2010. (animated diagrams of parallel and series hydraulic hybrid mechanics as trucks stop and go) http://auto.howstuffworks.com/hydraulic-hybrid.htm

High Energy-Density Hydraulic Accumulator. Center for Technology Transfer & Commercialization, Vanderbilt University (summary, description, current status) http://www.vanderbilt.edu/cttc/technology/high-energy-density-hydraulic-accumulator

Hydraulic Hybrid Research (What are HHVs? Why are HHVs So Efficient?). Clean Automotive Technology, U.S. Environmental Protection Agency. Accessed 2010. http://www.epa.gov/otaq/technology/research/research-hhvs.htm

Hydraulic Hybrid Technology—A Proven Approach. Written March 2004. Clean Automotive Technology... Innovation that Works, U.S. Environmental Protection Agency, EPA420-F-04-024. Accessed 2010. http://www.epa.gov/oms/technology/420f04024.pdf

Kratochwill, Lindsey. Why Hydraulic Beats Electric. Posted February 11, 2013. Fast Company magazine. March 2013, issue 173, pg. 28. Accessed December 4, 2013. http://www.fastcompany.com/3005158/caterpillars-new-hybrid-excavator-hydraulic-beats-electric

Presher, Al. Hybrids in Motion. Posted June 15, 2009. Automation & Control, DesignNews. Accessed 2010. http://www.designnews.com/document.asp?doc_id=228470

Presher, Al. Hydraulic Hybrid Trucks Hit the Road. Posted December 7, 2011. Automation & Control, DesignNews. Accessed 2010. http://www.designnews.com/document.asp?doc_id=236226

Wiebusch, Bruce. Hydraulic Regenerative Braking Improves Large-Truck Fuel Economy. Posted June 17, 2002. Automation & Control, DesignNews. Accessed 2010. http://www.designnews.com/document.asp?doc_id=214915

Copyright

© 2013 by Regents of the University of Colorado; original © 2006 Vanderbilt UniversityContributors

Erik Bowen, Carleigh SamsonSupporting Program

VU Bioengineering RET Program, School of Engineering, Vanderbilt UniversityAcknowledgements

The contents of this digital library curriculum were developed under National Science Foundation RET grant nos. 0338092 and 0742871. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: September 13, 2020

User Comments & Tips