Summary

In this design activity, students investigate materials engineering as it applies to weather and clothing. Teams design and analyze different combinations of materials for effectiveness in specific weather conditions. Analysis includes simulation of temperature, wind and wetness elements, as well as the functionality and durability of final prototypes.Engineering Connection

Engineers have the important job of designing materials for clothes so they meet specific weather conditions. For example, in 1976, Robert Gore created Gore-Tex fabrics, which are now widely known for their applicability for outdoor activity clothing. Gore-Tex offers protection from wind and rain, but is breathable at the same time, allowing sweat to escape via evaporation. Materials engineers also develop textiles that resist wrinkles, stains, odors, are more durable, incorporporate electronics, and are suited to a human health and safety on Earth and in space.

Learning Objectives

After this activity, students should be able to:

- Explain the importance of materials engineering for survival and comfort in various weather conditions.

- Describe several examples of engineered materials and textiles.

- Model and analyze different materials for the effectiveness to resist wind, water and cold temperatures.

- Describe and understand the steps of the engineering design process.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Refine design solutions to address criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Colorado - Science

-

Differentiate between basic and severe weather conditions, and develop an appropriate action plan for personal safety and the safety of others

(Grade

8)

More Details

Do you agree with this alignment?

-

Examine, evaluate, and question information from a variety of sources and media to investigate how climates vary from one location to another on Earth

(Grade

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- thermometer

- scissors

- Materials Analysis Worksheet, one per person

To share with the entire class:

- a variety of cloth scraps, such as felt, cotton, fleece, polyester, etc.

- a variety of other materials, such as aluminum foil, plastic wrap, brown paper, shower curtain liner, etc.

- needle and thread

- duct or masking tape

- 1 or more fans, as a source of wind

- 1 or more spray bottles filled with water

- 1 or more containers of ice

- (optional) water repellent spray

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_weather_lesson01_activity1] to print or download.Introduction/Motivation

The way you dress always impacts your comfort, but during extreme weather conditions it can be important to your survival. People sometimes think that fashion designers are the only ones who participate in designing clothes, but in reality, many engineers are at the forefront of designing new fabrics and clothing materials for every weather condition — from sweltering hot to freezing cold and everything in between. These engineers must take cost, comfort, durability and much more into account for the success of their designs.

Clothing has always had the main purpose of providing protection and comfort from heat or cold. Once those two things are achieved, engineers asked the question, "What's next?" The study of materials engineering has led to research and development of textiles (cloth) that resist stains, repel water, resist wrinkles, or last longer. Though some of these fabrics look just like they did before, they might contain tiny fibers or a special coating that gives them new properties. Some textiles are blended with fibers of silver, gold and polymers to improve their durability and functionality. Other fibers are coated to help them become water resistant.

Even more advancements have been made in textiles besides the addition of fibers or coatings. Electronic textiles incorporate circuits into the fibers of the cloth. The uses for this cloth are endless, from material that changes color under electronic control to clothing that integrates electronics such as MP3 players. In fact, one example of this is a jacket made by Burton Snowboards, in which the fabric allows control of an MP3 player by pressing a keypad on the sleeve.

Other examples of engineered textiles include materials for space suits or spacecraft landing, clothing that monitors your heart rate for medical reasons, and shoes that adjust their support based on whether you are walking or running.

Engineers are always asking the question, "What's next?" in their designs. When it comes to improving textiles and materials for the health and safety of people, they use their knowledge of weather, electronics and the natural world to create clothing that can benefit and even save the life of the wearer.

Today, we are going to be materials engineers that analyze the properties of available materials for an extreme weather condition. Think about how the materials you analyze could be blended or combined to create clothing to keep people safe and comfortable. Ask yourself, "What's next?" The possibilities are endless.

Procedure

Background

Dark-colored clothing absorbs heat and is suited to cold environments. Light-colored clothing reflects heat and is great for hot climates. Cotton "breathes," while leather does not. Layers of clothing are the best protection from the extreme cold.

Before the Activity

- Gather materials. Place different types of fabric, aluminum foil, plastic, etc., at a Materials Station for students to choose from for "blending" or layering of material to create a new material prototype. Water repellent spray can be used as a coating form of material modification.

- Make copies of the Materials Analysis Worksheet.

- Develop a Testing Station in the classroom. This station should include a fan (wind), spray bottle (water/snow) and a container of ice to demonstrate cold temperatures.

With the Students

- Give students the following scenario: Today, you are engineers using the engineering design process to design a new layered material that can endure the harsh conditions of a blizzard, including high winds, wet snow and cold temperatures. You will work in teams to analyze several different existing materials in order to design a new layered material. Your task is to develop a design that combines one or more of the materials that you have tested. After you have developed a prototype (model) of this new layered material, you will conduct analysis at a testing station to determine how well the material holds up during wind, wet snow and cold.

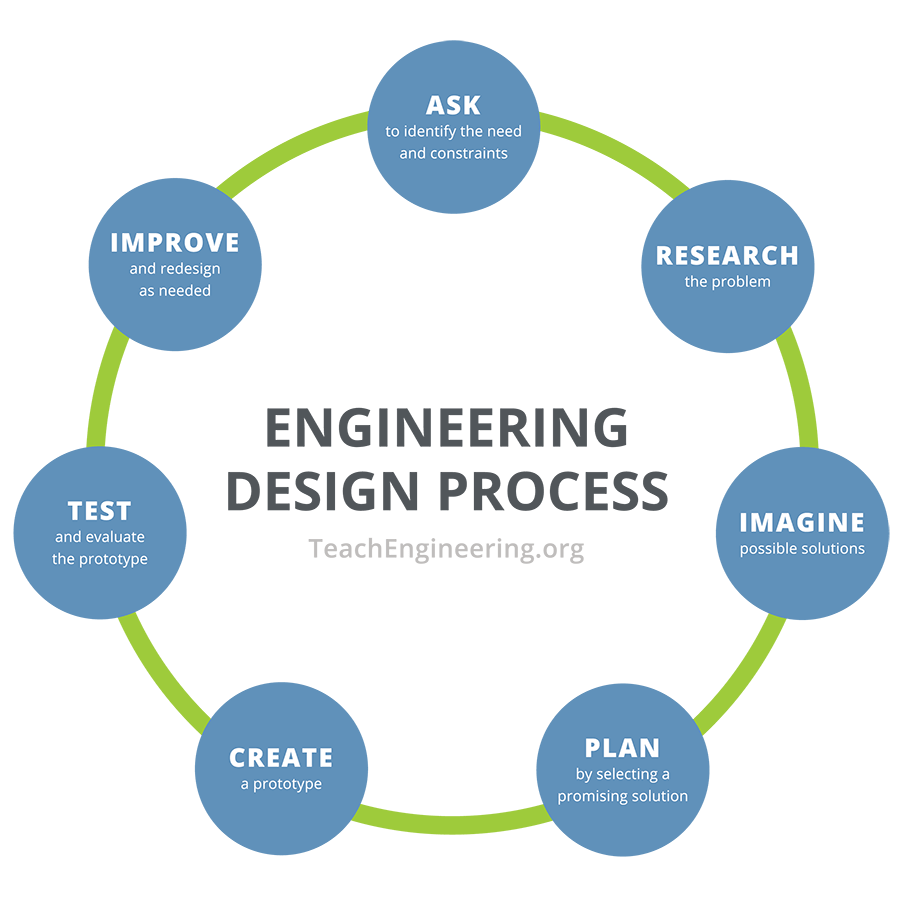

- Ask if any of the students have heard of the engineering design process (EDP) before? (Elicit student answers). Explain that engineers around the world use the engineering design process to solve problems. Either display the graphic below on a projector or draw the seven steps on the board so the students can see what the process involves.

- Have students develop a problem statement for their design that includes the type of weather they are designing for (in this case, a blizzard) as well as criteria and constraints they need to adhere to. Remind them that identifying the criteria and constraints is part of the first step of the engineering design process (ask).

- Have students imagine different solutions on how they should test the different materials for resistance to wind, snow and cold temperatures. Have them describe their processes on their worksheets.

- Next, have students choose up to five materials to analyze.

- Have students complete their materials analyses, following the worksheet. For the analysis, wind is provided by the fan, water from snow by the spray bottle, and cold temperature by the container of ice.

- Next, have students choose which of their tested materials they want to use in their new material designs and explain why they are choosing those materials. (What makes these materials good for blizzard weather conditions?)

- Have students imagine and sketch out designs using their chosen materials. Encourage student teams to share their different designs and have them move into the fourth step of the EDP (plan) by selecting the most promising solution. Have them draw designs of their new materials and how the individual pieces will be layered. Approve student designs before they begin creating their prototypes. Ask students about their thinking in formulating their designs. Why do you think this will work? Do you think it would be comfortable? Would you want to wear it? Why or why not?

- Give students time complete step 5 and 6 of the engineering design process and create and test their new material using the provided materials.

- Have students complete their worksheets, analyzing how well their new materials functioned, what changes they would make, and how they could be used during blizzard conditions.

- Have teams present their creations to the class and explain their reasoning for their new materials and the processes used to test them. What do you think that blizzard weather would be like? How well would your new material work in those conditions? How would you market this material to a community who might experience a blizzard?

Vocabulary/Definitions

extreme weather: Severe or unseasonable weather phenomena.

Assessment

Pre-Activity Assessment

Discussion/Brainstorming: As a class, have students engage in open discussion. Solicit, integrate and summarize student responses. Give clues if necessary. Remind students that in brainstorming, no idea or suggestion is "silly." All ideas should be respectfully heard. Take an uncritical position, encourage wild ideas and discourage criticism of ideas. Have them raise their hands to respond. Record their ideas on the board. Ask the students:

- What different types of clothing do you use in different types of weather?

- What dangers do people face in extremely hot or cold weather and how can they be protected?

- What factors are important to consider when designing clothes? [Example ideas: Cost, quality, how long it takes to make a product, accessibility of materials, product life, appearance, utility, style, etc.]

Activity Embedded Assessment

Worksheet: Have students complete their designs, record measurements, and analyze material prototypes using the Materials Analysis Worksheet. Review their answers to gauge their mastery of the subject.

Post-Activity Assessment

Class Presentation: Have student groups present their new materials to the rest of the class and explain the thinking behind their designs. Have students discuss the effectiveness, comfort and durability of their materials. Have students also think about cost and aesthetic factors in their designs. These are all things engineers consider when developing new textiles or materials.

Re-Design Practice: Have students list any design changes they would make to their materials. What improvements could be made so the material functions even better in the specified weather conditions? How would you improve the process you created for testing the material? (This can be done following collaboration with the teacher or after class presentations.) During class presentations, involve the class in discussions that evaluate the pros and cons of each group's design.

Investigating Questions

Have you ever experienced extreme weather conditions? What was it like? What were you wearing?

How do you think engineers come up with their designs?

Why are engineers good at designing fabrics and materials?

Troubleshooting Tips

This activity is an open design, which can be challenging for students who are used to following exact procedures. Help students develop their procedures for testing the new layered material against wind, wetness and temperature by encouraging them to think about taping or stitching their material layers together, and using the thermometer to measure changes in temperature.

Measuring the temperature of the material that can withstand the cold ice may work best by wrapping the new material around the thermometer and measuring the temperature over a short amount of time.

Activity Extensions

Clothing for Different Climates: Assign each group a different extreme weather condition, such as a category five hurricane, a deserted tropical island on the equator with no shelters or shade, a tsunami, or an area with high winds and blowing objects.

Computers in My Clothing: The technology of integrating circuits or computers into textiles creates all types of possibilities for use in clothing for different weather climates. Have students brainstorm ideas for types of clothing that could be made from fabrics that contain circuits and computers. Have them each write a paragraph about a new article of clothing that uses this type of fabric. Encourage creativity and imaginative brainstorming.

Travelling Somewhere: Have the students plan a trip to another state or country. Have them think about how the weather will affect what they wear and what activities they do on a day-to-day basis. What types of clothing will they need? Have them present their breakdown in written paragraphs.

Activity Scaling

- For upper grades, integrate cost as a limiting factor in their creations. Assign a budget to each group and a "cost" to the available materials. For example, a 1 square foot of cotton fabric might cost $3 dollars. This requires teams to budget the amount of materials they use.

- For lower grades, give students more assistance in thinking about what the weather condition would feel like and how to test the different weather factors on their materials. Show students each available material individually and discuss the properties of that material as a group. Limit students to fewer materials for testing.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!Copyright

© 2007 by Regents of the University of Colorado.Contributors

Malinda Schaefer Zarske; Marissa Forbes; Glen Sirakavit; Janet YowellSupporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of these digital library curricula were developed by the Integrated Teaching and Learning Program under National Science Foundation GK-12 grant no. 0338326. However, these contents do not necessarily represent the policies of the National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: March 22, 2022

User Comments & Tips