Quick Look

Grade Level: 7 (6-8)

Time Required: 3 hours

(can be split into two 75-minute sessions)

Expendable Cost/Group: US $5.00

Group Size: 3

Activity Dependency: None

Subject Areas: Life Science, Science and Technology

NGSS Performance Expectations:

| MS-ETS1-3 |

Summary

As an introduction to bioengineering, student teams are given the engineering challenge to design and build prototype artificial limbs using a simple syringe system and limited resources. As part of a NASA lunar mission scenario, they determine which substance, water (liquid) or air (gas), makes the appendages more efficient.Engineering Connection

Bioengineering technologies explore the production of mechanical devices, products, biological substances and organisms that are created to improve health and/or contribute improvements to our daily lives.

Learning Objectives

After this activity, students should be able to:

- Describe how movements of bones are dependent upon the interaction of pairs of muscles.

- Identify the major bones and muscles of the arm and leg.

- Explain that a force (push or pull) is needed for movement.

- Explain that movement is a complex process involving more than one body system.

- List all body systems involved in movement.

- Describe how the location of muscle attachment is important to the movement of the bone.

- List and describe the working of different joints.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-3. Analyze data from tests to determine similarities and differences among several design solutions to identify the best characteristics of each that can be combined into a new solution to better meet the criteria for success. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Analyze and interpret data to determine similarities and differences in findings. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: Sometimes parts of different solutions can be combined to create a solution that is better than any of its predecessors.Alignment agreement: Although one design may not perform the best across all tests, identifying the characteristics of the design that performed the best in each test can provide useful information for the redesign process—that is, some of the characteristics may be incorporated into the new design.Alignment agreement: | |

Common Core State Standards - Math

-

Fluently add, subtract, multiply, and divide multi-digit decimals using the standard algorithm for each operation.

(Grade

6)

More Details

Do you agree with this alignment?

-

Solve unit rate problems including those involving unit pricing and constant speed.

(Grade

6)

More Details

Do you agree with this alignment?

-

Know the formulas for the volumes of cones, cylinders, and spheres and use them to solve real-world and mathematical problems.

(Grade

8)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Make two-dimensional and three-dimensional representations of the designed solution.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Develop innovative products and systems that solve problems and extend capabilities based on individual or collective needs and wants.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Create solutions to problems by identifying and applying human factors in design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Identify the general functions of the major systems of the human body (digestion, respiration, reproduction, circulation, excretion, protection from disease, and movement, control, and coordination) and describe ways that these systems interact with each other.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Demonstrate methods of representing solutions to a design problem, e.g., sketches, orthographic projections, multiview drawings.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Describe and explain the purpose of a given prototype.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify and describe three subsystems of a transportation vehicle or device, i.e., structural, propulsion, guidance, suspension, control, and support.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain examples of adaptive or assistive devices, e.g., prosthetic devices, wheelchairs, eyeglasses, grab bars, hearing aids, lifts, braces.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Describe and explain adaptive and assistive bioengineered products, e.g., food, bio-fuels, irradiation, integrated pest management.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- 14-10 ml oral syringes

- 7-30 cm length pieces of ¼-inch aquarium tubing

- 20 Popsicle sticks

- 5 rubber bands

- 1 meter of duct tape

- string

- water

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/hydraulic_joy] to print or download.Pre-Req Knowledge

Students should have prior experience with, or an introduction to the following concepts: hydraulics, joints, muscles, tendons, ligaments, bones, states of matter.

Introduction/Motivation

Your engineering challenge: NASA is setting up a workstation on the moon. You are part of a team that has just landed on the moon. One of your team members has an artificial arm and leg and has lost functionality of his limbs. It is up to your team to design and build one of the replacements. The only materials at your disposal are string, duct tape, Popsicle sticks, water and aquarium tubing and these materials must be shipped from the main shuttle located above the moon to the station where your team is located.

Procedure

Basic Procedure

- Direct each group to design a robotic arm or leg that simulates the body movement of that part. Inform students about the available resources.

- Require groups to create sketches with all parts labeled. For example: Popsicle sticks representing bones and the bone labeled (humerus). Please refer to the design sketch rubric.

- Have teams indicate how many syringes, Popsicle sticks, rubber bands and length of duct tape and/or string are needed. Have them fill out materials request forms and submit them in order to obtain the materials.

- Direct groups to build device prototypes.

- Test and evaluate the design based on the provided rubric.

- Have each group share its design with the class and demonstrate how it works in relation to movements and parts of the body. Remember to use appropriate terminology.

How to Create a Hydraulic System

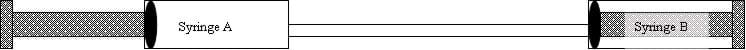

- Put together two syringe sub-systems. Define a sub-system as a piece of tubing with a syringe attached at each end. See Figure 1.

Figure 1. A syringe sub-system. - Fill one sub-system with water. Do this by removing both plungers from the syringes.

- Now place the open end of the syringe side A under a water faucet while holding syringe B at a lower elevation. Fill the sub-system with water until it overflows. Turn water off.

- Holding both syringes A and B at an equal elevation, place plunger A into syringe A and push plunger SLOWLY all the way down. Water will enter syringe B, filling it completely.

- Finally, place plunger B into syringe B. Make sure that the plunger is in contact with water and not air. If necessary, top off syringe B with water.

- This is a hydraulic sub-system because it contains a liquid. The other sub-system is filled with air (gas) and it is called a pneumatic sub-system.

Vocabulary/Definitions

articulate: To connect with a joint.

bone: Rigid connective tissue that makes up the skeleton of vertebrates.

compression: The process of pressing items together.

contract: To draw or squeeze together so as to make or become smaller or shorter and broader.

force: To break open or through.

gas: A phase of matter in which the molecules are widely separated, move around freely, and move at high speeds.

ligament: A tough band of tissue that holds bones together or keeps an organ in place in the body.

liquid: A phase of matter that is free to conform to a shape of a vessel, but has a fixed volume and has a greater density than a gas.

muscle: A body tissue consisting of long cells that can contract and produce motion.

Newton: A unit of force that is of such size that under its influence a body whose mass is one kilogram would experience an acceleration of one meter per second per second.

relax: To make or become loose or less tense.

solid: A phase of matter characterized by resistance to deformation and changes of volume.

system: A group of objects or units combined to form a whole and to move or work together.

tendon: A tough cord or band of dense white connective tissue that links a muscle to some other part.

Assessment

Pre-Activity Assessment: Have students draw diagrams of arms and/or legs. Have them indicate the locations of muscles, ligaments and tendons, and explain how they work.

Activity Embedded Assessment: Have students keep journals of their daily accomplishments.

Pre-Activity Assessment: Evaluate students' abilities to present and explain how the arms/legs work using the appropriate terminology, as it relates to the rubric.

Safety Issues

Beware of a rubber band flying out of control or a Popsicle stick making an unscheduled detour across the room.

Troubleshooting Tips

- Students may have difficulty filling up the tubing and syringes with water. Make sure no air is in the line.

- Students' arm or leg prototypes may buckle. If this happens, sugget that students adjust the rubber band placement.

Activity Extensions

Math Activity Idea

NASA has accepted your design and wants to have several devices on hand to avoid any further delays in the future.

- Based on the material used by your team, create a list of materials, amounts used, and prices for a single device.

- Now compute the cost for 5, 10, 25 and 100 devices. Your material supplier will reduce your cost by 15% if you make 100 devices. How much can you save with this 15% discount?

Math Activity Materials for Each Group:

- 15-10 ml oral syringes

- 8-30 cm length pieces of 1/4-inch aquarium tubing

- 6 Popsicles sticks

- 5 rubber bands

- 1 meter of duct tape

Math Activity Attachments

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students extend their knowledge of the skeletal system to biomedical engineering design, specifically the concept of artificial limbs and joints. Students relate the skeleton as a structural system, focusing on the leg as structural necessity. They learn about the design considerations involved in t...

Copyright

© 2013 by Regents of the University of Colorado; original © 2005 Worcester Polytechnic InstituteSupporting Program

K-12 Outreach Office, Worcester Polytechnic InstituteLast modified: August 17, 2018

User Comments & Tips