Quick Look

Grade Level: 6 (5-7)

Time Required: 2 hours

(can be split into two 60-minute sessions)

Expendable Cost/Group: US $4.00

Group Size: 2

Activity Dependency: None

Subject Areas: Physical Science, Physics

NGSS Performance Expectations:

| 3-5-ETS1-1 |

| 3-5-ETS1-2 |

| MS-ETS1-2 |

| MS-PS3-5 |

Summary

Student pairs design, build, and test model vehicles capable of rolling down a ramp and then coasting freely as far as possible. The challenge is to make the vehicles entirely out of dry pasta using only adhesive (such as hot glue) to hold the components together. Creativity is encouraged and different types of pasta are provided to support different functions such as round pasta for wheels and sheet pasta for the chassis. Students become familiar with the concepts of gravitational potential energy, kinetic energy and rolling resistance. Teams follow the steps of the engineering design process as they design, test and redesign their small-sized vehicles, working within the project's material constraints. The winner of the competitive final event is the pasta car that travels the longest distance beyond the bottom of the ramp.

Engineering Connection

The activity requires students to think about using a familiar food product as a building material. The primary challenge of the activity is the pasta material constraint. The material is both fragile and not designed to function as a material for a rolling vehicle. Similar to how real-world engineers must find solutions within design constraints such as material, weight and cost limitations, students learn how challenging this can be. For example, mechanical engineers may yearn to design a car frame with the lightest, yet strongest material available, but doing so would cost so much that the car would be unaffordable! Engineers strive to find an acceptable balance, such as creating a strong, safe and relatively lightweight frame, while keeping the material and production costs affordable for the manufacturer and end consumer. In the activity, students also experience the steps of the engineering design process as they brainstorm, prototype, test, evaluate and modify their designs to evolve them into successful solutions.

Learning Objectives

After this activity, students should be able to:

- Identify the type of energy a vehicle has at the top of a ramp.

- Explain that gravitational potential energy is how the car gains speed.

- Explain the logic of changes made to a design after a prototype test.

- Explain what is meant by a design constraint.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-1. Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a simple design problem that can be solved through the development of an object, tool, process, or system and includes several criteria for success and constraints on materials, time, or cost. Alignment agreement: | Possible solutions to a problem are limited by available materials and resources (constraints). The success of a designed solution is determined by considering the desired features of a solution (criteria). Different proposals for solutions can be compared on the basis of how well each one meets the specified criteria for success or how well each takes the constraints into account. Alignment agreement: | People's needs and wants change over time, as do their demands for new and improved technologies. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-2. Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Generate and compare multiple solutions to a problem based on how well they meet the criteria and constraints of the design problem. Alignment agreement: | Research on a problem should be carried out before beginning to design a solution. Testing a solution involves investigating how well it performs under a range of likely conditions. Alignment agreement: At whatever stage, communicating with peers about proposed solutions is an important part of the design process, and shared ideas can lead to improved designs.Alignment agreement: | Engineers improve existing technologies or develop new ones to increase their benefits, to decrease known risks, and to meet societal demands. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-PS3-5. Construct, use, and present arguments to support the claim that when the kinetic energy of an object changes, energy is transferred to or from the object. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Construct, use, and present oral and written arguments supported by empirical evidence and scientific reasoning to support or refute an explanation or a model for a phenomenon. Alignment agreement: Science knowledge is based upon logical and conceptual connections between evidence and explanations.Alignment agreement: | When the motion energy of an object changes, there is inevitably some other change in energy at the same time. Alignment agreement: | Energy may take different forms (e.g. energy in fields, thermal energy, energy of motion). Alignment agreement: |

Common Core State Standards - Math

-

Fluently multiply multi-digit whole numbers using the standard algorithm.

(Grade

5)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Evaluate designs based on criteria, constraints, and standards.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Design involves a set of steps, which can be performed in different sequences and repeated as needed.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

California - Math

-

Fluently multiply multi-digit whole numbers using the standard algorithm.

(Grade

5)

More Details

Do you agree with this alignment?

California - Science

-

Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Construct, use, and present arguments to support the claim that when the kinetic energy of an object changes, energy is transferred to or from the object.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- a supply of dry pasta in a variety of shapes to serve as vehicle building material, such as large and flat lasagna noodles for car chassis, spaghetti for car axles, rotelle for wheels, penne to serve as bushings, etc.

- hot glue and glue gun; hot glue is the recommended adhesive because of the surface irregularities of pasta; alternatively, provide the instructor's choice of adhesive

- Spaghetti Soapbox Derby Pre/Post Quiz, two each per student

- Construction and Competition Rules

- Spaghetti Soapbox Derby Judging Instructions

- paper and pencil, for sketching designs

To share with the entire class:

- (optional) a small wheeled vehicle, such as a toy, for a quick demo, to let run down the ramp with different amounts of weight to demonstrate the resulting differences in distance traveled

- (optional) access to a computer with Internet access, for students to research example pasta cars OR for the teacher to find the same pictures in advance to print out to show the class

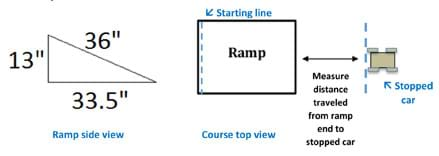

- test ramp for testing the pasta cars; such as a ramp composed of a 36 x 24-inch (91 x 61-cm) sheet of thin plywood, foam core board or similar materials that is raised on one side to a height of 13 inches (33 cm), perhaps propped on books or boxes secured with tape; see Figures 2 and 3 for details

- masking tape

- meter stick, yardstick or measuring tape

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/ucd_derby_activity1] to print or download.Pre-Req Knowledge

- Able to use a meter stick or ruler to measure distance.

- Some knowledge of kinetic and potential energy so as to be able to explain the conversion between gravitational potential energy and kinetic energy.

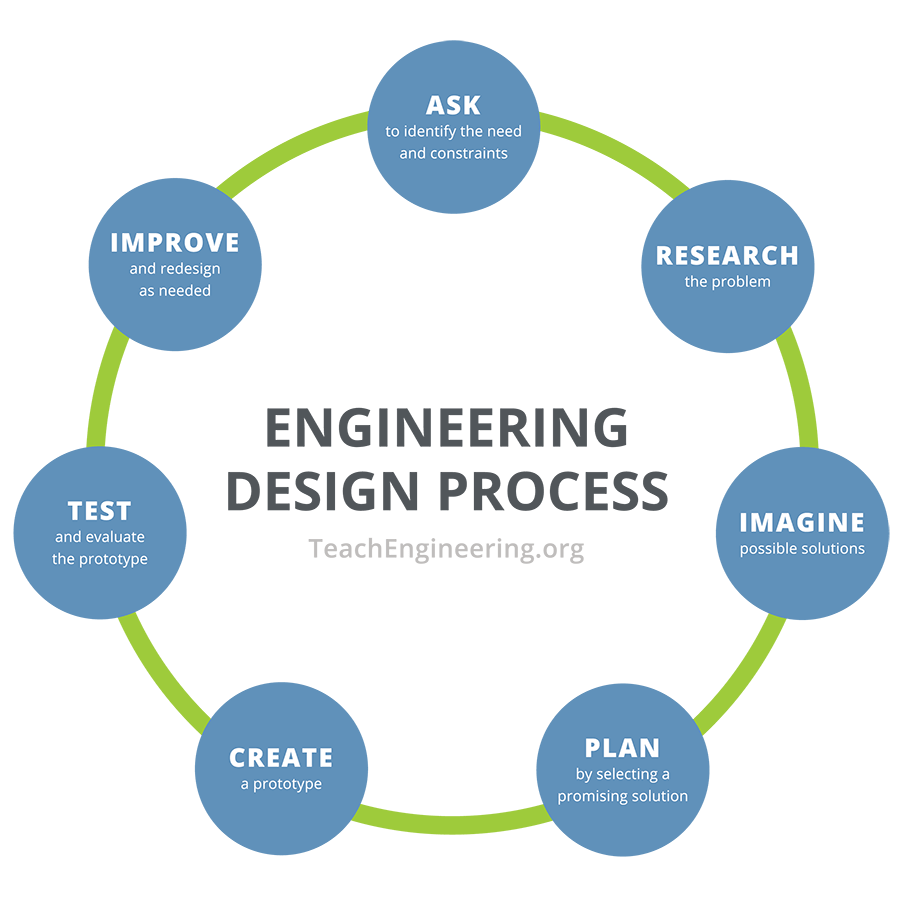

- A basic understanding of the steps of the engineering design process (see Figure 1).

Introduction/Motivation

Imagine riding in a car made entirely of pasta! Well, you won't be driving this car any time soon, but you will have a chance to design a model vehicle made from this popular cuisine. Your task is to design a vehicle made entirely of dry pasta that is able to roll down a ramp and coast freely as far as possible. I bet you are already imagining a number of challenges that you might face in attempting to make pasta roll!

As you create your vehicle, you will follow the universal steps of the engineering design process. These are the same steps that real engineers use to design all the types of products in our world and every one of those products, structures and projects must meet its own unique design constraints. Design constraints are the requirements (criteria) and limitations that the solution must meet.

For this challenge, your main design constraint is that all components of the vehicle must be constructed of some form of dry pasta. Here's a tip: Before you start putting any pieces of pasta together, think about how each part of the vehicle will function. It is always a good idea to discuss your ideas with everyone on your team and sketching out ideas helps you to explain your ideas and remember them. Once you have decided what each component needs to do—such as the chassis, wheels and axles—find pasta pieces that seem the most suitable for those purposes. For example, how far might your car coast if you use a square piece of pasta for the wheels? That's right—not far at all!

Remember that it is highly unusual for a design to be perfect on the first attempt. When you test your prototype pasta cars, look at every vehicle component and see if it is doing its job well. If one car design does not work, that does not mean the entire car is a failure. Examine each piece and decide whether or not it was a good design choice. Take what you learn from testing each design iteration and incorporate the components that worked into the next version, making improvements on the parts that didn't work as well. Doing this is a big part of the engineering design process: examining what works and what does not, without getting discouraged so you can make changes for improvement.

Real-world engineers may not build cars made from pasta, but the idea of selecting the best material for the task—such as the shape/type of pasta in this activity—is a process that engineers all go through when they design vehicles—or anything! And, every vehicle that engineers design must meet its own design constraints on its properties, everything from weight and size to speed, power, time and cost.

Procedure

Background

This hands-on activity is designed for students to experience some trial and error. However, some fundamental scientific knowledge can help students create more successful vehicles: The distance traveled by the vehicle is related to both the kinetic energy the vehicle obtains rolling down the ramp, and the rolling resistance. The following information explains these concepts.

The car gains speed as it rolls down the ramp, which is a demonstration of the conversion from gravitational potential energy to kinetic energy. The gravitational potential energy of an object is related to the force from gravity acting to pull the object downward. The further an object is away from the "ground" and the heavier the object, the more gravitational potential energy it has. This is analogous to moving the pasta car higher up the ramp or increasing its weight by adding more material. At the start of each trial, all of the car's energy comes from its gravitational potential, so increasing this is advantageous.

Kinetic energy is the energy associated with the motion of an object and is related to the object's mass and how fast it is traveling. The more kinetic energy a vehicle has while traveling down the ramp, the further it can roll once it reaches the floor. The law of conservation of energy states that energy is neither created nor destroyed, thus it must come from some other form of energy. This means that the kinetic energy that the car has while rolling down the ramp is directly related to the potential energy it had while at the top of the ramp. If the height at which the car is released is fixed, then the only way to increase the car's potential energy is to increase the weight of the car.

While from an energy perspective, a heavier vehicle has a clear advantage, some negative impacts exist as well. The rolling resistance of a vehicle is related to the friction in the moving components and acts against the motion of the car, slowing the car down. The force equal to this rolling resistance is how much force is required to keep the car moving at a constant speed. This can be thought of as how difficult it is to push the car forward. A heavier car generally has more rolling resistance and puts more stress on the fragile pasta components. With this in mind, a compromise must be made to find the ideal weight so that the car is heavy enough to generate a fair amount of kinetic energy, while not too heavy that the vehicle breaks under its own weight.

From an engineering perspective, the last important design consideration is to minimize the rolling resistance. This means selecting wheels that roll smoothly, attaching every component as straight as possible and trying to limit the contact between moving parts. The friction between moving components "wastes" some of the car's kinetic energy. The more friction, the more energy is wasted and the shorter the distance the car will travel before coming to a stop.

In this activity, students follow the steps of the engineering design process as they design, test and redesign their small-sized vehicles. Refer to Figure 1 for the steps of the engineering design process.

The Procedure section guides the activity through all steps of the engineering design process, with a brief summary provided here:

- The challenge/problem is to design a vehicle with the constraint that it must be built entirely out of dry pasta and able to roll down a provided ramp as far as possible.

- Students research the problem by observing photos/models of other pasta vehicles and/or examining and experimenting with the given materials.

- Each student group brainstorms and discusses together the ideas they have for the team design.

- Each group agrees to the design they will attempt to build.

- Teams construct their selected designs.

- Teams test their prototypes as they are being built to make sure each component functions as intended.

- If vehicles fails to roll freely beyond the ramp, students analyze what worked and did not work to improve the prototypes before the final test/competition.

Before the Activity

- Gather materials and make copies of the Construction and Competition Rules and Spaghetti Soapbox Derby Judging Instructions, one each per group, and the Spaghetti Soapbox Derby Pre/Post Quiz, two copies per student.

- Acquire enough dry pasta for all the participating groups, providing enough variety in pasta type to successfully build functioning vehicles. For example make sure each group at least has some round pasta to use wheels and spaghetti to use as axles.

- Decide how you want to distribute the dry pasta, for example, provide each group with a set assortment of pieces or let teams choose what they want from all pasta at one classroom location.

- (optional) Make an example pasta car to give students an idea of what they are attempting to build.

- (optional) Decide whether or not you want students to conduct their own online research to find examples of pasta cars, or if you want to find some examples in advance to show them, or if you want to conduct the activity without this sort of research input.

- Construct a testing ramp. Refer to the rules, judging instructions and Figures 2 and 3 for suggested dimensions and course layout. Use books/boxes and masking tape to prop up the ramp securely, so it does not change between trials. Use masking tape to mark the starting line at the top of the ramp and a test area on the floor, leaving a stretch of open space at the bottom of the ramp for the little cars to run until they stop.

Figure 2. Suggested vehicle testing ramp and course layout.

With the Students: Background Concepts and the Challenge

- Administer the post-quiz, as described in the Assessment section.

- Review with the class the concepts of kinetic and potential energy, as well as the law of conservation of energy. Refer to the information in the Background section. With so much material available on the topic of energy, it is up to the teacher to determine how in-depth to explore the concepts. At a minimum, present to the class the following three ideas.

- Gravitational potential is the stored energy due to an object's height above the ground. It is dependent on the object's distance from the ground and its mass (if the concept of mass has not been taught, equate mass to weight). To illustrate the dependence on mass, ask students if they would rather have a brick or a piece of foam fall on their toes? Then ask students: If a brick was dropped on your foot, would it hurt more if it was dropped from a centimeter above the foot or if it dropped from a meter off the ground? Depending on the class math level, introduce the equation for potential energy: PE = m x g x h where m is the mass, g is gravitational acceleration and h is the height above the ground. Then enter some numbers for the different variables to show that if g and h are fixed, all you can change is m.

- Kinetic energy is energy associated with an object's motion. It is dependent on how fast an object is traveling and the object's mass (if the concept of mass has not been taught, equate mass to weight). Quick demo: Let a small wheeled vehicle (perhaps a toy, not made of pasta) run down the ramp numerous times, adding more and more weight to the car each run to show the resulting differences in distance traveled.

- The vehicle's kinetic energy as it rolls down the ramp is a result of the conversion from the gravitational potential energy the car had at the top of the ramp. Thus, at the start of each trial, all of the energy a car possesses is from its gravitational potential.

- Present to the class the Introduction/Motivation content. This introduces the idea of designing a vehicle made entirely of dry pasta. Make sure students are clear about the basics of the activity such as: the vehicle must be able to roll down a ramp and coast freely as far as possible.

- As necessary, clarify the definition of a design constraint. Sometimes it helps to tie the idea into real-world examples. Make sure students realize that the biggest constraint in the challenge is that the vehicle must be built entirely of dry pasta and glue.

- Spend time going over the anticipated challenges as a class, so students can begin thinking of how they would like to try and solve them.

- Demonstrate how easy it is to break the pasta as a way to make sure students know that dry pasta is fragile and needs to be handled carefully. Advise students to consider the fragility of the material in their designs.

- Introduce the idea of rolling resistance. Explain the concept by asking students to consider how much force is required to push a vehicle a certain distance. For example, a car that rolls smoothly and can travel a long distance with a single push has a low rolling resistance while one that stops soon after a push has a high rolling resistance.

- Go over the rules sheet with students.

- (optional) Show an example of completed pasta car to give students an idea of what they are attempting to build.

- Emphasize that the engineering design process is about testing and learning from mistakes and not to let a failed design discourage students from trying more.

With the Students: Research, Brainstorming, Design and Construction

- Divide the class into student pairs.

- Have students conduct some research related to the challenge. This might include letting them research some pasta car designs on the Internet, showing them some (already found) pictures and/or giving them time to examine and experiment with the given materials. (15 minutes)

- Direct the groups to brainstorm, sketch and discusses together the ideas they have for a team design.

- Have each team agree to a design they will attempt to build. Require them to sketch the design, specifying the types of pasta they wish to use for each component. (15 minutes)

- Distribute the pasta supplies to each team or have students choose the dry pasta materials they need from a central classroom location. (60 minutes for the remaining steps)

- Review with students the different techniques for attaching different pieces of pasta with the provided adhesive. Depending on the type of adhesive used, supervise or provide assistance, especially if hot glue is used.

- Advise students to experiment and test partially built vehicles and/or sub-assemblies often to make sure they roll and can survive the ramp. Making the effort to test and troubleshoot periodically throughout the engineering design process prevents students from spending too much time building non-functional vehicles.

A student shows off their car on test day.

With the Students: Final Testing/Competition

- One by one, have teams bring their final prototype vehicles to the test ramp (see Figure 3). Expect 30 minutes to be enough time for a class of ~30 students working in pairs to test their pasta cars.

- A run consists of holding a pasta car at the top of the ramp with the rear wheels touching the starting line, then releasing the car and letting it roll freely down the ramp and coast until it comes to a stop.

- Prior to the final competition run, review as a class the judging instructions. Judging is done by measuring the perpendicular distance from the bottom of the ramp to the closest part of the stopped pasta car.

- Time permitting, let teams make adjustments to their vehicles after their first tests and then re-test for the final competition.

- On the classroom board, record the results. Rank the entries by the furthest distance traveled, as measured from the bottom of the ramp. Recognize the winning team.

Figure 3. Example test ramp setup.

With the Students: Review and Reflect (20 minutes)

- Based on the class results, have the entire class examine in more detail the vehicles that performed best. Lead a class discussion to explore why the top pasta cars worked well. Encourage all students to provide ideas.

- Ask students to share their stories about making design changes based on what they learned from their interim and troubleshooting tests.

- Have each group discuss together what they would change in the team design given what they observed during the class runs.

- Administer the pre-quiz, as described in the Assessment section.

Vocabulary/Definitions

brainstorming : A group problem-solving method to stimulate creative thinking in which each person in a group presents his or her ideas in an open discussion forum, with the purpose to come up with a great number of different ideas.

constraint : A limitation or restriction. For engineers, design constraints are the requirements and limitations that the final design solutions must meet. For example, a rocket must have a mass of less than a specified amount.

engineering design process: The cycle that engineers go through while creating new devices (or products, structures, techniques, etc.). The main steps include identifying a need, researching the problem, generating ideas, selecting a solution, building a prototype, testing and evaluating the solution(s), improving and redesigning as necessary, and presenting the results. The steps may be performed in different sequences and repeated as needed.

kinetic energy: The energy associated with the motion of an object.

potential energy : The stored energy of an object, from gravity or other field force.

prototype: A first attempt or early model of a new product or creation. May be revised many times.

rolling resistance: A force resisting the motion of an object rolling on a surface. Often caused by the moving components of a vehicle and/or its interaction with the surface. In other words, how difficult it is for the car to freely roll.

Assessment

Pre-Activity Assessment

Pre-Quiz: Administer the five-question Spaghetti Soapbox Derby Pre/Post-Quiz to assess students' prior knowledge on gravitational potential and kinetic energy, as well as the concepts of rolling resistance and design constraints.

Activity Embedded Assessment

Check-In: While prototype construction is going on, roam around the class and ask groups what decisions they made in order to come up with the team design. Ask students to explain why they made those decisions. Also ask students how they are using their knowledge of energy concepts to inform their designs.

Calculating Energy: Have students use a scale to determine the mass of the vehicle and then measure the height at which the car is released at the top of the ramp to determine its gravitational potential energy at the start of the trial. Have groups compare results to see if the car with the greatest gravitational potential energy at the start traveled the furthest distance.

Post-Activity Assessment

Class Discussion: After the competition is finished, have the creators of the most successful designs (or all groups if time permits) share with the class their final pasta car designs, how they arrived at the final designs, and what did and did not work well during testing. Take note of students' contributions to gauge their engagement and depth of comprehension. Ask the students:

- Why did the top pasta cars work so well?

- What sorts of design changes did you make from what you learned from your interim and troubleshooting tests?

- If you had one more chance to improve your prototype, what changes would you make?

Post-Quiz: Administer the Spaghetti Soapbox Derby Pre/Post-Quiz again. Compare students' pre/post answers/scores to assess their learning from the activity.

Safety Issues

If hot glue is used to fabricate the pasta cars, provide students with safety instructions. Supervise students when they use the hot glue guns or arrange for adult assistants to help them by applying hot glue for them.

Troubleshooting Tips

Some pieces of round pasta are more round than others. Take the time to sort out the more oblong and oval shapes to improve students' vehicles.

It is important to attach the axles as straight as possible in order to help cars roll straight and smoothly.

One thing to consider is that the pasta cars experience more force at the transition from the end of the ramp to the floor, so while prototype cars might be strong enough when rolled on a level surface, the real test is if they can survive the ramp.

It is best to run the vehicles on a smooth surface such as a linoleum-covered floor; carpet slows the cars down a lot once they have rolled off the ramp.

Activity Extensions

Assign students to each build at home a pasta car of their own design to beat the one they built in class.

Activity Scaling

For students in lower grades, reduce the emphasis on energy a bit and shift the focus to just building the cars. One way to make the activity a little easier is to create one basic design for all students to build and then have them make modifications once they have successfully built the base model.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn how the aerodynamics and rolling resistance of a car affect its energy efficiency through designing and constructing model cars out of simple materials. As the little cars are raced down a tilted track (powered by gravity) and propelled off a ramp, students come to understand the need...

Copyright

© 2015 by Regents of the University of Colorado; original © 2015 University of California DavisContributors

Chris LangelSupporting Program

RESOURCE GK-12 Program, College of Engineering, University of California DavisAcknowledgements

The contents of this digital library curriculum were developed by the Renewable Energy Systems Opportunity for Unified Research Collaboration and Education (RESOURCE) project in the College of Engineering under National Science Foundation GK-12 grant no. DGE 0948021. However, these contents do not necessarily represent the policies of the National Science Foundation, and you should not assume endorsement by the federal government.

Many thanks to the University of California Davis RESOURCE Fellows, along with supervisors Alisa Lee, Jean VanderGheynst and Travis Smith.

Last modified: April 8, 2021

User Comments & Tips