Quick Look

Summary

Students experience the engineering design process as they design, fabricate, test and redesign their own methods for encapsulation of a (hypothetical) new miracle drug. As if they are engineers, teams make large-size prototypes to test proof of concept. They use household materials (tape, paper towels, plastic wrap, weed-barrier fabric, glues, etc.) to attach a coating to a porous "shell" (a perforated plastic Wiffle® ball) containing the medicine (colored drink mix powder). The objective is to delay the drug release by a certain time and have a long release duration—patterned after the timed release requirements of many real-world pharmaceuticals that are released from a polymer shell via diffusion in the body. Guided by a worksheet, teams go through at least three design/test iterations, aiming to achieve a solution close to the target time release constraints.Engineering Connection

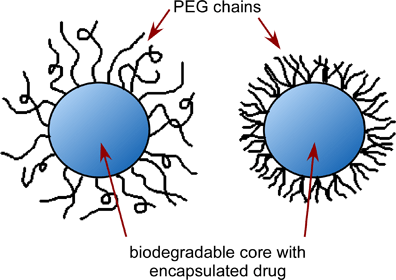

Engineers use polymers in encapsulation designs to facilitate the administration of drugs made of high molecular weight molecules. Students act as biomedical and chemical engineers following the steps of the engineering design process to design, test and improve drug encapsulation prototypes using representative materials.

Learning Objectives

After this activity, students should be able to:

- Describe the steps of the engineering design process and the value of testing and redesign.

- Explain how diffusion works for their prototypes.

- Elaborate on the importance of design considerations for engineers.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of society in the development and use of technology.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the relationships among technologies and the connections between technology and other fields of study.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Texas - Science

-

communicate valid conclusions supported by the data through methods such as lab reports, labeled drawings, graphic organizers, journals, summaries, oral reports, and technology-based reports.

(Grades

9 -

11)

More Details

Do you agree with this alignment?

-

design and implement investigative procedures, including making observations, asking well-defined questions, formulating testable hypotheses, identifying variables, selecting appropriate equipment and technology, and evaluating numerical answers for reasonableness;

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- 1 perforated, hollow plastic ball, such as a 4-inch diameter Wiffle® ball; such as a pack of 6 for $5.49 at Target (see Figure 1); save any plastic netting that comes with the packaging

- colorful drink flavoring powder, such as a Kool-Aid® packet for 20¢ at grocery stores or as available in multi-serving containers

- There Will Be Drugs Worksheet, one per student

- (optional) computers/tablets with Microsoft® PowerPoint® or other drawing application, for students to draw design diagrams; alternative: have students draw by hand using paper and pencil

Figure 1. Activity materials.

General prototype fabrication supply materials (suggestions; add or omit as desired):

- paper towels

- newspaper

- printer paper

- cardboard

- shop towels, such as a three-pack for $6.28 at Home Depot

- dish packing foam, such as a 50-ft dish foam roll for $7.48 at Home Depot

- weed-barrier landscape fabric, such as 3-ft x 50-ft roll for $9.97 at Home Depot

- plastic cling wrap

- bubble wrap

- balloons

- papier-mâché materials (again, just a suggestion; add or omit as desired)

- flour

- glue, such as Gorilla Wood Glue® and/or Elmer's® glue

- duct tape

- masking tape

- paint tray liner, such as one for 98¢ at Home Depot

Testing materials (ideally one testing station per group; see Figure 2):

- buckets, sinks, tubs or a small plastic pool, such as 5-gallon buckets for $3 each at hardware stores

- water and sink; if drink mix colors the water, replace with clean water for next test

- waterproof weights, such as metal washers or bricks

- lightweight plastic netting, saved from the Wiffle® ball packaging

- string or twine; use the string, netting and weights to hold the prototypes underwater during testing

- stopwatches or other timers

To share with the entire class:

- scissors

- extra paper for sketching

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uoh_body_lesson01_activity1] to print or download.Pre-Req Knowledge

A basic understanding of drug encapsulation and how diffusion works, as presented in the associated lesson, Get in My Body: Drug Delivery.

Introduction/Motivation

(Introduce to the class the following hypothetical scenario.) Congratulations, you have invented a new miracle drug for the treatment and prevention of a harmful disease! The drug is designed to be taken orally. However, the drug cannot be released immediately into the body because the patients would die of toxic doses. So, we need to design an encapsulation coating that prevents the pharmaceutical from being released immediately upon placement into an aqueous environment.

Before a company will purchase your drug design, you must prove to them that the encapsulation works by demonstrating it with a large-scale model. They want to see you demonstrate control over the drug's initial release time and duration time. In engineering and technology, a rough prototype of a new method or idea is often constructed as a "proof of concept" to demonstrate that it is feasible and worth pursuing.

For this engineering challenge, you will use only simple household materials to create a large-scale encapsulation model, and biocompatibility will not be taken into account. We will use a colorful flavored drink mix, like Kool-Aid® powder, to represent your new, miracle drug molecules that need to be placed inside the fully built shell before closure.

After brainstorming a design with your team and building it with the available materials, you will test your design prototype by holding it underwater (in a bucket, sink, tub, etc.) and timing how long it takes for the drug (that is, the colored drink powder) to release—or whether it releases at all. You will know that your drug has been released when the water changes color!

Procedure

Background

Early on, pharmaceuticals were administered by simple methods such as eating medicinal herbs, infusing tea with medicinal compounds and applying apothecary-made pastes and salves. The earliest medications were taken orally, topically and by inhaling vapors. Modern technological innovations now enable more complex medications to be delivered to specific body areas. For example, injections directly infuse drugs into the bloodstream and other implant and device inventions release drugs over time. Encapsulation methods make it possible for high molecular weight pharmaceuticals to be transported to specific body target locations.

In this activity, student teams are challenged to create large-scale drug encapsulation prototypes using everyday household materials. Colorful flavored drink mix, such as Kool-Aid® powder, is used to represent a medicine that must be protected from immediate release in water by the encapsulation shell. The prototype encapsulation designs are tested by submerging them in water; release is indicated when the water colors from the drink mix. Students experience how diffusion determines a material's usefulness to serve as the shell. The aim is to fully encapsulate the "drug" so that it does not immediately release.

Decide to either give students specific initial time release or duration design constraints—or both, adjusting the time constraints to fit your schedule needs. For example, you might specify that the drug begins to release after five minutes and the duration of release is 20 minutes. One group's first design attempt might release after five minutes, but only have a 10-minute duration. In this case, they redesign so that their improved iterations show more control over the release duration while maintaining the initial release time.

Before the Activity

- Make copies of the There Will Be Drugs Worksheet, one per student.

- Set up the supply table.

- Set up testing stations, each with a bucket with water, weights, lightweight netting, string and timer. Ideally, provide one testing station per group; alternatively, if sharing testing stations, stagger testing times. Use the string, netting and weights to hold the encapsulation prototypes underwater during testing.

- Determine the specific initial time release and/or duration time constraint goals for the activity (as described above). Feel free to get creative with the drug release time constraints that you impose on the design project; do what works well for your class. No matter the time constraints you decide upon, challenge students to iterate the engineering design cycle many times, improving and retesting their designs.

With the Students

- Lead a brief pre-activity class discussion to review drug delivery methods and concepts from the associated lesson, as described in the Assessment section.

- Present to the class the Introduction/Motivation section to introduce the hypothetical scenario and the engineering challenge (also explained at the top of the worksheet).

- Divide the class into groups of three students each (or let students choose their teams).

- Hand out the worksheets and show students the available materials at the supply table. Direct students to follow the worksheets and fill them in as they design their encapsulation prototypes.

- Introduce the specific drug release time constraints that you have chosen for the activity. Have students note these times on their worksheets.

- Remind students that they will be engaging in the steps of the engineering design process by brainstorming, selecting the most promising idea, drawing their designs, building prototypes, testing the prototypes and redesigning over and over to achieve the best solution possible. As necessary, review the basic steps of the engineering design process.

- This is a team project. Explain that all designs must be drawn by the group and subsequently seen and approved by the teacher before any fabrication begins.

- Monitor students as they fabricate their design prototypes. Assist them in enclosing a standard amount of drink powder inside each prototype.

- As necessary, assist students as they test their prototypes by placing them underwater in buckets or sinks. Use the lightweight plastic netting, string and weights to submerge the prototypes. Start timers when the encapsulated drug prototype is secured underwater. Advise students to carefully observe for the first signs of colored water escaping from the prototypes, and watch how the encapsulation materials behave during the test. Note and record the time elapsed when: 1) the water first begins to change color, and 2) all of the "drug" has been released from the shell.

- Prompt students to write down their testing results on their worksheets, including if and why their prototypes worked, or did not work, and what changes they intend make to their designs.

- As time permits, let groups redesign and retest multiple times (up to three or four iterations), aiming to demonstrate the capability of their prototypes to release the drug in a controlled fashion.

- After groups have finished testing, have them work on the last item on the worksheet—to compile summary diagrams that tells the story of how their designs evolved through testing, explaining what improvements they made and indicating timing results for each design iteration. This serves as a post-activity assessment; see the Assessment section.

- Collect students' completed worksheets for grading.

Figure 2. Student-created "drug" delivery encapsulation prototypes and testing.

Vocabulary/Definitions

constraint: A limitation or restriction. For engineers, constraints are the limitations and requirements that must be considered when designing a workable solution to a problem.

diffusion: The movement of molecules in a random fashion to create an evenly concentrated environment.

drug administration: As refers to pharmaceuticals, the method of drug delivery into the human body.

drug delivery: A method of transporting a pharmaceutical to a desired body location.

duration: The length of time something continues to exist, such as a drug release.

efficacy: The capacity for producing a desired result. For example, how much a drug is able to inhibit; if it causes 100% inhibition, it has a high efficacy.

encapsulation: As refers to pharmaceuticals, a shell-like method of coating drug molecules to enable release at specific times using diffusion.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products and systems. Typically, the steps include: defining a problem, researching the problem, brainstorming and generating ideas, selecting a most promising solution, creating a model or prototype, testing and evaluating the design using specifications, and improving and refining the design.

oral administration: A method of drug administration using the mouth and digestive tract to achieve adsorption into the bloodstream.

polymer: A large macromolecule that is composed of repeating subunits.

proof of concept: In engineering and technology, a rough prototype of a new method or idea created to demonstrate that it is feasible and worth pursuing.

solubility: The property of a substance to dissolve into solution.

toxicity: The degree of harmfulness of a substance to humans.

Assessment

Pre-Activity Assessment

Concept Review Discussion: Hold a class discussion to review concepts from the associated Get in My Body: Drug Delivery lesson. Ask students to explain the main methods of drug administration, including pros and cons for each, and list design considerations that engineers and doctors take into account for administering medications. Make sure students are familiar with the idea of drug encapsulation and how diffusion works.

Activity Embedded Assessment

Worksheet: Have students use the There Will Be Drugs Worksheet to guide them through three design/build/test iterations; if they have time for more testing and improvement, provide them with extra paper. Check their initial designs before they start to fabricate. Have them hand in their completed worksheets. Review their answers, sketches and testing results to gauge their depth of comprehension and engagement with the process.

Post-Activity Assessment

Summary Diagram of Designs and Improvements: As assigned at the end of the worksheet, have students compile diagrams that show how their groups' designs evolved through testing and redesign, explaining what improvements they implemented along with the initial release times and release duration times for each design. Have students use computers and applications like PowerPoint® if available; otherwise, draw and label by hand. Review their diagrams to gauge their understanding of the lesson and activity concepts.

Investigating Questions

How might layering of different materials help?

Does the number of layers of a material for the coating matter? Why?

How successful was your proof of concept?

Troubleshooting Tips

If using papier-mâché as an encapsulation material, be aware that problems can arise when adding the "drug" (drink flavor powder) if the structure is not completely dry—it can be hard to see when the drink powder releases from the papier-mâché encapsulation as the papier-mâché degrades in the water.

Choose a drink powder color that will be easy to see when it diffuses out of the encapsulation. For example, if testing in orange buckets, use purple or blue drink mix powder.

Activity Extensions

Engineers are typically required to consider materials cost as part of the design constraints. As an extension, assign different price values to each material and add to the challenge the constraint to design the encapsulation prototype for drink powder/drug release at the lowest possible cost. See how adding this constraint affects the final design and development.

Activity Scaling

- For lower grades, limit the encapsulation materials to only papier-mâché or only paper supplies held together with tape.

- For higher grades, hold students to a very specific time frame for initial release and release duration.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are challenged to think as biomedical engineers and brainstorm ways to administer medication to a patient who is unable to swallow. They learn about the advantages and disadvantages of current drug delivery methods—oral, injection, topical, inhalation and suppository—and pharmaceutical desi...

Students examine in detail the water cycle components and phase transitions, and then learn how water moves through the human-made urban environment. Students show their understanding of the process by writing a description of the path of a water droplet through the urban water cycle, from the dropl...

Copyright

© 2016 by Regents of the University of Colorado; original © 2015 University of HoustonContributors

Megan Ketchum; Andrea LeeSupporting Program

National Science Foundation GK-12 and Research Experience for Teachers (RET) Programs, University of HoustonAcknowledgements

This digital library content was developed by the University of Houston's College of Engineering under National Science Foundation GK-12 grant number DGE 0840889. However, these contents do not necessarily represent the policies of the NSF and you should not assume endorsement by the federal government.

Last modified: August 26, 2022

User Comments & Tips