Summary

Students act as biomedical engineers and follow the engineering design process to create and test custom orthotic insoles. They begin by asking questions to learn about foot-related medical problems, such as plantar fasciitis and flat feet, and identify how orthotics can help reduce pain or pressure. Next, they imagine possible insole designs that could support the foot and reduce impact during movement. During the plan stage, students sketch their ideas and select materials with varying foam densities to provide targeted support for their chosen foot condition. They then create a prototype orthotic using foam and hot glue based on their plan. To test their designs, students drop a weighted ball onto kinetic sand with and without their orthotics, measuring the depth of impact to determine how much pressure their design absorbs. Afterward, they improve their designs by analyzing test data, identifying areas of success, and considering modifications.Engineering Connection

Biomedical engineers study how the body interacts with materials and devices, then design and test solutions such as orthotics, prosthetics, and medical equipment to prevent injury or aid healing. For example, companies such as BMW employ engineers to address foot problems that arise from long hours of standing, using data and testing to develop orthotics that reduce impact and pressure. In this activity, students mirror that process by graphing data to refine their designs, gaining experience with skills biomedical engineers use daily. These concepts are essential in both sports and medicine, where understanding energy transfer, cushioning, and material behavior helps create products that protect, support, and enhance human performance.

Learning Objectives

After this activity, students should be able to:

- Describe how kinetic energy relates to the mass and speed of a moving object and how it transfers through materials.

- Design and build a prototype orthotic insole using different foam densities to reduce pressure on the foot.

- Collect, graph, and interpret data to evaluate the effectiveness of their orthotic design in cushioning impact forces.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: | Models of all kinds are important for testing solutions. Alignment agreement: The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-PS2-2. Plan an investigation to provide evidence that the change in an object's motion depends on the sum of the forces on the object and the mass of the object. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Plan an investigation individually and collaboratively, and in the design: identify independent and dependent variables and controls, what tools are needed to do the gathering, how measurements will be recorded, and how many data are needed to support a claim. Alignment agreement: Science knowledge is based upon logical and conceptual connections between evidence and explanations.Alignment agreement: | The motion of an object is determined by the sum of the forces acting on it; if the total force on the object is not zero, its motion will change. The greater the mass of the object, the greater the force needed to achieve the same change in motion. For any given object, a larger force causes a larger change in motion. Alignment agreement: All positions of objects and the directions of forces and motions must be described in an arbitrarily chosen reference frame and arbitrarily chosen units of size. In order to share information with other people, these choices must also be shared.Alignment agreement: | Explanations of stability and change in natural or designed systems can be constructed by examining the changes over time and forces at different scales. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-PS3-1. Construct and interpret graphical displays of data to describe the relationships of kinetic energy to the mass of an object and to the speed of an object. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Construct and interpret graphical displays of data to identify linear and nonlinear relationships. Alignment agreement: | Motion energy is properly called kinetic energy; it is proportional to the mass of the moving object and grows with the square of its speed. Alignment agreement: | Proportional relationships (e.g. speed as the ratio of distance traveled to time taken) among different types of quantities provide information about the magnitude of properties and processes. Alignment agreement: |

Common Core State Standards - Math

-

Model with mathematics.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Recognize and represent proportional relationships between quantities.

(Grade

7)

More Details

Do you agree with this alignment?

-

Use data from a random sample to draw inferences about a population with an unknown characteristic of interest. Generate multiple samples (or simulated samples) of the same size to gauge the variation in estimates or predictions.

(Grade

7)

More Details

Do you agree with this alignment?

-

Construct and interpret scatter plots for bivariate measurement data to investigate patterns of association between two quantities. Describe patterns such as clustering, outliers, positive or negative association, linear association, and nonlinear association.

(Grade

8)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Apply the technology and engineering design process.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Assess design quality based upon established principles and elements of design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Create solutions to problems by identifying and applying human factors in design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Refine design solutions to address criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- foam for orthotic prototypes sheet (medium density), ~20 cm x 30 cm (~8 in. x 12 in.) – for base insole

- air dry foam for extra support – for customizing support

- 1 small piece each of soft and firm density foam, ~10 cm x 10 cm (~4 in. x 4 in.) – for customizing support

- 1 hot glue stick (used with a shared hot glue gun)

- 1 pre-cut paper foot template

- 1 ball for drop test (e.g. 2 oz fishing weight or rubber ball)

- 1 lb. kinetic sand— rolled into 12 x 12 x 5 cm (5 x 5 x 2 in.) square

- 1 meter stick

- 1 ruler

- 1 Student Worksheet per student

- 1 sheet of graph paper or a digital graphing tool

- 1 sheet of poster paper or half a trifold board

For the entire class to share:

- multiple hot glue guns and extra hot glue gun glue sticks

- scissors

- markers, colored pencils, and other poster supplies

Multimedia/Research Resources:

- slide deck on foot conditions and orthotic solutions (teacher-created)

- articles about foot conditions:

- Plantar Fasciitis Article

- Morton’s Neuroma Article

- Achilles Tendonitis Article

- Bunions Article

- Flat Feet Article

- Introduction Slides

- Foot Cutout Template

- Manufacturing Wrap-Up Slides

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/clem-3005-sole-survivors-energy-orthotics-activity] to print or download.Pre-Req Knowledge

Students should:

- Have a basic understanding of kinetic energy and how it relates to motion, including the concepts of mass, speed, and force.

- Be familiar with measuring length accurately using a ruler and possess basic graphing skills, such as plotting data points and interpreting graphs.

- Have some basic experience with designing simple prototypes or models, as well as the ability to follow step-by-step experimental procedures and record observations carefully.

Introduction/Motivation

I want you to imagine standing on your feet for 10 hours a day. Maybe you’re working in a factory, a hospital, a warehouse—or even at an amusement park. By the end of the day, your legs ache, your heels are sore, maybe your arches feel like they’re collapsing. Can you picture it?

That kind of pain isn’t just annoying—it can lead to injuries, chronic pain, or time off from work. That’s a real-world problem that engineers solve. In fact, companies like BMW in South Carolina hire biomedical engineers to create special shoe inserts, or orthotics, to protect their employees’ feet and joints. What we’re going to do is step into the shoes—pun intended—of those engineers and design a better solution.

Today, you’ll pick a real medical issue that affects the feet. It might be flat feet, plantar fasciitis, or bunions—these are all conditions people struggle with daily. Then, you’ll design a custom orthotic shoe insole using different foam materials to support that condition. After that, we’ll test how well your design protects from impact using a pressure test.

This is where science and engineering overlap. You’re going to use physics—kinetic energy, motion, impact force—and engineering design to solve a medical problem. Your goal is to make a product that’s not only functional, but also something that a doctor might actually want to use.

Procedure

Background

Kinetic Energy Summary

Kinetic energy is the energy an object has because it is moving, and it is calculated using the formula KE = ½ × mass × speed². This formula shows that an object’s kinetic energy depends on both its mass and its speed, but speed has a much bigger effect because it is squared—doubling the speed makes the kinetic energy four times larger. The mass contributes more directly: Heavier objects have more kinetic energy if they move at the same speed as lighter ones. The ½ comes from the physics of how forces accelerate objects. Altogether, the formula tells us that the energy of motion increases with how much matter an object has and increases rapidly as its speed increases.

Speed Increases With Height

When an object is dropped, gravity pulls it downward and causes it to speed up as it falls. The higher the object starts, the more time gravity has to accelerate it, so its speed is greater by the time it reaches the ground. Because kinetic energy depends on speed—and speed is squared in the kinetic energy formula—the object’s kinetic energy becomes much larger when it is dropped from a greater height. In other words, a higher drop gives the object more time to gain speed, and that increased speed results in significantly more kinetic energy when it reaches the bottom.

Cushioning Materials

Cushioning materials such as foam reduce force by increasing the time it takes for an object to come to a stop and by spreading the impact over a larger area. When something hits a surface, the force depends on how quickly its momentum changes—if the stopping time is very short, the force is large. Foam compresses and slows the object down more gradually, increasing the stopping time and therefore reducing the force. At the same time, cushioning materials distribute the pressure across a larger area instead of letting it concentrate in one spot. This helps protect both the object and the surface from damage. These ideas show how engineering design uses physics principles: By understanding motion, force, and impact, engineers can choose or design materials that make collisions safer and reduce the risk of injuries or damage.

Note to the teacher: Students may not have prior experience with kinetic energy or how it is calculated. Before the testing, take time to explain the formula for kinetic energy: Kinetic Energy = ½ × mass × speed². Be sure students understand that speed increases with the height of the drop due to gravity, which means the kinetic energy of the falling object increases as it is dropped from higher up. You can demonstrate this with simple examples (like dropping the same ball from two heights) before the formal experiment. Also, be prepared to explain how cushioning materials (e.g., foam) reduce force by increasing the time of impact and distributing pressure, which connects engineering design to physics principles.

Before the Activity:

- Gather and organize materials by group (see Materials section).

- Print:

- 1 Student Worksheet (includes design sketching space, data collection table, and graph templates) for each student

- 1 foot issue article from the Attachments section (either 1 per student or 1 per group, depending on how you plan to distribute the foot conditions)

- 1 Foot Cutout Template for each group

- Portion kinetic sand into containers (approximately shoe box sized), one per group of students.

- Set up drop stations with a meter stick for height measurement.

- Prepare hot glue guns and extension cords for safe group use.

During the Activity:

Day 1: Ask, Research, Imagine, and Plan

Ask

- Begin by leading a class discussion of overall shoe comfort.

- Write this overarching question on the board: “What do you think makes a shoe comfortable or supportive?”

- Ask students if they have ever worn a pair of shoes that hurt their feet, and if so, what that felt like.

- Give students a minute or two to think about their answers before sharing their thoughts with the class.

- Write student answers on the board.

- Ask students why they think their foot hurt in that spot in the bad pair of shoes, and what kind of material(s) or support or redesign of the shoe might have helped.

- Give students a minute or two to think about their answers before sharing their thoughts with the class.

- Write student answers on the board.

- Ask students to think about real-world problems that could arise from long periods of standing, especially in workplaces like hospitals and factories.

- Give students a minute or two to think about their answers before sharing their thoughts with the class.

- Write student answers on the board.

- Display and read through Slides 2 and 3 of the Introduction Slides, focusing on the importance of orthotics and introducing the idea of custom insole design.

- Go over the parts of the foot using Slide 4.

- Present the Engineering Solutions case study on Slide 5.

- Review the physics of kinetic energy on Slide 6.

- Present the engineering design challenge: You and your team will act as biomedical engineers to design, build, and test a custom orthotic shoe insole that helps reduce pain and prevent injury for people who have specific foot conditions such as flat feet, plantar fasciitis, or bunions.

Research

- Hand out the foot condition articles. Ideally, each group or pair should have a different condition.

- Give students time to read about their condition and to think about what the patient with that condition needs in a shoe.

- Optional: Give students time to research their condition and existing solutions.

- Hand out one Student Worksheet to each student.

- Have each group answer the first three questions of Part 1: Research and Design.

- Before moving on, give each group five minutes to discuss their findings and conclusions about their researched foot condition.

Imagine

- Show students Slide 7 and go over the steps of the engineering design process.

- Introduce the materials available for building orthotic prototypes.

- Show Slide 8 with the foam types and materials science.

- Using their Student Worksheet, instruct students to sketch the basic outline of an insole with foam density zones labeled to address their assigned condition.

- Wrap up the session by having each group share their foot condition challenges.

Day 2: Create

- Describe how students will test their orthotic prototype using Slide 9.

- Give each group a Foot Cutout Template.

- Have one student in each group cut out a paper foot template (size-matched) and trace it onto medium-density foam.

- As a team, have each group review the foot issue they are solving and complete their orthotic build:

- Cut shapes from soft or firm foam to match their design.

- Use hot glue to attach additional foam zones to the medium-density base.

- If some groups finish early, have students write a short note about why they placed foam in certain zones, and predict which areas of the foot their orthotic will protect most.

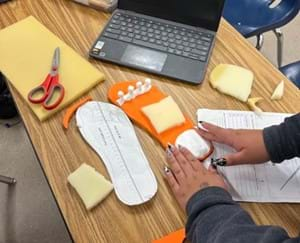

Students create their orthotic by adding different foams to parts of an orthotic to meet the needs of their foot problem.

Day 3: Impact Testing and Graphing (Day 3)

- Using Slide 10, do a quick review of kinetic energy:

- Step 1: Recall Formula

- KE = ½ m v²

- m = mass, v = speed

- Step 2: Compare Speed

- Ask: “What happens if speed doubles?”

- Answer: KE goes up 4× (because of v²).

- Step 3: Compare Mass

- Ask: “What if the mass doubles but speed stays the same?”

- Answer: KE doubles.

- Step 4: Connect to Activity

- “So, dropping the weight from higher heights increases its speed → more KE → bigger impact on the orthotic.”

Test

- Have students set up their testing areas and testing methodology.

- Place boxes of kinetic sand flat on table/tray.

- Drop weighted ball (30 g) from various heights above the kinetic sand.

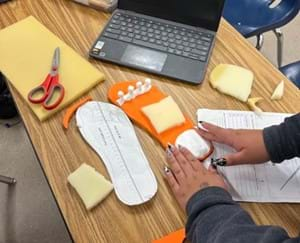

Students test their orthotic design by dropping a weight onto it from a set height.

- Give students time to measure and record the indentation depth without their orthotic prototype:

- Drop weighted ball (30 g) from 30, 60, 90, 120, 150 cm.

- Measure indentation depth (mm) and record on worksheet.

- Re-fluff sand between drops.

- Repeat with orthotic on top of sand and record data on their Student Worksheets.

Students measure the impact depth after dropping a weighted ball, simulating foot pressure with and without an orthotic insert.

Graph and Analyze

- Go over data graphing on Slide 11.

- On the worksheet, have each group:

- Create one graph for the sand only.

- Create one graph for the sand with the orthotic. (Note: This graph will have two lines for the different areas of foam, so students should use different colors.)

- Have students answer the questions in Part 4, comparing their results to determine the effectiveness of their orthotic prototype.

Improve

- Have each group determine what they would improve on their orthotic prototype, and why.

- Optional: If time permits, let students redesign/modify their orthotic prototype and then test their redesigned product.

Day 4: Poster Creation and Career Connection

- On the final section of the Student Worksheet or on separate poster paper, have each group or each team member design an advertisement for their custom orthotic that includes a labeled sketch, description of who it helps, and a claim supported by data.

- Conduct a poster gallery walk and class discussion as time allows.

- Use the Assignment Rubric to assess student learning.

- Optional: Present the Manufacturing Wrap-Up Slides to connect projects to real manufacturing careers.

Vocabulary/Definitions

graph: A diagram that represents data or values, showing the relationship between variables, usually on an x-and-y axis.

impact: The action of one object coming forcibly into contact with another.

kinetic energy: The energy that an object possesses due to its motion; defined as ½ Mass x Velocity^2.

orthotic: A device used to support, align, prevent, or correct deformities or to improve the function of movable parts of the body, such as shoe inserts for foot support.

prototype: An initial or preliminary version of a device or product from which other forms are developed or copied.

Assessment

Pre-Activity Assessment

Class discussion: Start the activity with a teacher-led discussion to activate students’ prior knowledge and curiosity. Ask open-ended questions such as:

- What kinds of problems do people have with their feet? (Possible answers: pain, flat feet, bunions, tendonitis)

- How do you think a special shoe insert or orthotic might help with these problems?

- What happens to an object’s speed and energy when you drop it from different heights?

- How could we measure the impact force without special tools?

Listen carefully to students’ answers to identify misconceptions and tailor explanations during the lesson.

Activity Embedded (Formative) Assessment

Rough Design Sketches: As students work through the project, monitor their choice of foot condition and reasoning for orthotic design elements. Review their rough sketches and placement of foam materials.

Data Collection: Observe data collection procedures for accuracy in measuring indent depth at different heights, with and without orthotics. Guide students as they graph their data and analyze trends in the Student Worksheet. Ask guiding questions such as:

- How does your orthotic design address the foot problem you researched?

- What patterns do you notice in the impact measurements?

- Why do you think the orthotic changed the depth of the indent?

Post-Activity (Summative) Assessment

Reflection Questions: Students complete the embedded reflection questions on the provided Student Worksheet that prompt them to:

- Explain how kinetic energy relates to the depth of the indent in the sand.

- Describe how their orthotic design affected impact forces.

- Reflect on what they learned about engineering and designing for real-world problems.

- Utilize reporting skills to present their findings like a real researcher would.

Troubleshooting Tips

Potential Issue: Ball doesn’t make a visible indent in the sand.

Solution: Ensure the sand is soft, fluffed, and thick enough (minimum 5 cm deep).

Backup Plan: Use a heavier ball (e.g., small hand weight or metal fishing weight).

Potential Issue: Foam orthotic doesn’t noticeably change impact depth.

Solution: Emphasize thoughtful design—placement of softer vs. firmer foam matters. Have students revise their insole based on results.

Potential Issue: Students have difficulty with graphing.

Solution: Model one graph as a class first. Provide a partially filled-out graphing template to guide them.

Potential Issue: Kinetic sand gets compacted quickly and is not a uniform stiffness throughout.

Solution: Add water to kinetic sand to help keep the tension more uniform. Sand can also be dropped into the boxes through a grate to ensure uniformity of initial compaction.

Activity Extensions

- Students can research real-world manufacturing careers related to biomedical engineering and present their findings.

- Incorporate a guest speaker (orthotist or biomedical engineer) or video about how foot orthotics are designed and tested in the real world.

Activity Scaling

For lower grades (or students who need more support):

- Simplify the engineering design process by focusing on one design iteration rather than multiple redesigns.

- Reduce the math required by providing a pre-drawn graph or letting students focus only on measuring and recording results.

- Pre-cut foam pieces or give templates for making the orthotics, so students can focus on testing and understanding the results.

For older / advanced students:

- Add multiple design and redesign steps for students to iterate and justify improvements.

- Require students to graph their data and include trend lines, error bars, or statistical averages.

- Incorporate calculations of kinetic energy (using KE = ½mv²) and force/pressure formulas (F = mv/Δt, P = F/A).

- Ask students to compare experimental results with theoretical results, deepening connections between math and engineering.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students explore the basic physics behind walking, and the design and engineering of shoes to accommodate different gaits. They are introduced to pressure, force and impulse as they relate to shoes, walking and running. Students learn about the mechanics of walking, shoe design and common gait misal...

During this activity, students look at their own footprints and determine whether they have either of the two most prominent gait misalignments: overpronation (collapsing arches) or supination (high arches).

References

Next Generation Science Standards: For States, by States. National Governors Association Center for Best Practices & Council of Chief State School Officers, 2013. The National Academies Press, https://www.nextgenscience.org.

Bus, Sicco A., et al. “Plantar Pressure Relief in the Prevention of Diabetic Foot Ulcers: A Randomized Controlled Trial.” Diabetes Care, vol. 39, no. 10, 2016, pp. 1804–1812. American Diabetes Association, https://doi.org/10.2337/dc16-1284.

U.S. Bureau of Labor Statistics. Occupational Outlook Handbook: Industrial Engineers and Medical Equipment Technicians. 2024, https://www.bls.gov/ooh.

National Institute of Standards and Technology. Advanced Manufacturing National Program Office. 2022, https://www.nist.gov/advanced-manufacturing.

Copyright

© 2025 by Regents of the University of Colorado; original © 2024 Clemson UniversityContributors

Faith Kutzer; Dr. Marian Kennedy; Dr. Kris Frady; Dr. John Desjardins; Isabella Deangelo; Hannah Ullinger; Elizabeth Hopkins; Dr. Mark JohnsonSupporting Program

Research Experience for Teachers (RET), ClemsonAcknowledgements

This digital library content was developed by the Engaging and Enabling Teachers through Advanced Manufacturing Research RET Site at Clemson University under National Science Foundation grant number 2206962. However, these contents do not necessarily represent the policies of the NSF and you should not assume endorsement by the federal government.

Last modified: December 23, 2025

User Comments & Tips