Summary

Student teams design and build shoe prototypes that convert between high heels and athletic shoes. They apply their knowledge about the mechanics of walking and running as well as shoe design (as learned in the associated lesson) to design a multifunctional shoe that is both fashionable and functional.

Engineering Connection

An amazing amount of engineering goes into the design of shoes. Shoes must withstand a multitude of forces, stresses and strains on a daily basis and withstand them for the life of the shoe. The ability of a shoe to convert between different functions is a potential solution to the problem of high heels being uncomfortable to wear for extended periods of time, difficult to drive in, and causing ankle, foot and hip injuries.

Learning Objectives

After this activity, students should be able to:

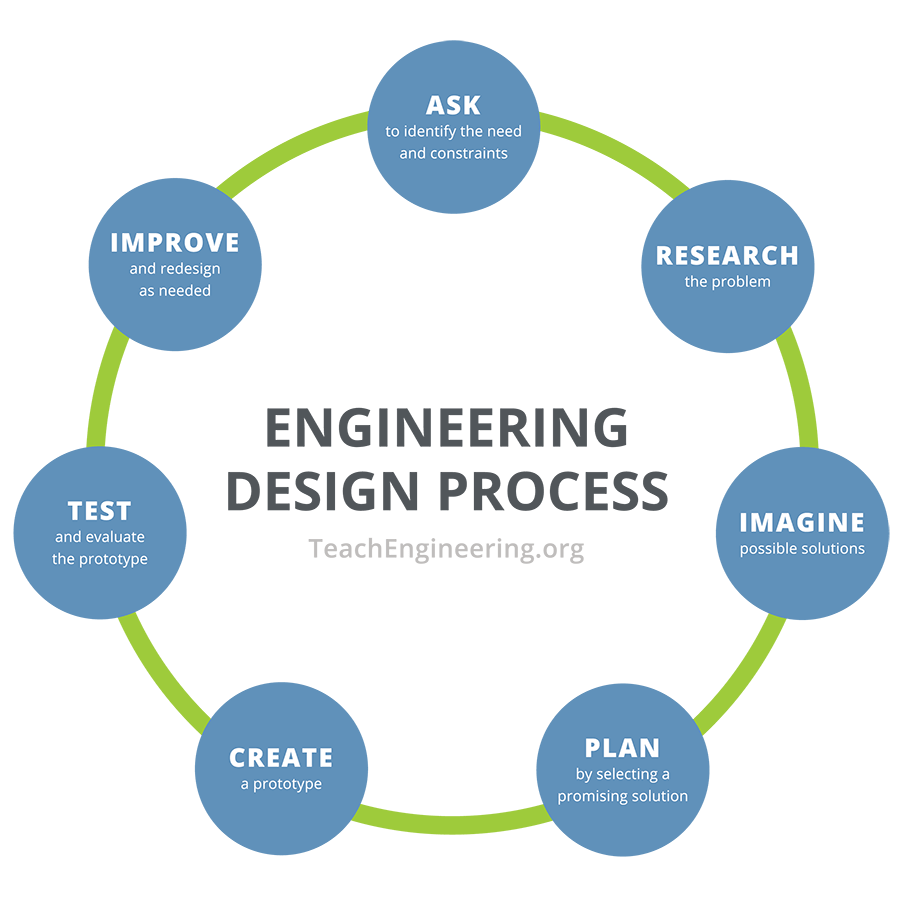

- Identify the different parts of the engineering design process.

- Identify the different parts of the walking and running gaits.

- Explain how forces on different parts of the foot increase and decrease while walking or running, and how a shoe is built to accommodate these forces.

- Explain the difference between over and underpronation, and how to fix gait misalignments with orthotics.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

Common Core State Standards - Math

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Solve linear equations and inequalities in one variable, including equations with coefficients represented by letters.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Reason quantitatively and use units to solve problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Engineering design is influenced by personal characteristics, such as creativity, resourcefulness, and the ability to visualize and think abstractly.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

A prototype is a working model used to test a design concept by making actual observations and necessary adjustments.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Determine the best approach by evaluating the purpose of the design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Colorado - Math

-

Solve linear equations and inequalities in one variable, including equations with coefficients represented by letters.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Reason quantitatively and use units to solve problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Colorado - Science

-

Newton's laws of motion and gravitation describe the relationships among forces acting on and between objects, their masses, and changes in their motion – but have limitations

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Gather all materials in advance of the activity and allow students to choose from the pre-selected materials as they design. Alternatively, have students compile a materials list within a set budget after the research phase of the design process, and buy exactly what they request. Materials are available at hardware, office supply and fabric/craft stores.

Note: An infinite number of materials can be used for this activity. The wider the selection of materials available, the more elaborate and creative student shoe designs can be. Feel free to add anything to the supply list that looks interesting or useful. Other optional materials might include: balsa wood, foam, zippers, etc.

Each group needs:

- foam core board, 8-in x 11-in (20-cm x 28-cm) size (available at hardware and office supply stores)

- thin rubber sheets, 7-in x 11-in x 0.25-in (18-cm x 28-cm x .64-cm) size (look in the plumbing section of a hardware store)

- bendable, flat metal strip for support of high heel sole, 1-in x 6-in x 0.1-in (2.5-cm x 15-cm x .25 cm)

- wooden dowels for shoe heel, 1-3-in (2.5-cm - 7.6-cm) long, of varied thicknesses

- ½-in (1.27-cm) hinges

- material for the body of the shoe (look in the fabric store scrap pile)

- shoe laces

- buckles

- button clasp

- Velcro

- other types of fasteners

- butcher block paper and pencils, for brainstorming ideas and design sketching

- Static Forces Worksheet, two per group

For the entire class to share:

- scissors

- needles and thread

- duct tape

- epoxy

- rubber cement

- hot glue gun and glue sticks

- screwdrivers and screws

- drill

- (optional) computer with CAD program

- (optional) video camera to film group 30-second shoe commercials

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_convshoes_lesson01_activity1] to print or download.Introduction/Motivation

How many pairs of shoes do you have? Could you name some of the different types of shoes that you have? (Listen to student descriptions.) Wouldn't it be nice if a pair of dress shoes with heels could double as a pair of running shoes? You could wear a nice pair of shoes to school and then you wouldn't need to bring an extra pair of running shoes for gym. It would decrease the amount of closet space needed for your shoes by a factor of two.

Designing a shoe is a complex process during which several factors must be considered. As an example, the pressure that a stiletto heel exerts on the ground while walking is greater than that of an elephant walking! And the heel also experiences a great deal of torque during the heel strike phase of the stride. A high-heel shoe must be designed to withstand these forces while also providing support for the foot since the entire foot never touches the ground at once. It generally requires a stiff sole to maintain the shape of the shoe and prevent the foot arch and entire shoe from collapsing during the midstride phase.

A running shoe, on the other hand, must be able to withstand the impact of hitting the ground every time the runner takes a stride and it must do so without slipping, so the runner can propel him/herself forward. Running shoes must provide enough support to pad the foot and prevent injuries, while still being flexible enough to allow the foot to flex through the stride.

What would happen if the wearer of the shoe had a knee injury resulting from either high arches or collapsing arches? Orthotics are often used to fix common gait misalignments caused by overpronation (sometimes known as collapsing arches) or supination (sometimes known as high arches). Orthotics can be designed and placed into a shoe to create a straight line between a person's ankle, knee and hip, fixing many common knee and foot injuries.

Is it possible to create a shoe that converts between these two very different functions while fixing a gait misalignment? That's our engineering project. Let's get designing.

Procedure

Background

This open-ended activity can be done in several hours, or extended much longer. It is important to have several interim milestones for students to aim for within the engineering design process to ensure progress is being made.

Engineering Design Process

The engineering design process (sometimes called the engineering design loop) is a set of steps that engineers use to design and build a product. For this project, the steps are as follows:

- Ask: Identify the Need and Constraint: High-heeled shoes are a societal norm but cause many back, knee and ankle problems for those who wear them. If a high-heeled shoe was able to convert easily to a shoe without a heel, then the wearer could switch between the two styles when appropriate (such as when driving a car), increasing comfort and reducing foot injuries.The foot's position in a high-heeled shoe is detrimental to leg alignment and should not be used for extended periods of time.

- Research the Problem: Gather information: Some things to consider: Has anyone else made a "convertible shoe?" How much padding is needed to provide support to an athletic shoe? How is padding distributed on the sole of an athletic shoe? How high can a heel be before causing health problems? Does the shape of the toe box of a shoe matter?

- Imagine Possible Solutions: Generate concepts: During this brainstorming phase, all ideas are good ideas. Encourage wild ideas. Do not judge ideas (at this stage). Write down all ideas. For example, ways to make a shoe convert between a high heel and an athletic shoe might include: a heel that can be turned under the shoe and stowed, a heel that can be removed completely, and a heel that can telescope into itself. These are just a few ideas.

- Plan: Select the most promising concept: Select the most promising concept: Each project has certain constraints. This project is constrained by materials, time and people. The most promising solution fulfills all the requirements while working within the constraints.

- Create a prototype: A prototype is a working version of the final product. It is used to demonstrate the concept, and for this project, will be the final deliverable product. Prototypes are further used as a model to produce the final product.

- Test and Evaluate the prototype: The prototype must fulfill the requirements decided upon at the beginning of the project. For this case, the shoe must be wearable and convert between a high heel and an athletic shoe. Evaluate test results: Did it work? Does the heel retract? Can the shoe hold the weight of a person? Is it attractive?

- Improve: Redesign as Needed: Most engineers go through the design loop several times to reach a final product. If time is a limited, then students can describe what they would change if given more time. If time permits, students can do a redesign and change certain aspects of their shoe to make it better.

Before the Activity

- Review with students the 7 steps of the engineering design process.

- Decide on your approach to the activity. Either: 1) Gather a pre-selected supply of construction materials in advance of the activity from which students incorporate as they design, or 2) Have students compile a materials list within a set budget after the research phase of the design process, and buy what they request.

- Make two copies of the Static Forces Worksheet per group — one to complete at the beginning of the project, using the shoes from one team member, and another to complete at the end of the project using the team's prototype shoe.

- As needed, print out the attached Engineering Design Process Graphic for reference.

With the Students - Shoe Design

- Divide the class into teams of three or four students each.

- To make sure students understand the relationship between force, pressure and surface area, have each team complete the Static Forces Worksheet using one team member's shoe.

- Starting with the beginning of the design process, recognize a need: Identify a problem. For example, most shoes have only a single function. Or, most athletic shoes are not appropriate for a dressier occasion. Alternatively, discuss the health effects of wearing high-heeled shoes and brainstorm situations in which being able to remove heels quickly would be beneficial (such as driving a car, walking to the bus or sitting at a desk). As necessary, go through the steps as they apply to this project, as described in the Background section.

- As a class, brainstorm features required for both a high-heel shoe and an athletic shoe. A high heel needs structural support under the arch, as well as a sturdy way to keep the heel attached. An athletic shoe needs a flexible sole and a fastening system so the wearer can tighten the shoe.

- Working in their engineering design teams, have students compare their shoes for 10 minutes. Have them write down differences in construction and support features such as rigidity, materials used, fastening devices, shape, etc.

- Have each group hold a 15-minute brainstorming session during which they list all the possible features their convertible shoes might have and ways to convert between the two styles. Give each group a large sheet of butcher paper and encourage them to write down all ideas that come up. The conversion mechanism might be a hinge that folds the heel away or some way to easily remove the heel and its sole support.

- (If requiring students to use a pre-selected supply of materials, show students these materials at this time.) Have students spend 20-30 minutes designing their shoe on paper, working from the brainstorming session ideas. If possible, have them make CAD drawings of their designs.

- Design Peer Review: Have each group present their designs to the class. Make sure they explain key shoe features that make it a good athletic shoe and a good high heel. Make sure they explain the conversion mechanism clearly. Allow time for the other teams to critique the presenting group's design and offer feedback and suggestions for improvement.

- (If buying supplies that students specify, have them make a materials buy list at this time.)

With the Students - Building Shoes

- Have each group retrieve the materials required for their shoe design (either from the pre-selected materials provided or from supplies the instructor purchased from their buy list.)

- Allow about 60 minutes for students to build the soles of the shoes. For example, they might be made of foam core board cut to the shape of a foot and covered with a thin rubber sheet for traction. Create creases in the foam core board to correspond to the foot, toe and arch joints, which allows the shoe to take on a high-heeled shape.

- Next, have students build the removable or retractable heel. For example, the heel might be made of wooden dowels and attached with a hinge so it swings under the shoe and into a slit in the rubber base when not in use, or it can be removed completely using a button clasp. Allow 30-90 minutes, depending on the method used to stow or remove the heel.

- Use the flat metal piece to create the shape of the high heel. Attach it to the flexible sole of the shoe using Velcro and hot glue so it is removable. Allow 30 minutes for this step.

- Give students at least two hours to finish their shoes (or extend longer, depending on the intricacy of their designs). At this stage, have students build the upper part of the shoe using fabric that is attached by using hot glue or sewing. Have students add a fastening system to the shoes, possibly using laces, Velcro or buckles. Have students accessorize their shoes to make them unique.

With the Students - Marketing

- Have students write scripts for 30-second commercials selling their shoes, highlighting the technical features and customer benefits. Perform or video-tape the commercials to show the entire class.

- Have teams complete the Static Forces Worksheet for their prototype shoes, including calculating the pressures and forces experienced by their shoes in the different configurations.

- Conclude by conducting a class critique of each group's shoe prototypes. Have each group explain the unique features of each style of their shoe, as well as the conversion mechanism to switch between them. If this was a real project and they had more time, what improvements would they make? Remind students that real-world engineers cycle through the engineering design process many times before they have a completed design, ready to manufacture.

Vocabulary/Definitions

force: Pushes or pulls; anything that causes an object to accelerate or change direction.

impulse: Average force x change in time or change in momentum. A measure of how "hard" a shoe hits the ground.

orthotic: An insert placed inside a shoe to correct either overpronation or supination.

overpronation: Excessive rolling inward movement of the foot when walking or running. Predisposes lower extremity injuries (such as knee injuries). Causes heavier wear on shoes on the inner margin. Collapsing arches while walking.

pressure: Force per area.

supination: A rotation of the foot and leg in which the foot rolls outward with an elevated arch so that in walking the foot tends to come down on its outer edge. Leads to shoes wearing on the outer edge, and knee injuries. High arches. The opposite of pronation. Same as underpronation.

Assessment

Pre-Activity Assessment

Force and Pressure: Have students complete the Static Forces Worksheet using one team member's shoe, to ensure they understand the relationship between force, pressure, and surface area. (This same worksheet may have already been completed if the associated lesson was conducted.)

Activity Embedded Assessment

Design Peer Review: Have group present their designs to the class and ask for feedback. Have them explain key features in their shoes that make them good athletic shoes and good high heels. Make sure they explain the conversion mechanisms clearly.

Post-Activity Assessment

TV Time: Have group write scripts and film (or perform) 30-second commercials selling their shoes. Make sure they highlight the key engineering features and customer benefits of their shoes.

Pressures: Have students calculate the pressures and forces experienced by their shoes in the different configurations. Hand out another Static Forces Worksheet for each team to complete the calculations for their prototype shoe.

Redesign: Conduct a class critique of each group's shoe prototypes. What improvements would they make in the next prototype version?

Making Sense: Have students reflect about the science phenomena they explored and/or the science and engineering skills they used by completing the Making Sense Assessment.

Safety Issues

- Provide supervision when students use power tools and hot glue.

Troubleshooting Tips

Gluing is always an experimental art. Be sure to have a wide variety of adhesives or other attachment options available.

Students tend to get caught up on various steps of the design process such as research or design. Often, students need to be forced to move from these phases into the prototype construction phase.

Activity Extensions

Have teams make additional, improved prototypes of their shoe designs.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students explore the basic physics behind walking, and the design and engineering of shoes to accommodate different gaits. They are introduced to pressure, force and impulse as they relate to shoes, walking and running. Students learn about the mechanics of walking, shoe design and common gait misal...

During this activity, students look at their own footprints and determine whether they have either of the two most prominent gait misalignments: overpronation (collapsing arches) or supination (high arches).

Students use the engineering design process to solve a real-world problem—shoe engineering! Working in small teams, they design, build and test a pair of wearable platform or high-heeled shoes, taking into consideration the stress and strain forces that it will encounter from the shoe wearer.

Students act as biomedical engineers and follow the engineering design process to create and test custom orthotic insoles. They begin by asking questions to learn about foot-related medical problems, such as plantar fasciitis and flat feet, and identify how orthotics can help reduce pain or pressure...

Copyright

© 2010 by Regents of the University of Colorado.Contributors

Eszter HoranyiSupporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under a grant from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education and National Science Foundation GK-12 grant no. 0338326. However, these contents do not necessarily represent the policies of the Department of Education or National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: October 23, 2020

User Comments & Tips