Quick Look

Grade Level: 7 (6-8)

Time Required: 1 hour

Expendable Cost/Group: US $1.00

Group Size: 2

Activity Dependency: None

Associated Informal Learning Activity: Fancy Feet! Stress & Strain Forces in Shoe Design

Subject Areas: Science and Technology

NGSS Performance Expectations:

| MS-ETS1-1 |

| MS-ETS1-2 |

Summary

Students use the engineering design process to solve a real-world problem—shoe engineering! Working in small teams, they design, build and test a pair of wearable platform or high-heeled shoes, taking into consideration the stress and strain forces that it will encounter from the shoe wearer. They conclude the activity with a "walk-off" to test the shoe designs and discuss the design process.

Engineering Connection

Today, thousands of different types of shoes exist in our world and just as many engineers are working to develop new styles and improve existing designs. Engineers consider many variables when designing shoes—material type for durability and function, anticipated shoe stresses and strains, the health and safety of the shoe wearer, and the shoe's aesthetics. Engineers often work with podiatrists to design high-tech shoes that are safe, comfortable and stylish! Mechanical engineers apply principles of physics to analyze, design and manufacture mechanical systems, including new shoes. Materials engineers—specialists in the structure of materials and their properties—select and design the best combinations of materials for specific shoe purposes.

Learning Objectives

After this activity, students should be able to:

- Explain how engineers are involved in the analysis and design of contemporary shoe technology.

- List different aesthetic and structural considerations involved in shoe design.

- Follow the steps of the engineering design process to analyze, model and optimize a problem.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Make two-dimensional and three-dimensional representations of the designed solution.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Colorado - Math

-

Direct and indirect measurement can be used to describe and make comparisons.

(Grade

8)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- paper and markers, or colored pencils, for design sketches

- foam core board; available at hardware, art, craft, hobby and office supply stores in 32-inch x 40-inch [81 cm x 102 cm] sheets; each team needs a half a sheet at a minimum; a full sheet per group is optimal to take cutting or design iterations into account

- markers, for writing on foam core

- Xacto™ knife, for cutting foam core, plus extra new blades, as necessary

- rulers; metal edge preferred

- glue gun and glue sticks

- assorted decorating materials such as ribbon, markers, paint, buttons and construction paper

- Foam Core Tips

- Fancy Feet Steps

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_feet_activity1] to print or download.Introduction/Motivation

Today we are going to embark on an exciting engineering adventure as we create shoes! First, let's talk about shoes. Everyone, hold up one foot! Wow, what a lot of different shoe styles in this room, all suited for different purposes. (Ask a few students to describe the functions of their shoes. Are they best for running, skateboarding, keeping the foot cool or warm [such as sandals or boots] or just to protect the foot and look stylish?)

Most of the time, we put on our shoes without thinking about who designed the shoe and why a particular design was created. You might not realize that many engineers are involved in developing new shoe styles and improving existing designs. Shoe engineers design, build and test shoes before they reach the marketplace to be sold to you. Today, you will see what it is like to follow the steps of the engineering design process to build and test your own pair of shoes!

Our design challenge today is to create shoes with a heel. Just to clarify—heeled shoes are not just worn by girls! Cowboy boots are heeled shoes and some hiking shoes have thick platforms. Heeled shoes are generally defined as shoes that raise the heel of the wearer's foot higher than the toes. Platform shoes are similar except that they raise both the toe and the heel equal amounts. Both types require a tremendous amount of engineering to make sure that the shoe does not cause too much stress on the foot. Has anyone ever heard someone say that they love to wear high heels but cannot stand the pain? One problem with heeled shoes is that they shift the foot forward, transferring more weight to the ball of the foot, which can be an uncomfortable way to walk and cause blisters, corns and bunions. Ouch!

Even though a little pain won't stop most people from wearing heeled shoes, engineers are always looking for ways to improve the quality of people's lives. And they do! Engineers often work with foot doctors to design high-tech shoes with special materials, insoles and air pumps so they are comfortable, safe and stylish! (Optional: Read to students the attached news article, Alumni Make Heels for Pain-Free Fashion in the Shoe Engineer Story.)

Today, advancements in shoe engineering have produced sport shoe inserts with interchangeable spring heels designed for specific activities. High-spring inserts are designed for basketball or jumping sports. Medium-spring inserts are used for aerobic sports and dancing. Low-spring inserts are used for walking and jogging. When you are designing your own shoes, think about the qualities and features you want your shoe to have. If you could design any type of shoe, what would you design? (Next, lead the pre-activity assessment as described in the Assessment section, in which students describe and draw their "dream shoes.")

Who knows something about the engineering design process? This is a set of steps that engineers go through when they develop new or improved products. Can you think of some of the steps an engineer may need to complete when designing something? Well, first they must clarify the problem or need. Then, they brainstorm creative ideas and solutions to that problem or need. Next, they analyze those ideas and select the most promising one, and draw or communicate the design plan for the idea. Finally, they build a prototype or model of the design and evaluate whether or not that design is successful. The design process continues, in a cyclical fashion, as engineers keep testing and improving the design to make it the best it can be.

Today, we will create our shoes using foam core board for the shoe structure and decorating materials such as paint, ribbon and buttons. Each engineering team will receive a certain amount of these materials. Your challenge is to figure out how to create a pair of wearable shoes from the given amount of supplies. In real life, engineers always work within limitations, such as budget, time and materials. Engineers call these "design constraints" and the concept applies to more than just engineering. What are some instances in your own life in which you are faced with constraints? (Possible answers: Allowance, amount of free time, an injury.) Fortunately, one of our strengths as humans is our ability to be innovative and resourceful. So, be creative when designing your shoes! Your finished product should be a pair of shoes that can support your weight while walking. At the end of our design challenge, we will have class "walk off" to show off our new shoes!

Procedure

Background Information

As simple as a shoe might seem, it is actually a complex structure requiring a significant amount of engineering. Basically, a shoe is a system comprised of different parts that are sewn, stuck or welded together before being shaped and attached to a sole. In today's world, thousands of different shoe designs exist and just as many engineers are developing new shoes and improving existing designs. When designing shoes, engineers consider all sorts of variables: suitable materials, anticipated forces the shoe will encounter, shoe wearer's health and safety, as well as aesthetics (how it looks). Often, engineers work with podiatrists and kinesiologists (specialists in human movement) to design safe and comfortable shoes, and with fashion designers to create stylish and marketable products.

Materials: For centuries, leather has been the primary material for shoes. However, due to the work of many engineers (especially materials and chemical engineers), we now fabricate shoes using synthetic (human-made) materials. Leather is still preferred by some shoe-wearers due to its comfort and durability. A limitation of leather is that it cannot be obtained in endless rolls, which makes it less suitable for factory production in the footwear, glove and upholstery industries. Also, the material properties of leather tend to change in different conditions, and it is susceptible to fungal infections.

The main types of synthetic shoe soles that have been developed include materials based on ethylene vinyl acetate (EVA) and thermoplastic rubber. For the upper part of the shoe, polyurethane-coated fabric is a popular synthetic material. Polyurethane is a type of polymer that has many uses. It is commonly used as foam insulation in refrigerators and walls, packaging materials and upholstery. In the case of shoes, a very thin coating of polyurethane is applied to a cotton base. Polyurethane-coated fabrics have become increasingly popular because the surface creases closely simulate the 'break' or folding characteristics of leather. Also, its moisture absorption and permeability properties mimic natural leather. Polyurethane is water resistant yet breathable enough to discourage stinky feet!

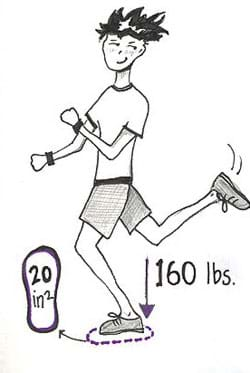

Engineering for Stress and Strain: Just like civil engineers who design bridges, a "shoe engineer" must design shoes to withstand the different forces and conditions the shoes will be exposed to during their lifetimes. A typical pair of shoes is subjected to stress exerted by the wearer during normal use. In mechanical terms, stress is defined as the amount of force per unit area. For example, for a 160-pound person jogging in a pair of shoes with a sole area (surface area that touches the ground) of 20 square inches, the runner exerts a stress of 160 pounds per 20 square inches (in2) = 8.0 psi (pounds per square inch).

A jogger exerts a compressive stress on the shoe. Compressive stress results in a material's compaction (decrease in volume). The runner also exerts a strain on the shoe by stretching the material when running. Over time, too much strain causes shoe material to break or rip (engineers call this "material failure.")

Some shoe styles, especially high heels and platforms, cause unnecessary stresses on various foot bones and joints. Over the past few decades, engineers have designed more comfortable and safe shoes while still maintaining desirable characteristics such as style, durability and affordability.

High Heels: Heeled shoes raise the heel of the wearer's foot higher than the toes. While many types of women's high-heel shoes exist, many other shoe designs have heels and are worn by both men and women, such as cowboy boots.

Some people love the look of high heels but cannot tolerate the discomfort! Standard construction of high-heel shoes creates a "ramp effect," in which the foot slants forward and down while bending the toes up. When the foot shifts forward, more weight is transferred to the ball of the foot, which can cause damage to the underlying soft tissue that supports the foot. In many high-heeled shoes, the toes become compressed, causing blisters, corns, hammer toes and bunions. Also, because high heels tip the foot forward, they put pressure on the lower back by pushing the derriere outwards and compressing the vertebrae. Many doctors advise wearing high heels as infrequently as possible and never more than 12 hours in a day.

Medical issues are certainly a hindrance to those who love to wear high heels! Recognizing that fashion trends are rarely influenced by health concerns, podiatrists and engineers have designed fashionable heels that do much less damage to the foot. Nike, a pervasive vendor of athletic shoes, apparel and sports equipment, developed an "air pump technology" that counterbalances the painful pressure caused by typical high heels by shifting the wearer's weight off the ball of the foot and back to the heel. The Nike air pump is an air bag system that uses pressurized air and a special wood pulp celluose fiber. Because it is constructed within the shoe, placed under the ball of the foot and in the heel, these high heels look no different than conventional heels! Show students other ways engineers are designing shoes to be both comfortable and stylish as described in the Alumni Make Heels for Pain-Free Fashion news article in the Shoe Engineer Story.

Platform Shoes: In contrast to high-heeled shoes, platform shoes raise both the toe and the heel equal amounts. Platform shoes are shoes, boots or sandals with thick soles, usually made of wood, cork, plastic or rubber. Because the toe and heel remain at about same level in platform shoes, wearers are less likely to suffer from the "ramp-effect" caused by high-heeled shoes. Still, platform shoes are best if designed with enough room for the toes to wiggle and a platform that is both rigid (to keep the wearer standing upright) and flexible (to absorb shock and permit some bend).

Foam Core Shoes: In this activity, students use foam core board to create shoes. The properties of foam core board are different than synthetic polymeric materials; however, foam core is sturdy and can be manipulated to create objects with bends and curves. (Refer to the attached Foam Core Tips to learn how to create cool shapes and structures using foam core.)

The soles of foam core shoes are relatively simple and can be created in a few steps:

- Shaping the sole: Trace the shape of your feet on the foam core board and cut out the shape using an Xacto™ knife.

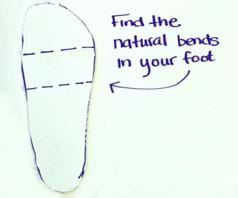

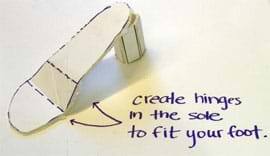

- Fitting the shoe: Mark the lines at which the sole should bend to fit your foot and create hinges in the foam core.

- Creating the lift: The heel and/or platform of the shoe requires more foam core design work, but with a little creativity, you can create all sorts of designs!

Design Considerations: The general performance requirements of a shoe include durability, high-abrasion resistance (less prone to scuffing), flexibility, dimensional stability (shoe does not shrink or spread in wear), resistance to chemical degradation, and good permeability and absorption properties.

When designing a pair of heels or platforms, remember to design the toe box with enough room for the toes to assume a normal separation. Also, heels that are too wide do not necessarily offer more stability. In fact, heels with too much width can cause unhealthy side-to-side torque to the ankles, creating additional impact on the feet. The best design for a high-heel shoe is one with a narrower width, in which the heel is kept more solidly underneath the ankle. Lastly, make sure the heel is able to support the wearer! Make the heel flexible enough to absorb some shock, but rigid enough not to bend or buckle.

Before the Activity

- Review background information, including how to create shapes with foam core. Building a pair of foam core shoes for demonstration is a good way to practice with the material.

- Gather supplies and make copies of the Foam Core Tips and Fancy Feet Steps, and/or prepare overhead transparencies of them.

- Prepare a classroom or hallway area suitable for a "walk-off" to take place at the activity conclusion. One suggestion is to have the walk-off in an area in which students from other classes can watch the activity to see how cool it is be an engineer!

With the Students

- Conduct the Introduction/Motivation section, and provide suitable background information.

- Lead students through the pre-activity assessment (see the Assessment section) in which students brainstorm their "dream shoes."

- Divide the class into teams of two students each.

- Give each team a half sheet of foam core board. Explain the engineering design challenge: To create a prototype of a heeled or platform shoe design using only a half sheet of foam core. The finished product should be a pair of shoes that can support the student's weight while walking. As an example, show students a finished pair of foam core shoes.

- Give each team a copy of the steps and tips handouts.

- As necessary, demonstrate how to create different designs using the foam core techniques described in the tips handout.

- Review the safety hazards of using Xacto™ knives and glue guns.

- Have each team generate several preliminary sketches of possible shoe designs. Remind students to recall the ideas they generated earlier (in the pre-activity assessment).

- Lead the activity embedded assessment (see Assessment section) in which each team swaps its favorite preliminary sketch with another team and provides constructive feedback.

- Once teams have finalized their designs, give them time to figure out how they will cut all of their shoe components efficiently from the half sheet of foam core board.

- Help students safely cut their shoe components from the foam core using the knives.

- Help students glue shoe components together using the hot glue guns.

- Advise students to test and modify their shoes before decorating and finishing them.

- If some students' shoes are buckling or failing when tested, help them brainstorm possible solutions. See the Troubleshooting Tips section.

- To complete the design/build portion of the activity, give students time to decorate their shoes and prepare for the "walk-off."

- Conclude the activity by leading the class in a "walk-off" to test the shoes (as described in the post-activity assessment in the Assessment section).

Vocabulary/Definitions

design constraint: Any physical, economic, social, aesthetic or time limitation imposed on the design of a solution to a technical problem.

engineering design process: A decision-making process used by engineers to create a product, structure or system. Combines an understanding of basic sciences and mathematics with available resources (material, people) to meet a desired goal.

foam core board: A strong, lightweight, easily-cut material composed of a piece of polystyrene foam sandwiched between two pieces of surface paper.

podiatrist: A person qualified to diagnose and treat foot disorders.

polymer: A long chain of small molecules joined together to create a variety of materials, including plastic and foam. Polymers can be rubbery, sticky and gooey, or rigid and hard.

prototype: A first attempt or early model of a new product or creation. May be revised many times.

strain: The deformation caused by the action of stress on a physical body. Strain is indicated by a change in size and/or shape.

stress: The measure of force per unit area within a body. Compressive stress applied to materials results in a decrease of volume.

Assessment

Pre-Activity Assessment

Dream Shoes Design: Have each student think about his/her "dream shoes." If you could design any type of shoe, what would you design? Suggest that students consider characteristics such as function, comfort, durability, flexibility, waterproof and breathable materials, style, marketability and cost. Have students create descriptions and drawings of their dream shoes.

Activity Embedded Assessment

Peer Review/Evaluating Alternatives: After students have generated several preliminary shoe designs, have each team swap its best sketch with another team. Ask teams to provide each other with constructive feedback. Is the proposed design too stylish to be practical? Does the shoe heel or platform appear to be a reasonable height? What components are provided to make sure the wearer's toes will be held in place and not be too squished?

Post-Activity Assessment

The Walk-Off/Engineering Presentation: For the "walk-off," have one person from each team walk a set distance in the team's shoes. For fun, arrange to have the walk-off in a hallway or an area in which more students can see the activity! Pose a question to each team after they have completed the walk-off (see the Investigating Questions section for ideas). Have students whose shoes were successful explain the engineering design features that encouraged safety, comfort and style. Have students whose shoes did not endure the walk-off explain what they would do differently if given the chance to improve their designs (a step in the engineering design process). Have all students name one component or structural consideration involved in shoe design.

Investigating Questions

- How do design constraints affect engineering projects? (Answer: A design constraint is a physical, economical, social, aesthetic or time limitation, requirement or boundary. In the real world, engineers work within these constraints to design products, structures and systems.)

- How would you describe somebody who is "ingenious" and "resourceful"? (Answer: An ingenious person is someone who is clever and original when inventing or constructing something. A resourceful person is able to act imaginatively and creatively, especially in difficult or restrictive situations.)

- Why is it advantageous for an engineer to be ingenious and resourceful? (Answer: Because engineers must respond to design constraints, it is important that they maximize their available resources by being clever, original and imaginative while working within in a set of constraints.)

- How can we use the engineering design process to create a pair of shoes? (Answer: We follow its cyclical steps. We first brainstorm ideas and generate a design for a pair of shoes. Once we have analyzed a design and thought about all the different circumstances that might cause the design to fail, we build prototypes of the shoes. Then we test the shoes to assess performance. We want to determine what design modifications are necessary to produce shoes that are safe, comfortable and stylish. If changes are needed, we create a new or improved design and work through the design process again.)

Safety Issues

Alert students to the safety hazards of using sharp knives and hot glue.

Remind students of the cutting safety tips described on the Foam Core Tips handout.

Troubleshooting Tips

If some students' foam core shoes collapse when worn, have them rebuild the soles and pay extra attention to the natural bend of the foot. It is common for students to make the heel portion of the sole too small, forcing more weight forward. Ideally, we want most of the weight to rest on the heel. Another idea is to have students make a shorter heel to reduce the amount of pressure on the toe box of the shoe.

Activity Extensions

Fancy Feet Promo: Have students create advertising to market their shoes. Presentations might consist of a brochure and short presentation, a catchy slogan and skit, a jingle, or even a rap or song! Encourage students to be creative while remembering that the purpose of advertising is to convince a target audience that the product is the absolute latest and greatest!

Activity Scaling

- For younger students, prepare foam core shoe components in advance. Give each group a different set of shapes and have them create their shoes without using the sharp knives.

- For older students, encourage them to create more complicated shoe designs. Assign each team to design a pair of shoes that performs a specific function. For example, "Wrangler" shoes might be similar to cowboy boots. "Summit" shoes might be designed for hikers. "Puddle Jumper" shoes might be waterproof. Provide students with a greater variety of materials (such as cardboard, foam, foil, plastic wrap, cork, etc.) from which to create these "functional" shoes. Have students discuss the compressive and tension forces in action with their shoes.

Additional Multimedia Support

Great information about engineering in everyday life at the University of Southern California's Viterbi School of Engineering website's online magazine, illumin, including an article, Walking in High Heels: The Physics Behind the Physique, (volume IX, Issue I) at http://illumin.usc.edu/81/walking-in-high-heels-the-physics-behind-the-physique/0/.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students explore the basic physics behind walking, and the design and engineering of shoes to accommodate different gaits. They are introduced to pressure, force and impulse as they relate to shoes, walking and running. Students learn about the mechanics of walking, shoe design and common gait misal...

Student teams design and build shoe prototypes that convert between high heels and athletic shoes. They apply their knowledge about the mechanics of walking and running as well as shoe design (as learned in the associated lesson) to design a multifunctional shoe that is both fashionable and function...

Students design, build and test shoes to develop new styles and improve existing designs.

During this activity, students look at their own footprints and determine whether they have either of the two most prominent gait misalignments: overpronation (collapsing arches) or supination (high arches).

References

Enders, Dave. Alumni Make Heels for Pain-Free Fashion. Published September 29, 2004. Alumni Association, Massachusetts Institute of Technology. Accessed January 14, 2008. (read about engineering design of footwear on page 6 of MIT Tech Talk, September 29, 2004 issue; or see attached Shoe Engineer Story in pdf format) http://newsoffice.mit.edu/2004/highheels-0929

High-heeled footwear. Wikipedia, The Free Encyclopedia. 3 Jan 2008. Wikimedia Foundation, Inc. Accessed January 14, 2008. www.wikipedia.org

How to Reduce Foot Pain – Comfortable High Heels – Insolia High-Heel Inserts. Science meets Sexy. HBN Shoe, LLC. Accessed April 29, 2010. (In a 1:22-minute video, inventor Howard Dananberg explains how the Insolia high-heel inserts work.) www.insolia.com/a-how-insolia-works.html

Platform shoe. Wikipedia, The Free Encyclopedia. 12 Jan 2008. Wikimedia Foundation, Inc. Accessed January 14, 2008. www.wikipedia.org

Pitz, Marylynne. Nike's Air System Slips into High Heels. Published September 19, 2006. Gazette NOW Living, Pittsburgh Post-Gazette, Pittsburgh, PA. Accessed January 14, 2008. www.post-gazette.com/pg/06262/722950-314.stm

Copyright

© 2007 by Regents of the University of ColoradoContributors

Lauren Cooper; Malinda Schaefer Zarske; Denise W. CarlsonSupporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under grants from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education and National Science Foundation (GK-12 grant no. 0338326). However, these contents do not necessarily represent the policies of the DOE or NSF, and you should not assume endorsement by the federal government.

Last modified: February 25, 2020

User Comments & Tips