Quick Look

Grade Level: 9 (8-10)

Time Required: 4 hours 30 minutes

(over three 90-minute class periods, each a week apart)

Expendable Cost/Group: US $5.00

Group Size: 2

Activity Dependency: None

Subject Areas: Chemistry, Physical Science, Science and Technology

NGSS Performance Expectations:

| HS-ETS1-2 |

| HS-ETS1-3 |

Summary

Water filtration is a key engineering concept, and in this activity students become environmental engineers as they model membranes and membrane treatments to remove scaling during water filtration. Using cheese cloth to represent a simple membrane, students soak their “membrane” in a supersaturated salt (or sugar) solution and measure how much salt (or sugar) crystallizes on their cloth. They then research and analyze different treatments they can apply to their “membranes” to reduce the scaling (crystal growth). They apply and test their chosen treatments and then hypothesize which treatment method best prevents scaling on their “membrane.”Engineering Connection

Water treatment are some of the most important technologies for the preservation of life. Environmental engineers work to create more efficient methods of water treatment in extreme situations, where if a system goes down, it would spell disaster for the humans there. One of the current best technologies is using membrane distillation to remove harmful or unwanted substances from water to make it drinkable again, however scaling on the membrane can increase the cost if left untreated. Engineers are currently working on ways to prevent the scaling from growing in the first place, delaying or hopefully even preventing the need to bring the water filtration system down for maintenance. Engineers work to develop water filtration devices that can be used in the aftermath of natural disasters where access to clean water isn't available.

Learning Objectives

After this activity, students should be able to:

- Think and outline design iteration suggestions.

- Understand the different steps of the engineering design process.

- Identify supersaturated solutions.

- Identify and discuss the differences between treatment options.

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: Analyze data using tools, technologies, and/or models (e.g., computational, mathematical) in order to make valid and reliable scientific claims or determine an optimal design solution.Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

Common Core State Standards - Math

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Use geometric shapes, their measures, and their properties to describe objects (e.g., modeling a tree trunk or a human torso as a cylinder).

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the relationships among technologies and the connections between technology and other fields of study.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

Texas - Science

-

distinguish between types of solutions such as electrolytes and nonelectrolytes and unsaturated, saturated, and supersaturated solutions;

(Grades

10 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- hot plate

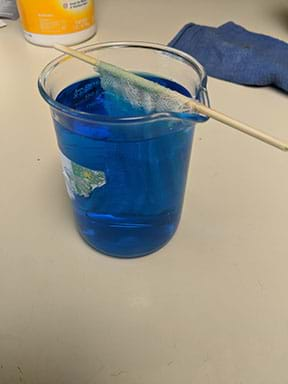

- 250 mL beaker

- 4 x 400 mL beaker

- glass stirring rod

- digital scale/balance (will need to be accurate to 0.01 g for best results)

- weigh boats (to keep solution off scale)

- 500 mL (~20 oz.) distilled water (250 mL per day – see Procedure section)

- 500 g (~20 oz.) pickling salt OR 500 g (~20 oz.) sugar (250 g per day – see Procedure section)

- teaspoon or small spoon

- skewer

- 2 pieces of 6 cm x 12 cm (~2” x 5”) cheese cloth (1 cloth piece per day – see Procedure section)

- 2 potholders

- apron for each team member

- gloves for each team member

- safety glasses for each team member

Optional (these can improve aspects of the activity, but are not necessary)

- aluminum foil (to cover experiments, prevent dust)

- clothespins (if needed to securely attach cloth to skewer)

- paper clips (if needed to ensure cloth hangs straight down)

- mason jars (used if students are taking their experiments home)

- towel (to wrap around 400 mL beaker to help the solution cool slowly and improve crystal growth; only needed for a few hours)

For the entire class to share:

- sticky notes

- pack of 20 white candles (sized 4-inch tall x ½ inch diameter, or similar)

- container of petroleum jelly skin protectant

- 500 mL Calcium Chloride Solution, 0.1 M Aqueous, Laboratory Grade (https://www.flinnsci.com/calcium-chloride-solution-0.1-m-500-ml/c0234/)

- 500 mL Magnesium Sulfate Solution, 0.5 M (https://www.flinnsci.com/magnesium-sulfate-solution-0.5-m-500-ml/m0167/) OR Unscented Epsom salt (a small 3 lb bag will be plenty) and 500 mL distilled water

- 500 mL Sodium Carbonate Solution, 0.1 M (https://www.flinnsci.com/sodium-carbonate-solution-0.1-m-500-ml/s0235/)

- Sodium Dihydrogen Citrate, 25 g (https://www.flinnsci.com/sodium-dihydrogen-citrate-25-g/s0455/)

- pack of white chalk, 12 each (such as Crayola 51-0320)

- pack of assorted food color & egg dye, 1 fl oz. (such as McCormick brand)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/rice2-crystalline-cloth-model-water-treatment-filters] to print or download.Pre-Req Knowledge

Be familiar with lab safety; understand how to use a digital mass balance; understand percent calculations.

Introduction/Motivation

[Set up the Crystalline Cloth PowerPoint Presentation to show students. Distribute Post It Notes for students to use in Slide 9.]

[Show slides 1-6, which corresponds to the following paragraph and cover the distribution of Earth’s water and why it’s important to have clean water.]

How do we clean water? As a civilization we use many different methods to ensure we have enough clean water to live. However, many of the methods that work for some situations don’t work for others.

For example, one traditional water treatment process is flocculation, or the process of forcing suspended solids and impurities in the water to clump up so that they are more easily removed. Unfortunately, in some situations, this isn’t exactly feasible, so scientists have had to come up with different methods. One of the more technologically intensive, but efficient, methods is via membrane distillation.

[Show slides 7-10 to help introduce membrane distillation.]

Membrane distillation is a separation process that uses a hydrophobic membrane to separate aqueous solutions by using different temperatures. Unlike traditional distillation, it does not require the heating of the bulk of the feed liquid, only the liquid directly in contact with the membrane, saving vast amounts of energy.

The fact that the membrane is hydrophobic prevents the liquid water from moving through the membrane. However, if the liquid is heated enough to force a phase change to vapor, then the vapor will be able to pass through the membrane. Sometimes, the dissolved ions and salts in the water will stick to the membrane, causing scaling to build up which prevents the membrane from functioning as efficiently, and eventually prevents the distillation process entirely.

[Show slides 11-18 to get students brainstorming about cleaning membranes, on slide 14, download and show the Crystalline Cloth Video File (about 169 MB) about membrane distillation, and introduce the lab procedure.]

There are many ways to deal with the scaling of a membrane, and one effective way would be to take the system down in order to chemically or physically clean the membrane, removing the mineral crystals and scale. However, some applications for water treatment need an uninterrupted flow, so what do you do if you can’t afford to be without water while you clean the system?

An easy answer is just to have two systems, and swap whenever you need to clean. Having two systems may be effective, but this can still cause problems. What if there was something we could do to delay the need for cleaning, or prevent it altogether? Today, we’re going to be environmental engineers, and see what we can do to a membrane to make it more effective in distillation. Let us begin, shall we?

Procedure

Background

How does a membrane work? It has to allow the desirable material through but prevent the undesirable material. In our case, we’ll be using cloth to simulate the membrane, and we are creating a supersaturated solution of salt to show how dissolved solids can precipitate out, causing scaling. Sometimes, the shape of the crystals that make up the scaling can play a part in how difficult it is to clean off or prevent from growing in the first place. (If time, sugar can be used to make the scaling in addition to salt, since sugar crystals are rough looking and shaped like rectangles with pointed ends while salt crystals are cube shaped (like dice) and have six sides.)

In this experiment, the students will choose chemicals to treat the membrane itself in an effort to curb crystal growth. some are solid or gel coatings that the students will be able to spread onto the cloth, while others are chemical solutions the students should dip their cloth into, then allow to dry before putting cloth into their crystal solutions.

These are the chemicals/treatments and how they should be applied:

| Chemical/treatment | Reason to use | How to apply |

| Candle | is hydrophobic and it changes the cloth surface | rubbed onto cheesecloth |

| Petroleum jelly | is hydrophobic and it changes the cloth surface | rubbed into cheesecloth |

| Chalk | increases surface area for crystal formation | rubbed into cheesecloth |

| Food Coloring | allows for the ability to see crystal formation better, aesthetically pleasing | in the crystal growth solution |

| Calcium Chloride Solution | cheap and easily accessible chemical for crystal growth |

cheesecloth dipped in solution |

|

Magnesium Sulfate - aka Epsom salts |

cheap and easily accessible chemical for crystal growth | cheesecloth dipped in solution |

| Sodium Carbonate | cheap and easily accessible chemical for crystal growth | cheesecloth dipped in solution |

Note: The bulk of this activity is separated into two portions: Day 1: Pre-lab and Day 2: Lab, designed to be done on different days, about a week apart. During the Pre-lab, the students will be growing crystals on their cloth to simulate scaling, observe, and record the amount of crystals that grew. During the Lab portion, the students will be effectively repeating their experiment, but first testing a treatment to the cloth in an effort to prevent crystal growth. On an additional Day 3: Post-lab portion, students compare the effectiveness of their treatments and discuss the importance of water filtration.

Day 1: Pre-lab

Before the Activity

- Gather materials, and print out copies of the Crystalline Cloth Student Sheet and Crystal Solution Instruction Sheet (alternatively, display the Instruction Sheet via a projector or screen)

With the Students

- Divide class into teams of two students each. Hand out materials (not including the treatment materials) and worksheets.

- Direct groups to retrieve safety equipment (gloves, glasses, potholders, aprons) as needed and put equipment on.

- Direct students to create a saturated solution with approximately 250 mL of distilled water in a 400 mL beaker. Have students carefully place the beaker onto a hot plate. Bring the solution to a slow boil and add a small spoonful of salt (or sugar). When it dissolves, add more; continue to add until no more will dissolve. (This should take about 250 g, or roughly same volume of water.)

- While one student in the group is creating a solution, direct another to attach their cloth swatch to the skewer, and check that cloth can fit inside the beaker or jar used for crystal growth. If needed, use paper clips as weights to keep cloth hanging down.

- Direct students to detach cloth from the skewer, and record the mass (including any weights, if used) under [Cloth Mass] on their student sheet. After recording, students should then reattach cloth to the skewer.

- Have students (or teachers) carefully remove saturated solutions from the hot plate using all safety equipment. (If students are taking the experiment home, have them pour it into a mason jars now.)

- Direct students to suspend cloth in the beaker so that it hangs flat and is securely held by the skewer.

- Have students label and set experiments in an undisturbed location. Optional: wrap the beaker with a towel to help the solution cool slowly and cover with aluminum foil to prevent dust. (Towel is no longer needed after a few hours/the next day.)

- Experiments should sit for at least a few days to allow crystal growth. (We found the best timing to be about a week. The important thing is to not disturb it and keep in a place with little to no temperature fluctuations.)

- After experiment time is completed, direct students to remove cloth and crystals from the beaker and let drip dry. (Student may carefully suspend cloths in a dry beaker or between two books and leave overnight to ensure they are completely dry.)

- Students should now observe and sketch/describe their crystals. Optional: Use microscopes to help get a better view of the crystals and make more accurate sketches.

- Students then need to determine the mass of crystals and cloth and record under [Crystal and Cloth Mass] on their student sheet.

- Direct students to subtract [Cloth Mass] from [Crystal and Cloth Mass] and record under [Crystal Mass (GC1)].

- Have students to complete the questions under the Pre-lab section and get your initials.

Day 2: Lab

Before the Activity

- Gather materials and place treatment options in a central area in the room.

- If using Epsom salt, mix approximately 30 g into 500 mL of water to form a 0.5 M solution.

- Introduce treatment options, be sure to demonstrate/explain how to apply each one prior to beginning the experiment.

With the Students

- Divide class back into their teams of two. Hand out materials.

- Direct groups to retrieve safety equipment (gloves, glasses, potholders, aprons) as needed and put equipment on.

- Instruct students to choose one of the treatment options and apply to their cloth. If they are using the Calcium Chloride, Magnesium Sulfate, or Sodium Carbonate solutions, ensure they know that they will need to let the cloth dry before they are able to put it into the crystal solution.

- Direct students to create a saturated solution with approximately 250 ml of distilled water in a 400 mL beaker. Have students switch roles from Day 1 (i.e., the student who attached the cloth to the skewer on Day 1 now makes the saturated solution.)

- Have students carefully place the beaker onto a hot plate. Bring it to a slow boil and add a small spoonful of your salt (or sugar). When it dissolves, add more; continue to add until no more will dissolve. (This should take about 250g, or roughly same volume of water.)

- While one student in the group is creating a solution, direct another to attach their treated cloth swatch to the skewer and check that cloth can fit inside the beaker or jar used for crystal growth. If needed, use paper clips as weights to keep cloth hanging down.

- Direct students to detach cloth from the skewer and record the mass (including treatment and any weights, if used) under [Treated Cloth Mass] on their student sheet. After recording, students should then reattach cloth to the skewer.

- Have students (or teachers) carefully remove saturated solutions from the hot plate using all safety equipment. (If students are taking the experiment home, have them pour it into a mason jars now.)

- Direct students to suspend cloth in the beaker so that it hangs flat and is securely held by the skewer.

- Direct students to set experiments in an undisturbed location. Optional: Wrap the beaker with a towel to help the solution cool slowly and cover with aluminum foil to prevent dust. (Towel is no longer needed after a few hours/the next day.)

- Experiments should sit for at least a few days to allow crystal growth. (We found the best timing to be about a week. The important thing is to not disturb it and keep in a place with little to no temperature fluctuations.)

- After experiment time is completed, direct students to remove cloth and crystals from the jar and let drip dry. (Student may carefully suspend cloths in a dry beaker or between two books and leave overnight to ensure they are completely dry.)

Day 3: Post-lab

With the Students

- Students should now observe and sketch/describe their crystals. Optional: Use microscopes to help get a better view of the crystals and make more accurate sketches.

- Students then need to determine the mass of crystals and cloth and record under [Crystal and Treated Cloth Mass] on their student sheet.

- Direct students to subtract [Treated Cloth Mass] from [Crystal and Treated Cloth Mass] and record under [Crystal Mass (GC2)].

- Instruct students to calculate the Grown Crystals Reduction (%GCR) value using their data from the Pre-lab and Lab portions.

- Have students discuss why they thought their treatment was effective, then go find at least two other groups to compare percent reductions and treatments.

- Ask students the Investigating/Essential Questions to reconnect their activity back to environmental engineering and the importance of filtration and clean water.

Vocabulary/Definitions

aqueous: A solution in which the solvent is water.

crystallization: The process by which a solid forms and the atoms are highly organized into a structure known as a crystal. Attributes of the crystal depend on factors such as temperature and air pressure.

distillation: The process of separating components from a liquid mixture by selective boiling and condensation.

fouling: The accumulation of unwanted material on solid surfaces to the detriment of function.

hydrophobic: The physical property of a molecule that is seemingly repelled from a mass of water.

membrane: A selective barrier that allows some things to pass through but not others.

scaling: Also known as precipitation fouling. It involves crystallization of solid salts, oxides, and hydroxides from solutions.

Assessment

Pre-Activity Assessment

Brainstorming: Have students discuss possible challenges to water filtration, and what steps, if possible, could be taken to mitigate the issue. As a class, record ideas on the board.

Activity Embedded (Formative) Assessment

Brainstorm: After observing and sketching their crystals, lead students in discussion of what effect these crystals would have on the cloth being used as a filter (crystals reduce the effectiveness of the filter and cause it to need to be cleaned or replaced).

Discussion: Lead students to consider how to maintain the cloth as a viable water filter. During the discussion, direct students to consider the time and resource cost of shutting down a filtration or distillation apparatus for maintenance. Scientists and engineers are researching methods to prevent the fouling of the filtration medium, making scale removal unnecessary. Students will develop a plan to inhibit or prevent crystal growth. Direct the students to consider possible treatments to prevent crystal growth on their cloth swatches. Record solutions on the board.

Post-Activity (Summative) Assessment

Evaluation:

- Ask students to compare their results to other groups.

- Initial students’ submissions after they explain/defend their reasoning for given solutions.

Once student groups have completed the activity, students compare their Grown Crystal Reduction percentages (%GCR) in order to determine the most effective treatment and solution for the crystal fouling problem in membrane distillation.

Investigating Questions

- Why is water filtration important? (Answer: Unfiltered water can be a source of deadly diseases and other harmful contaminants.)

- Where could it be vital for life? (Answer: In many underdeveloped countries, desert locations, places affected by natural disasters that knock out municipal water access.)

- What types of scaling/fouling can occur? (Answer: Types of fouling can include: biological, chemical, precipitation, particulate, corrosion fouling.)

- What are different types of ways scaling/fouling can be controlled? (Answer: either removal of the scaling/fouling after it has been deposited, through either physical or chemical action. Or, by prevention of the fouling in the first place.)

- What are the costs/benefits associated with each way scaling/fouling can be controlled? (Answer: chemical removal: expensive, and chemicals used could leave residual traces in the water supply. physical removal: must shut down the system leaving residents with no clean water in the meantime. Pre-emptive prevention: can be very costly, increasing the cost of the filtration system itself.)

Safety Issues

- Students need to be wearing gloves, eye protection and aprons while working with hot plates and solutions. In addition, they will need potholders to move their beakers off the hot plates.

Troubleshooting Tips

Control crystallization factors: Store crystal solution in an area that is clean, will not be disturbed and will maintain a constant temperature. In addition, use distilled water--not tap! Tap water may contain contaminants that will hinder crystal growth.

If you do not have that much time you can have the children make the original and make their engineered descaling solution and then take it home. Students can then upload pictures and a description of their engineered solution into a Google Drive folder. Student pictures can be loaded into class folders and analyze how their design is compared to other students’ designs.

Activity Extensions

- Have the students grow crystals for a longer period of time and discuss how incubation time affects crystal growth.

- Change the size of the cheesecloth and/or material used for crystal nucleation to illustrate how surface area affects crystal growth.

- If time permits, students could develop a culminating treatment, utilizing a combination of the most effective treatments.

- Have students research the cost of their treatment and use it to do a cost/benefits analysis of using their treatment to prevent crystal growth.

Activity Scaling

- Have upper-level students research actual membrane distillation systems and hypothesize ways they could improve on current designs. Furthermore, have them brainstorm how socio-economically disadvantaged areas can clean their water on a limited budget.

- Special Education students should explain how atoms and molecules arrange to form crystals. Allow them to make sugar crystals to eat (with parental approval). Have them identify other objects that are crystals (such as amethyst, diamonds, quartz, etc.) and where they occur on Earth.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are presented with examples of the types of problems that environmental engineers solve, specifically focusing on water quality issues. Topics include the importance of clean water, the scarcity of fresh water, tap water contamination sources, and ways environmental engineers treat contamin...

Copyright

© 2021 by Regents of the University of Colorado; original © 2020 Rice UniversityContributors

Courtney Kehler; Christina Crawford; Annie Pham; Carl BoydSupporting Program

Research Experience for Teachers (RET) under Rice University Engineering Research Center for Nanotechnology Enabled Water Treatment Systems (NEWT)Acknowledgements

Carolyn Nichol, Christina Crawford, Dr. Li’s Lab, National Science Foundation. This curriculum was based upon work supported by the National Science Foundation under Rice University Engineering Research Center for Nanotechnology Enabled Water Treatment Systems (NEWT) RET grant no.1449500. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: March 14, 2023

User Comments & Tips