Quick Look

Grade Level: 7 (6-8)

Time Required: 2 hours

(2-8 class periods)

Expendable Cost/Group: US $2.00 This activity also requires some non-expendable items; see the Materials List for details.

Group Size: 2

Activity Dependency: None

Subject Areas: Science and Technology

NGSS Performance Expectations:

| MS-ETS1-1 |

Summary

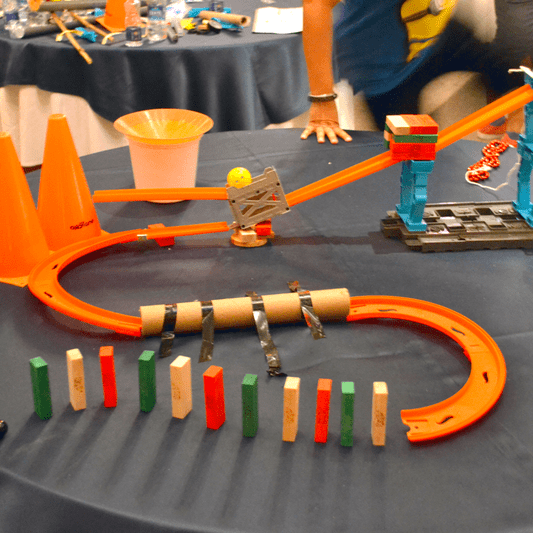

Engineer and cartoonist Rube Goldberg is famous for his crazy machines that accomplish everyday tasks in overly complicated ways. Students use their new understanding of types of simple machines to design and build their own Rube Goldberg machines that perform simple tasks in no less than 10 steps.Engineering Connection

Engineers continually dip into their wells of creativity to come up with new and innovative ways of completing tasks. The classic and fundamental simple machines are incorporated and combined into an endless number of items designed by engineers and used everyday. This activity challenges students to bring out their creative side in designing complex machines to perform simple tasks.

Learning Objectives

After this activity, students should be able to:

- Create practical representations of simple machines (prototypes).

- Follow the steps of the engineering design process.

- Use tools safely.

- Learn the five elements of a technology system: goal, inputs, processes, outputs and feedback.

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Brainstorming is a group problem-solving design process in which each person in the group presents his or her ideas in an open forum.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Specify criteria and constraints for the design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Make two-dimensional and three-dimensional representations of the designed solution.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Differentiate between inputs, processes, outputs, and feedback in technological systems.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Develop innovative products and systems that solve problems and extend capabilities based on individual or collective needs and wants.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Create solutions to problems by identifying and applying human factors in design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Analyze how an invention or innovation was influenced by its historical context.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Identify and explain appropriate measuring tools, hand tools, and power tools used to hold, lift, carry, fasten, and separate, and explain their safe and proper use.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify and explain the safe and proper use of measuring tools, hand tools, and machines (e.g., band saw, drill press, sander, hammer, screwdriver, pliers, tape measure, screws, nails, and other mechanical fasteners) needed to construct a prototype of an engineering design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Demonstrate methods of representing solutions to a design problem, e.g., sketches, orthographic projections, multiview drawings.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Describe and explain the purpose of a given prototype.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify appropriate materials, tools, and machines needed to construct a prototype of a given engineering design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain how such design features as size, shape, weight, function, and cost limitations would affect the construction of a given prototype.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify the five elements of a universal systems model: goal, inputs, processes, outputs, and feedback.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

- examples of simple and complex machines (pulleys, hammer, ramps, bicycle, wheelbarrow, etc.)

- illustrations of Rube Goldberg machines

Example of a Rube Goldberg machine. See more cartoons at www.rubegoldberg.com. - assorted wood, metals, plastics and composites

- foam core board and extruded foam insulation make good bases as they are light, sturdy, and easy to attach things to

- miscellaneous construction materials such as wire hangers, cardboard, screws, wire, string, glue and tape

- assorted tools, such as screwdrivers, saws, drills and hammers

- poster paper, markers, crayons, pencils, rulers, etc.

- assorted discarded "raw materials," for student prototypes

- assorted materials that students bring from home, which may be returned at project end

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/rube_goldberg_machine] to print or download.Pre-Req Knowledge

A familiarity with the six types of simple machines: inclined plane, wedge, screw, lever, wheel and axle, and pulley.

Ability to safely use tools, such as screwdrivers, saws, drills and hammers.

Introduction/Motivation

(Show students a few Rube Goldberg cartoons that feature his crazy inventions.) For 55 years, Rube Goldberg's award winning cartoons satirized machines and gadgets that he saw as excessive. His cartoons combined simple machines and common household items to create complex, wacky and diabolically logical machines that accomplished mundane and trivial tasks.

His inventions became so widely known that Webster's Dictionary added "Rube Goldberg" to its listing, defining it as "a comically involved, complicated invention, laboriously contrived to perform a simple operation." His "inventions," drawn for our pleasure, can actually work. By inventing excessively complex ways to accomplish simple tasks, he entertained us and poked fun at the gadgets designed to make our lives easier. In his words, the machines were a "symbol of humans' capacity for exerting maximum effort to achieve minimal results."

He believed that most people preferred doing things the hard way instead of using simpler, more direct paths to accomplish goals. The resulting inventions are collections of bits and pieces, parts of now useless machines, scraped together to achieve an innovative, imaginative, yet somehow logical contraption to conquer the job at hand.

The following are examples of tasks that can be illustrated using the Rube Goldberg technique: putting toothpaste on a toothbrush; adhering a stamp to a letter; selecting, cleaning, and peeling an apple; turning on a radio; toasting a slice of bread. Can you think of your own?

Procedure

Background

As necessary, review with students the basics of simple machines: inclined plane, wedge, screw, lever, wheel and axle and pulley.

As necessary, provide students with the training to use any tools they need, such as screwdrivers, saws, hot glue guns, drills and hammers.

Preparation

- Gather materials, including those provided by students.

- Make copies of the Student Activity Worksheet.

- Choose a time frame for completion of machines.

With the Students

As a class:

- Review the types and combinations of simple machines in use around us every day.

- Brainstorm how simple machines might be incorporated into more complex machines.

- Brainstorm simple tasks that lend themselves to the project.

- Look at illustrations of Rube Goldberg machines.

- Discuss any safety concerns that students must be aware of pertaining to the supplies and tools available to them.

- Explain requirements and expectations for the assessment (grading) rubric. Provide design constraints and criteria. Perhaps minimum number of steps and/or minimum number of types of simple machines incorporated. Given classroom space constraints, it may be helpful to set a maximum overall volume of the finished machine prototype.

- Divide the class into groups of students.

- Have each team identify a basic task and design a machine to accomplish that task in no less then 10 steps.

- Have each team produce a schematic design, labeling each part and its function, indicating materials, and describing each step needed to accomplish the task. Teams should discuss how

Vocabulary/Definitions

prototype: A first attempt or early model of a new product or creation. May be revised many times.

schematic: Showing the basic form or layout of something.

Assessment

Investigating Questions

- How can we build a device that incorporates all the six types of simple machines and accomplishes a basic task in no less then 10 steps?

- How can we represent the process used to complete this design from goal to feedback?

- Does the prototype accomplish the basic task in no less then 10 steps?

- How does the prototype work to accomplish this task in no less then 10 steps?

- Does or could this prototype have a practical application?

- What changes would we make to the prototype based on our testing experiences – both successes and failures - during the design process? How would you make it better, funnier, more reliable, safer? (Engineers ask these questions when they design and improve products and machines.)

- How do we use tools to shape, cut, and/or fabricate elements of the design?

Additional Multimedia Support

Learn more about Rube Goldberg and see examples of his cartoon illustrations at the official Rube Goldberg website: http://www.rubegoldberg.com/.

Refer to the information, lessons and activities of the seventh-grade Simple Machines unit in the TeachEngineering collection.

Learn more about the steps of the engineering design process at: https://www.teachengineering.org/populartopics/designprocess

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Through the cartoons of Rube Goldberg, students are engaged in critical thinking about the way his inventions make simple tasks even harder to complete. As the final lesson in the simple machines unit, the study of Rube Goldberg machines can help students evaluate the importance and usefulness of th...

Students expand upon their understanding of simple machines with an introduction to compound machines. This lesson encourages students to critically think about machine inventions and their role in our lives.

Students research and learn about simple machines and other mechanisms through learning about a Rube Goldberg machine. Student teams design and build their own Rube Goldberg devices that incorporate at least six simple machines. This project is open-ended with much potential for creativity and fun.

References

Rube Goldberg is the ® and © of Rube Goldberg, Inc. Students can enter designs in the annual Rube Goldberg Machine Contest. For current information, contact Rube Goldberg Inc. at www.rubegoldberg.com or 212-371-3760.

Copyright

© 2013 by Regents of the University of Colorado; original © 2005 Worcester Polytechnic InstituteSupporting Program

Center for Engineering Educational Outreach, Tufts UniversityLast modified: April 7, 2022

User Comments & Tips