Quick Look

Grade Level: 11 (10-12)

Time Required: 1 hour

Expendable Cost/Group: US $2.50

Group Size: 4

Activity Dependency: None

Subject Areas: Data Analysis and Probability, Problem Solving, Science and Technology

Summary

Learn the basics of LEAN manufacturing! In this activity, students participate in a simple manufacturing process to identify and eliminate waste via collaboration and analyzing data to optimize the process. Students learn how to do small scale, rapid testing of change ideas and measurement to improve a process. The purpose of this activity is relatively simple: assemble a sticker face (in the style of Potato Head) as quickly as possible with all the right pieces in place and in the right position.Engineering Connection

Industrial and systems engineers solve complex problems in the manufacturing process. They use processes like LEAN to ensure that a system is efficient and produces high-quality products. An industrial and systems engineer studies and looks to improve upon work measurement, methods and operations, ergonomics, and inventory. Engineers tackle work measurement usually via a time study to determine the capacity of a facility in terms of realistic works orders, delivery dates, and costs. Not only does a facility use this knowledge to determine its initial manpower, but also to propose alternative methods for production.

Learning Objectives

After this activity, students should be able to:

- Explain LEAN methodology as applied to industrial and systems engineering.

- Create a simple LEAN manufacturing process by identifying and eliminating waste.

- Recognize the value of a collaborative process.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

-

Analyze data using tools, technologies, and/or models (e.g., computational, mathematical) in order to make valid and reliable scientific claims or determine an optimal design solution.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

-

When investigating or describing a system, the boundaries and initial conditions of the system need to be defined.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

Common Core State Standards - Math

-

Summarize, represent, and interpret data on a single count or measurement variable

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Use computers and calculators to access, retrieve, organize, process, maintain, interpret, and evaluate data and information in order to communicate.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Conduct research to inform intentional inventions and innovations that address specific needs and wants.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Use various approaches to communicate processes and procedures for using, maintaining, and assessing technological products and systems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- 12 extra-large plastic Easter eggs (this activity is written using 4 eggs of each color; purple, yellow, pink, blue; the activity will work with minor changes if other colors/amounts are used). Available online: https://www.amazon.com/Jumbo-Piece-Assorted-Colors-Easter/dp/B06XKGWV8Y

- Face stickers (eyes, nose, mouth, ears, glasses, mustaches). Available online: https://www.amazon.com/JOYIN-Sticker-Safaris-Fantasy-Supplies/dp/B07R4PMWHF/ref=sr_1_5?dchild=1&keywords=face+stickers&qid=1585070879&sr=8-5

- Time-keeping device (such as a stopwatch)

- 3 Quality Control Checklists (cut up)

- 3 Product Sheet (cut up)

- 3 Product Images (cut up)

- 4 large shallow bins or cookie sheets (for cut up stickers in System 1)

- 8-12 shallow bins (for cut up stickers in System 2)

- (optional) plastic bags to organize cut up stickers and/or checklists, images, etc. for each system.

Each person needs:

- Scrap paper

- Writing utensil

- Lab Worksheet

- Student Version Worksheet (optional, but helpful)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uconn-2523-lean-manufacturing-process-activity] to print or download.Pre-Req Knowledge

Students should have basic knowledge of manufacturing (for example, the types of people involved and their roles; what manufacturing does to create a product; and how it can be improved by evaluating current process).

Introduction/Motivation

Today we are going to become industrial and systems engineers! We will be overseeing and modifying an engineering process and our goal is to optimize the system to produce desired behaviors and results.

What is industrial and systems engineering? Industrial and systems engineering is an interdisciplinary field of engineering and management that aims to solve complex problems that oversee a manufacturing process. The job goes beyond the assembly line, delving into the parts suppliers, the distribution of a product, the employees, the processes, the machines, and even the way a facility is designed.

An industrial and systems engineer studies and looks to improve upon work measurement, methods and operations, ergonomics, and inventory. Engineers tackle work measurement as a time study to determine the capacity of a facility in terms of realistic works orders, delivery dates, and costs. Not only does a facility use this knowledge to determine its initial workforce, but also to propose alternative methods or to identify the possibility of underperforming employees. They consider things like repetitive versus non-repetitive tasks and what that means for an employee in terms of productivity and mandatory breaks. Industrial systems engineers also take a broader look and perform an operational analysis looking for possible work simplification and ways to make continuous improvements. This analysis looks at tooling and machinery, individual process layouts, the overall plant layout, and the workplace environments in general through ergonomics. Some consider ergonomics the bridge between the engineer and the end-user of the product as it encompasses both the safety and comfort of the employee as well as the consumer.

The activity we are going to do today is primarily concerned with something called LEAN manufacturing. LEAN Manufacturing was derived from the Toyota Management System and focuses on a process or a set of processes with a goal of reducing waste and increasing speed and efficiency. LEAN is a management process in which manufacturing efficiency and product quality are equally important. A LEAN facility checks to ensure that each step of a process adds value to efficiency and/or quality. In a LEAN facility, all employees have a voice, and each person is valued for their contributions, large or small.

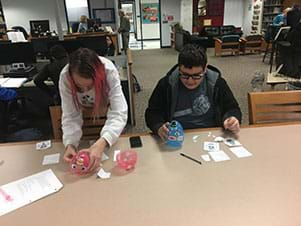

Today we are going to learn how to do small scale, rapid testing of change ideas and measurement to improve a process. The purpose of this activity is relatively simple: assemble a sticker face (in the style of Potato Head) as quickly as possible with all of the right pieces in place and in the right position. Each team member will have one of the following jobs:

- The “line supervisor” assigns jobs to the personnel on the team, answers questions, and times the process from start to finish. The line supervisor is also responsible for documenting the number of products completed during the cycle, recording the errors made as reported by the quality control inspector, and communicating with team members and listening to their thoughts on ways to eliminate waste and to improve quality and efficiency. If the line supervisor determines someone is not doing their job, they may re-assign positions and may even be put in the difficult scenario of eliminating a position.

- The “supplies handler” is responsible for going to the warehouse and gathering the necessary supplies. It is up to the line supervisor and the supplies handler to determine if they wish to retrieve all the supplies at once or product by product.

- The “assemblers” build the product. In this case, they are the workers in an assembly line that place the stickers on the eggs. It is up to the line supervisor if each assembler builds a product from start to finish or if one person is responsible for just the eyes, another the nose and mouth, and perhaps a third for the accessories.

- The “quality control inspector” determines if errors have been made in selection of materials or their placement on the egg. The quality control inspector determines the number of defects and the number of opportunities in a product.

Now the goal is to make your Potato Head-like egg as quickly as possible but with all the right pieces in place and in the right position. Your team will need to weigh speed against accuracy.

Procedure

Background

In the following activity, students model LEAN manufacturing. A LEAN facility checks to ensure that each step of a process adds value to efficiency and/or quality. In a LEAN facility, all employees have a voice, and each person is valued for their contributions, large or small. Students explore the importance of reflecting on the manufacturing process to improve it as they move through three Systems. System 1 is the most disorganized; the warehouse with parts is outside of the classroom, the parts (stickers) are all cut apart, and the supplied handler is working off a list to select the correct stickers. After timing their work and calculating a ratio of defects (for example, wrong sticker placement) to opportunities (for example, a product with one egg and seven stickers has 15 opportunities), students list ways to improve the assembly process. The processes in System 2 is simpler than System 1, and is intended to incorporate common improvements students think of. System 3 again improves over System 2. By brainstorming improvements, students replicate how each person’s voice is valued in LEAN manufacturing, and how a LEAN facility continuously seeks to improve efficiency.

Before the Activity

- For System 1: Set up the first system in a nonsensical manner so that students draw the conclusion that the workers/people are not the root problem but rather the organizational system is the problem.

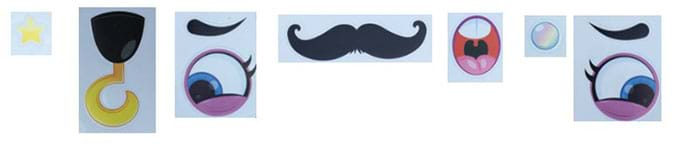

- Cut up all the stickers individually. (For example, if pairs of eyes come together as one sticker, cut them apart so the materials handler must search for the matching eyes.) See Figure 1.

- Put all the cut-up stickers into a shallow bin. Make sure there are many more stickers than are necessary.

- Make copies and cut up the Quality Control Checklists and the Product Sheets for each group.

- Cut up Product Images for each group.

- Match cut up quality control checklists and product lists for each group (so products on each sheet match)

- Make copies of lab worksheets, one for each student.

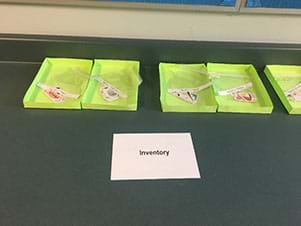

- Create a “warehouse” area outside of the classroom (if possible) or within the classroom (in an inconvenient location.) Place the sticker bins in the “warehouse” area.

- Create a final product location (the Inventory) outside of the classroom (if possible) or within the classroom (in an inconvenient location.)

- For System 2: Hopefully this system incorporates some, if not all, of the ideas students suggested for improvement.

- Cut up all the stickers but keep things more organized. (For example, if pairs of eyes come together as one sticker, keep them together.)

- Put all the cut-up stickers into shallow bins, sorting by eyes all in one bin, ears all in one bin, mouths all in one bine, etc. Make sure there are more extra stickers in each bin.

- Make copies and cut up the Quality Control Checklists and the Product Sheets for each group.

- Cut up the Product Images for each group. See Figure 2.

- Match cut up quality control checklists, product lists, and images for each group (so products on each sheet match).

- Move the “warehouse” area inside the classroom. Place the sticker bins in the “warehouse” area.

- Create a final product location inside the classroom.

- For System 3: Hopefully this system incorporates the rest of the ideas students suggested for improvement.

- Put only the necessary stickers into the sticker bins so there is no sorting (do not cut up the sticker sheet). See Figure 3.

- Make copies and cut up the Quality Control Checklists and the Product Sheets for each group.

- Cut up Product Images for each group.

- Match cut up quality control checklists, product lists, and images for each group (so products on each sheet match).

- Keep the “warehouse” area inside the classroom. Place the sticker bins in the “warehouse” area.

- Keep the final product location inside the classroom.

NOTE: All left/right designations are from the assembler’s point of view. Do NOT use the large face/body sticker. Instead, use a plastic egg of the designated color for each product.

With the Students

- Divide students into groups and distribute the Lab Worksheet and Student Version worksheet.

- Note: the Student Version Worksheet is an optional, but helpful overview of LEAN manufacturing principles and concepts, and includes some math work to help students connect data analysis to engineering. The worksheet also contains space to answer questions from the Pre-Activity Assessment (see below).

- Determine the number of necessary jobs: line supervisor, supplies handler, assemblers (as many as needed), and quality control inspector. (Positions can be added or subtracted as needed.)

- Give students three minutes to assign each team member to a job listed below:

- The “line supervisor” assigns jobs to the personnel on the team, answers questions, and times the process from start to finish. The line supervisor is also responsible for documenting the number of products completed during the cycle and recording errors made as reported by the quality control inspector. The line supervisor is responsible for communicating with team members and listening to their thoughts on ways to eliminate waste and to improve quality and efficiency. If the line supervisor determines someone is not doing their job, they may re-assign positions and even may be given the difficult scenario of eliminating a position.

- The “supplies handler” is responsible for going to the “warehouse” and gathering the necessary supplies. It is up to the line supervisor and the supplies handler to determine if they wish to retrieve all the supplies at once or product by product.

- The “assemblers” build the product. In this case, they are the workers in an assembly line that place the stickers on the eggs. It is up to the line supervisor if each assembler builds a product from start to finish or if one person is responsible for just the eyes, another the nose and mouth, and perhaps a third for the accessories.

- The “quality control inspector” determines if errors have been made in selection of materials or their placement on the egg. The quality control inspector determines the number of defects and the number of opportunities in a product.

- Give students three minutes to determine the process for their first system by answering these questions:

- The line supervisor and supplies handler need to determine if they wish to retrieve all the supplies at once or product by product.

- The line supervisor needs to decide if each assembler builds a product from start to finish or if one person is responsible for just the eyes, another the nose and mouth, and perhaps a third for the accessories.

- Provide students with the following constraints:

- The line supervisor cannot touch any materials except the final product.

- Only the supplies handler can obtain materials for the assemblers.

- All products must be accompanied by the order ticket (cut outs from the product list).

- NOTE: All left/right designations are from the assembler’s point of view. Do NOT use the large face/body sticker. Instead, use a plastic egg of the designated color for each product.

- Have students perform System 1 and record the process and calculations on their lab worksheets. Rules for System 1:

- Record the time it takes assemble your line’s four products.

- The line supervisor cannot touch any materials except the final product.

- Only the line supervisor can move the product to inventory.

- All products must be accompanied by the Quality Control Checklist.

- Students will need to calculate the number of opportunities. The egg and each sticker procured is an opportunity and the placement of each sticker is another opportunity. Example: Seven stickers and one egg procured, and seven stickers placed results in 15 opportunities.

- The quality control inspector will need to determine the number of defects. Examples of defects: If the wrong color egg is used for a product that is a defect. Any incorrect sticker is considered a defect. Any incorrect sticker placement is considered a defect. In short, anything that is not what the customer is expecting is considered a defect.

- Students will need to calculate the ratio of number of defects to total opportunities: The DPO ratio describes the average defects in each unit produced or a measure of the probability of defects. Since one unit can have multiple defects, this ratio can be greater than 1! The lower the ratio, the better the system; the higher the ratio, the more likelihood of defects, loss of revenue, and poor customer satisfaction.

- Students will need to determine any wasteful steps or problems with the process. List ways in which the process can be improved.

- Set up for System 2. Hopefully this system incorporates some, if not all, of the ideas students suggested for improvement. In System 2, the materials handler has an image to assist with procuring the necessary supplies. In addition, both the materials and final product locations are inside or near the classroom to save time. The stickers, while still jumbled, are slightly more organized in that sets of eyes are together. There should still be additional stickers. However, to test that the improvements really are the process, and not the people, have the groups switch product lines (i.e., Group 1 now makes the products that Group 2 made in System 1, Group 2 makes Group 3’s products, etc.)!

- Have students perform System 2, recording data on their lab worksheets. Rules for System 2:

- Record the time it takes assemble your line’s four products.

- The line supervisor cannot touch any materials except the final product.

- Only the supplies handler can obtain materials for the assemblers.

- All products must be accompanied by the order ticket (cut outs from the product list).

- The supplies handler has an image to assist with procuring the necessary supplies.

- Switch product lines!

- Set up for System 3. In this version, only the necessary parts are provided so there is no sorting. The supplies and warehouse areas remain inside or near the classroom. Groups should switch product lines again. However, this time, the line supervisor must eliminate at least two workers due to budget cuts! The line supervisor can also re-assign roles at this time in an effort to maintain or further streamline the process. Again, to test that the improvements really are the process, and not the people, have the groups switch product lines!

- Have students perform System 3, once again recording data on their lab worksheets. Rules for System 3:

- Record the time it takes assemble your line’s four products.

- Switch product lines!

- The line supervisor cannot touch any materials except the final product.

- Only the supplies handler can obtain materials for the assemblers.

- All products must be accompanied by the order ticket (cut outs from the product list).

- The materials handler has an image to assist with procuring the necessary supplies.

- The line supervisor must eliminate at least two workers due to budget cuts!

- The line supervisor can also re-assign roles at this time in an effort to maintain or further streamline the process.

Vocabulary/Definitions

LEAN manufacturing: The process to reduce waste in a system without sacrificing productivity.

Assessment

Pre-Activity Assessment

Group Discussion: Have students share jobs they are familiar with (either their own or the job of someone you know well) and discuss the following as a class:

- Name an action that adds value to a process.

- Name an action that does not add any value and may be considered wasteful.

- Name a step in a process that a customer may consider wasteful but is necessary for a business.

Activity Embedded (Formative) Assessment

Lab Worksheet: Have students complete the Lab Worksheet. They record data on their productivity in each of the three systems and reflect on ways that their manufacturing process can be improved.

Post-Activity (Summative) Assessment

Summary: Provide students with the following prompt to connect industrial and systems engineering to other processes in their lives: Summarize a process at your work, or interview a family member, about a process at their work. Write a paragraph about how you think the process could be improved or how they can eliminate waste. Be sure to include an introductory paragraph about the type of company (no names necessary) as well as the process you are critiquing.

Activity Extensions

Use the optional Student Version Worksheet for mini-lesson on LEAN manufacturing concepts, including kaizen and Six Sigma. This mini-lesson allows students to perform some simple data analysis in order to help enrich their understanding of industrial and systems engineering.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!Copyright

© 2021 by Regents of the University of Colorado; original © 2018 University of ConnecticutContributors

Diane Walsh, Joules Fellow, Coginchaug Regional High School, Durham, CT; James Wilson, Laboratory of Intelligent Networks and Knowledge-perception Systems (LINKS), School of Engineering, University of Connecticut; Dr. Shalabh Gupta, Laboratory of Intelligent Networks and Knowledge-perception Systems (LINKS), School of Engineering, University of ConnecticutSupporting Program

Joule Fellows Program, School of Engineering, University of ConnecticutAcknowledgements

This curriculum was developed under National Science Foundation GK-12 grant no. 1711706. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: March 30, 2021

User Comments & Tips