Quick Look

Summary

Materials engineering allows for the design and testing of a variety of different properties so engineers can make decisions on the types of materials to use in a particular structure. In this activity, students create an assigned composite of cement by mixing the concrete with different percentages of black carbon and other material. They then test the physical and chemical properties of their composite to see what properties are improved by the addition of the black carbon. After the class data is collected and all the composites tested are compared to each other, the groups can improve their concrete composite by looking at the group data and re-testing to see if their changes resulted in improvements.Engineering Connection

Engineers must determine what the best material is to use for a given design. Many materials we use are composites of materials, meaning they are made up of more than one type of material (wood, glass, metal, etc.), and the percentages of the materials affect its performance. Material engineering is all about experimenting with and creating new types of materials that we can use to improve functionality of the things around us. In this lab just like the material engineers, students will be able to create composites of their own and go through the engineering process of testing their concrete composites and analyzing their data to see what improvements can be made.

Learning Objectives

After this activity, students should be able to:

- Describe the difference between pure substances and mixtures.

- Discuss what makes a change physical and chemical.

- Test a material for density, wettability, and strength.

- Think and outline a design for improving composite compositions.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-PS1-2. Construct and revise an explanation for the outcome of a simple chemical reaction based on the outermost electron states of atoms, trends in the periodic table, and knowledge of the patterns of chemical properties. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Construct and revise an explanation based on valid and reliable evidence obtained from a variety of sources (including students' own investigations, models, theories, simulations, peer review) and the assumption that theories and laws that describe the natural world operate today as they did in the past and will continue to do so in the future. Alignment agreement: | The periodic table orders elements horizontally by the number of protons in the atom's nucleus and places those with similar chemical properties in columns. The repeating patterns of this table reflect patterns of outer electron states. Alignment agreement: The fact that atoms are conserved, together with knowledge of the chemical properties of the elements involved, can be used to describe and predict chemical reactions.Alignment agreement: | Different patterns may be observed at each of the scales at which a system is studied and can provide evidence for causality in explanations of phenomena. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-PS1-3. Plan and conduct an investigation to gather evidence to compare the structure of substances at the bulk scale to infer the strength of electrical forces between particles. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Plan and conduct an investigation individually and collaboratively to produce data to serve as the basis for evidence, and in the design: decide on types, how much, and accuracy of data needed to produce reliable measurements and consider limitations on the precision of the data (e.g., number of trials, cost, risk, time), and refine the design accordingly. Alignment agreement: | The structure and interactions of matter at the bulk scale are determined by electrical forces within and between atoms. Alignment agreement: | Different patterns may be observed at each of the scales at which a system is studied and can provide evidence for causality in explanations of phenomena. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Use various approaches to communicate processes and procedures for using, maintaining, and assessing technological products and systems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Texas - Science

-

Scientific processes. The student uses critical thinking, scientific reasoning, and problem solving to make informed decisions. The student is expected to:

(Grades

9 -

10)

More Details

Do you agree with this alignment?

-

Science concepts. The student knows that relationships exist between the structure and properties of matter. The student is expected to:

(Grades

9 -

10)

More Details

Do you agree with this alignment?

-

Science concepts. The student knows the characteristics of matter and can analyze the relationships between chemical and physical changes and properties. The student is expected to:

(Grades

10 -

12)

More Details

Do you agree with this alignment?

Materials List

To make concrete composites each group needs:

- 2 silicone molds

- plastic cup

- plastic spoon

For the entire class to share:

- scale

- water

- bag of pure cement

- bag of Quikrete

- composite mix-ins:

- black carbon (required)

- wood shavings, plastic shavings, and/or metal shavings (optional)

To test concrete composites each station needs its own direction slide. You can include more test or exclude tests listed below depending on what materials are readily available in your classroom.

- Physical Property Observations Station: Leading question station handout

- Physical Property Measurement Station: scale, ruler, calculator

- Drop Test Station: dropper, water, soap, rubbing alcohol, phone or camera

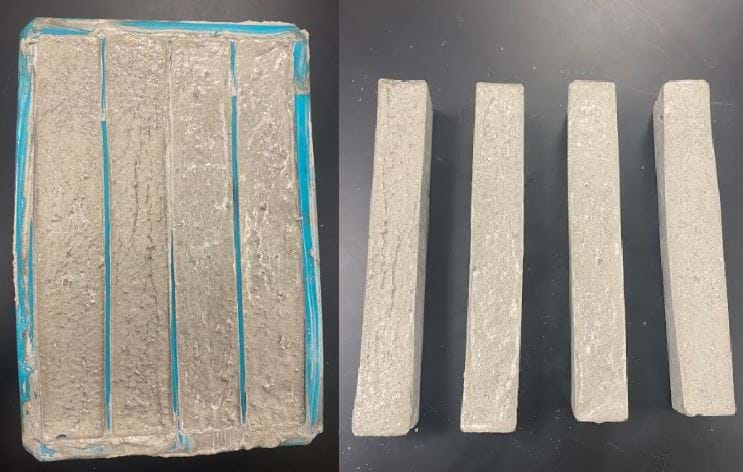

- Solubility Station: cup, spoon, water, scissors (optional)

- Hardness Test Station: Density Cubes Kit (available online: https://www.amazon.com/density-cubes/s?k=density+cubes)

- Strength Test Station: buckets, string, scissors, weights (5 lb increments)

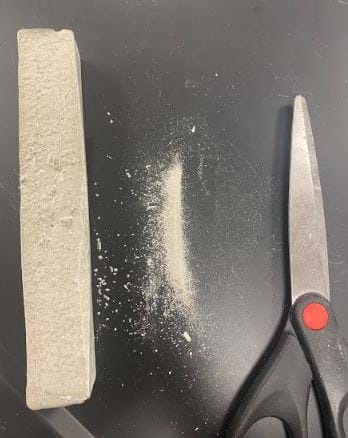

- Acid vs. Base Drop Test Station: hydrochloric acid (HCl), bleach, dropper

For each student:

- eye protection

- chemical-resistant gloves

- laboratory protective equipment (as needed)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uoh-2765-concrete-composites-lab-activity] to print or download.Pre-Req Knowledge

Students should be familiar with vocabulary words such as solid, liquid, gas, element, compound, homogenous mixture, heterogenous mixture, intensive, and extensive. They should also be able to calculate density.

Introduction/Motivation

Why are certain materials better suited to different tasks? Why are pencils made of wood? Why are chairs made of plastic? Why are windows made of glass? Material engineering is at work all around us. Material scientists create new materials and materials engineers improve upon and use on the ones currently available in an ongoing effort to make the material better suited to the job at hand.

To start this activity, choose an item from around the classroom. For that item, I want you to name the different types of materials that compose that item. Notice how all the materials work together to make everyday items function. I want you to think about why these materials are the best suited for the job and what would be the downsides of using a different type of material in its stead. Or explain why you think a different type of material would do a better job.

[Example responses: The body of a pencil is made of wood, the eraser made of rubber, the ferrule made of metal, and the lead made from graphite. If the pencil was made of glass, you wouldn’t be able to sharpen it to get the lead out when it dulls and there is a risk of breaking while using it. Plastic might do a better job because it doesn’t break as easily as glass or wood.]

Now that we understand the types of materials that make certain objects, let’s apply our knowledge to a common type of material often used in engineering: concrete. We will explore how to make a composite, which is a combination of two or more different types of materials which often have very different properties together. Within the finished structure of a composite, the individual elements remain separate and distinct, but their properties are merged creating a material that is unlike the starting materials. Can you make a composite of concrete that stands up to the rigors of testing for engineering design? Let’s get started!

Procedure

Background

A composite is a combination of two or more different types of materials which often have very different properties together. Within the finished structure of a composite, the individual elements remain separate and distinct, but their properties are merged creating a material that is unlike the starting materials. This makes it distinctly different from mixtures and solutions. Concrete on its own and carbon black on its own are going to have distinct properties that are unlike a composite made of concrete and carbon black combined. The hope is that the changes in the properties of the composite will be graphable and easy to see when comparing the different composites that each student group makes.

Before the Activity

- Teacher should assign each group a particular composite to make so that no two groups in the same class period are making the same composite. For example:

Group 1: 100% concrete

Group 2: 95% concrete 5% carbon black

Group 3: 90% concrete 10% carbon black

Group 4: 85% concrete 15% carbon black

Group 5: 80% concrete 20% carbon black

- Gather materials for the lab stations.

- Make copies of the Lab Station Directions and the Concrete Composites Lab Worksheet.

- Set up the Concrete Lab stations so students can test different physical and chemical properties of their cement samples at each station. Feel free to exclude some stations if the materials are not readily available in your classroom.

With the Students

Part 1: Making Concrete Composites

- Each group is assigned a cement or Quikrete Composite to make. Have students check the list to see which composition their group is assigned.

- Using the Scale, measure out the correct number of grams of concrete or Quikrete and carbon black for the composite assigned to your group.

Example: 100% concrete = 100g concrete + 0g carbon black

95% concrete = 95g concrete + 5g carbon black

90% concrete = 90g concrete + 10g carbon black

- To your powder mixture, add 100 mL of water if assigned pure cement or 50mL of water if assigned Quikrete and Mix.

- Divide your mixture into two and pour into the silicone molds. This should give your group 2 concrete samples to test. Make sure to flatten the top of your sample as best as possible to make testing the sample easier.

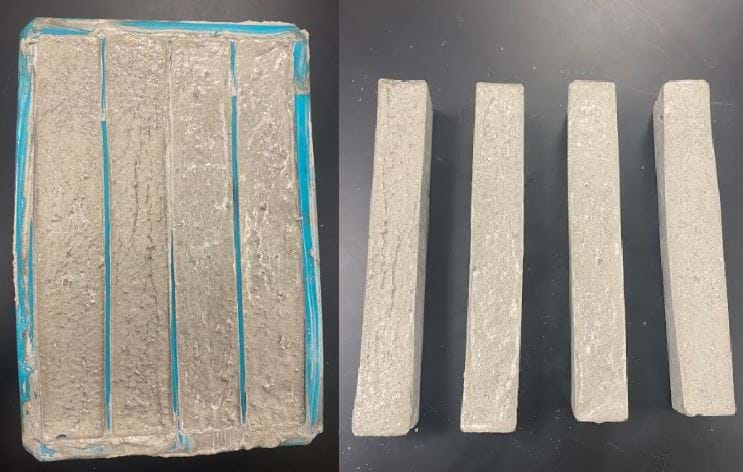

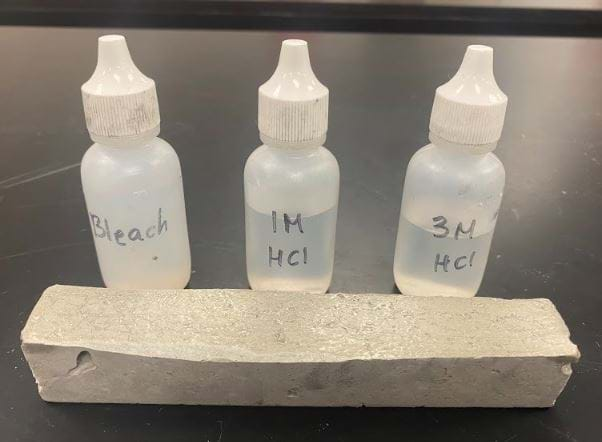

Each group makes two concrete samples in silicone ice molds. Once the sample has cured they can be easily removed from the molds. - Leave the molds in an undisturbed location to set for 2 days minimum.

Part 2: Testing Concrete Composites

- Follow the Lab Station Directions to test different physical and chemical properties of the concrete composites.

- Use the following images, to help with lab station set-up.

Part 3: Improving Concrete Composites

- Have students remake their concrete composites but this time they will change the composition to improve one of the properties being tested based on what samples performed better in the class combined data.

Vocabulary/Definitions

chemical change: An often-irreversible reaction that changes the chemical composition of the substance creating something new.

chemical property: A property where a chemical change has to occur to be observable.

compounds: Two or more elements chemically combined. Can only be chemically separated.

element: Only one type of element. Cannot be physically or chemically separated. Can be found on the Periodic Table.

gas: Gas is one of the three states of matter. The molecules in a gas expand freely to fill the whole of a container, so it has no definite shape and no definite volume.

heterogeneous mixture: A mixture that is visibly different in appearance throughout the mixture, so the different parts are easily distinguishable.

homogenous mixture: A mixture that has the same appearance and properties throughout the mixture. Also known as solutions.

liquid: Liquid is one of the three states of matter. A liquid is a nearly incompressible fluid that has no definite shape but has a constant volume.

physical change: An often-reversable change, where matter changes form but keeps the same chemical composition.

physical property: A property that describes matter.

solid: Solid is one of the three states of matter. The molecules in a solid are closely packed together so solids have definite shape and volume.

Assessment

Pre-Activity Assessment

Pre-Assessment: In the Concrete Composites Lab Worksheet there are three open-ended questions that asks students to engage their prior knowledge of states of matter and types of matter. It also has students hypothesize on if they think certain processes in concrete creation are physical or chemical changes.

Activity Embedded (Formative) Assessment

Formative-Assessment: In the Concrete Composites Lab Worksheet, there are four questions that students complete as they perform the lab. It has students differentiate the properties being tested as physical or chemical, then the physical properties only into quantitative, qualitative, intensive, and extensive. This section also includes the table where the students will write their observations and measurements that they collect while performing the lab.

Post-Activity (Summative) Assessment

Post-Assessment: In the Concrete Composites Lab Worksheet, there are two open-ended assessment questions that ask students to identify if two of the tests they performed was an observation of a physical or chemical change and how do they know.

Making Sense Assessment: In the Concrete Composites Lab Worksheet, there are five open-ended assessment questions that ask students to draw conclusions from the class data and make a claim about the relationship between the composition of the composite to the density, wettability, and strength. It also has students rethink their own composite and come up with a plan on how to improve the results for their composite during the second round of testing.

Investigating Questions

Why are certain materials better suited to different tasks?

For example: Why are pencils made of wood? Why are chairs made of plastic? Why are windows made of glass?

Safety Issues

- Use eye protection while conducting the Strength Test and Reactivity to Bleach and Hydrochloric Acid Test.

- Use gloves while conducting the Reactivity to Bleach and Hydrochloric Acid Test.

- Bleach and hydrochloric acid should be washed off the composite sample thoroughly before performing any other tests on the sample.

- Excess bleach and hydrochloric acid should be disposed of in the hazard container not the drain.

- If using carbon black for composites, wear gloves and goggles when handling samples as it is an irritant.

- If using wood/plastic/metal shavings, wear gloves and goggles while creating composites as shavings can be sharp.

- After performing tests students should wash hands thoroughly with soap and water.

Activity Scaling

- For lower grades, focus on creating the concrete samples to explore the differences between states and types of matter.

- For upper grades, have students explain scientific reasons why their sample may not have performed the best. Give them multiple attempts to improve their samples. Focus on a particular property to improve on for the class and make it a competition to see which group can create the best performing sample for that property.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students create beams using Laffy Taffy and water, and a choice of various reinforcements (pasta, rice, candies) and fabricating temperatures. Student groups compete for the highest strength beam and measure flexure strength with three-point bend tests and calculations.

Over several days, students learn about composites, including carbon-fiber-reinforced polymers, and their applications in modern life. This prepares students to be able to put data from an associated statistical analysis activity into context as they conduct meticulous statistical analyses to evalua...

Students combine paper strips to measure how much gravitational force the paper can withstand by adding masses to the combined paper strips until they tear. Students compare the strength of one paper strip versus the combination of two, three, four, and five strips. Students cut out paper strips and...

Copyright

© 2023 by Regents of the University of Colorado; original © 2022 University of HoustonContributors

Aerielle Rodriguez; Francisco Carlos Robles Hernandez; Arti RaniSupporting Program

Research Experience for Teachers (RET), University of Houston College of Technology, National Science FoundationAcknowledgements

This curriculum was developed under National Science Foundation RET grant no. 1855147— Research Experience for Teachers in Advanced Design and Manufacturing at the University of Houston. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: August 24, 2023

User Comments & Tips