Quick Look

Grade Level: 8 (6-8)

Time Required: 11 hours 15 minutes

(five 50-minute classes per week x 3 weeks)

Expendable Cost/Group: US $10.00 This activity uses some non-expendable (reusable) items, such as computers, fabrication tools, and a wide variety of fasteners and construction materials (specified by the students); see the Materials List for details.

Group Size: 3

Activity Dependency: None

Subject Areas: Problem Solving, Science and Technology

NGSS Performance Expectations:

| MS-ETS1-1 |

| MS-ETS1-2 |

| MS-ETS1-4 |

Summary

Students are given a biomedical engineering challenge, which they solve while following the steps of the engineering design process. In a design lab environment, student groups design, create and test prototype devices that help people using crutches carry things, such as books and school supplies. The assistive devices must meet a list of constraints, including a device weight limit and minimum load capacity. Students use various hand and power tools to fabricate the devices. They test the practicality of their designs by loading them with objects and then using the modified crutches in the school hallways and classrooms.Engineering Connection

Engineers continually solve problems and devise creative solutions during the course of their careers. What kinds of problems? Are they the people who design smartphones, flat screen televisions and electric engines for automobiles? Yes—all that and more! For example, people are living more productive and longer lives today because of the work of biomedical engineers who develop assistive technologies, such as wheelchairs, contact lenses, eye surgery laser equipment, replacement limbs, diagnostic testing equipment, medicines and all sorts of new medical technologies.

Learning Objectives

After this activity, students should be able to:

- Solve an open-ended design problem.

- Use the engineering design process to solve a problem.

- Develop multiple solutions to a design problem.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: | Models of all kinds are important for testing solutions. Alignment agreement: The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: | |

Common Core State Standards - Math

-

Construct and interpret scatter plots for bivariate measurement data to investigate patterns of association between two quantities. Describe patterns such as clustering, outliers, positive or negative association, linear association, and nonlinear association.

(Grade

8)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Make two-dimensional and three-dimensional representations of the designed solution.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Refine design solutions to address criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Math

-

Construct and interpret scatter plots for bivariate measurement data to investigate patterns of association between two quantities. Describe patterns such as clustering, outliers, positive or negative association, linear association, and nonlinear association.

(Grade

8)

More Details

Do you agree with this alignment?

Massachusetts - Science

-

Identify and explain the steps of the engineering design process, i.e., identify the need or problem, research the problem, develop possible solutions, select the best possible solution(s), construct a prototype, test and evaluate, communicate the solution(s), and redesign.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Demonstrate methods of representing solutions to a design problem, e.g., sketches, orthographic projections, multiview drawings.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Describe and explain the purpose of a given prototype.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Identify appropriate materials, tools, and machines needed to construct a prototype of a given engineering design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain examples of adaptive or assistive devices, e.g., prosthetic devices, wheelchairs, eyeglasses, grab bars, hearing aids, lifts, braces.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Materials List

To share with the entire class:

- computers with Internet access and Microsoft PowerPoint software

- pencils and paper or notebook

- measuring rulers or tape measures

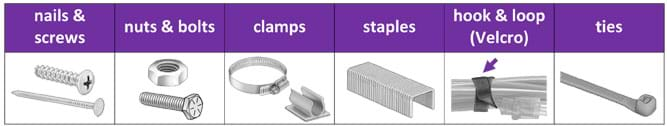

- materials and fasteners for device fabrication, such as various woods, plastics, metals, cardboard and fabric, string, rope, nails and screws, nuts and bolts, staples, clamps, Velcro, zip ties, etc., as specified by the student groups*

- tools for cutting, shaping, forming, joining, fabricating, assembling and finishing designs, such power/hand saws and drills, hammers, screwdrivers, drills, duct tape, glue suitable for the materials, sewing machine or needles and thread, etc.

- scale, for measuring weight up to ~5 pounds

- pair of crutches, one per group (if enough available)

- safety glasses, at least one pair per group, depending upon tools used

- ear protection, can be shared among groups, depending upon tools used

- Engineering Design Process Pre-Activity Test, one per person

- Steps of the Engineering Design Process Visual Aid (as a PowerPoint slide or handout)

- Project Design Criteria (as a PowerPoint slide or handout)

- Assistive Device Project Research Handout, one per person

- Materials Properties Research Handout, one per person

- Engineering Design Process Post-Activity Test, one per person

* Note: For this project, students generate their own list of materials (and tools) and are given no restrictions on the type of materials they choose for their designs other than meeting the project constraints for weight and safety, which naturally serve to minimize the size and amount of materials necessary for the activity. Optional idea: Invite students to bring in their own materials to supplement the teacher-provided materials. Be sure to specify whether it is permitted for students/parents to buy materials or limit their contributions to recycled materials.

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/wpi_crutches_activity] to print or download.Introduction/Motivation

(In advance, administer the pre-activity test, which asks students to place the steps of the engineering design process in the correct order; give this same test at activity end.)

Have you ever had an injury of your leg or foot that required you to use crutches for a few days, or maybe weeks or months? What was it like to use crutches? (Direct students to conduct a think-pair-share on this topic, as described in the Assessment section. Then listen to a few student stories.) Even if you have not used crutches yourself, you have probably seen or known someone who has used them.

Now, imagine that you need to use crutches during the school year when you cannot just lounge around at home all day recuperating. Living a somewhat normal life with your injury is important, because life does not stop when you get hurt. You would need to figure out a way to get around on your crutches all day, to and from school and from class to class, using both of your arms and hands to manipulate the crutches and still carrying anything you needed for the day. What might your needs for your school day be? (Listen to student ideas.) Perhaps books, binders, notebooks, pens, pencils, calculator, and maybe even keys, a cell phone and your lunch!

Another consideration is that in many schools, backpacks are not allowed in classes. How would you carry these supplies if your hands are not free and a backpack cannot be used? It means that you would need a device to assist you when carrying the things you need each day to class. Let's get started brainstorming ideas to solve this problem.

Procedure

Background

The focus of this design project is the application of the engineering design process (EDP) in order to develop prototype assistive devices to meet a specific design challenge. Thus, teachers should have a good working knowledge of the EDP in order to prepare students adequately. The EDP framework provided in the Steps of the Engineering Design Process Visual Aid is from the TeachEngineering curriculum framework. Throughout the activity, have student groups closely follow the EDP steps.

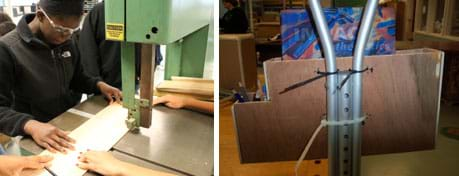

This design project requires the use of a general fabrication shop or, at a minimum, an assortment of hand and power tools to support students' designs and material choices.

It is helpful if teachers have some knowledge of material properties in order to guide students when questions or problems arise during the materials selection stage of the project. Likewise, having a general knowledge of the various kinds of fasteners available is also helpful since students will need to determine ways to securely fasten their completed devices onto the crutches.

Make students aware of pertinent terminology. Materials are the substances or "stuff" from which items are made. A materials property is its quality or trait. Example materials properties include: rough, smooth, hard, soft, strong, flexible, brittle, rigid, elastic, conductor, insulator, heavy, light (weight), durable, inexpensive. For example, glass is fragile, and something brittle is easily damaged or destroyed. When designing something new, good material choices are those selected because they have physical properties that support the purpose of the item and the conditions the item will encounter.

Fasteners are items that hold or join together two or more materials. Fastener examples include: nails and screws, nuts and bolts, clamps, clips, pins, staples, hook and loop (Velcro), tape, twist ties, and zip ties. While glues and tapes are considered adhesives, they also may serve as fasteners to hold or join materials together.

Before the Activity

- Gather materials and make copies of the EDP Pre-Activity Test, Assistive Device Project Research Handout, Materials Properties Research Handout, and EDP Post-Activity Test, one each per person.

- Prepare the following attachments either as PowerPoint slides or student handouts: Steps of the Engineering Design Process Visual Aid and Project Design Criteria.

- If showing PowerPoint slides, have a computer and projector ready to use.

- As examples to show students, gather together an assortment of materials or fasteners that you anticipate students might need during the project, such as the suggestions in the Materials List. If you do not have access to a wide variety of materials or fasteners, prepare an example list of them from which students can consider and choose. In addition, decide whether or not to permit students to bring in their own materials.

- Have available a pair of crutches for students to examine in order to help get ideas flowing right away.

- If desired, determine in advance how to divide the class into work groups of two or three students each.

- After Day 3, be ready to go shopping to make all reasonable material requests available for students.

With the Students—Day 1

- Administer the pre-activity test, which asks students to place the steps of the engineering design process in the correct order (this same test will be given post-activity).

- Then review and/or introduce the steps of the engineering design process (EDP), referring to the visual aid as necessary. Direct students to copy the steps into their notebooks. The basic steps are: identify the need or problem, research the need or problem, develop possible solutions, select the best possible solution, construct a prototype, test and evaluate the prototype solution, redesign as necessary. The process is cyclical and may begin at, and return to, any step.

- Introduce the engineering challenge to the class by presenting the Introduction/Motivation content.

- Use the Project Design Criteria to present the problem statement: Design a device to enable a person on crutches to carry books and small objects.

- Connect the problem statement to the EDP step 1: identify the need or problem. Explain that it is important to clearly identify the statement of need before design can begin.

- Use the Project Design Criteria to introduce the project constraints. Direct students to copy the constraints into their notebooks. The device must:

- Be safe to use.

- Weigh less than 2 pounds (~1 kg).

- Carry a minimum of 4 pounds (~2 kg).

- Attach to a pair of crutches (or an individual crutch).

- Be completed in three weeks.

With the Students—Day 2

- Divide the class into work groups of two or three students each.

- Tell students that they are beginning step 2 of the engineering design process: research the need or problem.

- Direct students to use computers with Internet access to complete the two guided research handouts. What they learn from the research is important and relevant because as they begin working on their designs, ideas and decisions about materials will be based partly on the physical properties of specific materials. Project constraints will also drive decisions about materials, for example, heavy, brittle, and unsafe materials should not be selected.

With the Students—Day 3

- Students begin EDP step 3 to imagine possible solutions by brainstorming and designing possible carrying devices. Remind them to make no final design decisions right away; this is the time for groups to explore and build off ideas contributed by every team member (called brainstorming), discuss the pros and cons of functionality and materials, and agree as a team on a final "best" design solution that meets all the constraints (EDP step 4: select the best possible solution).

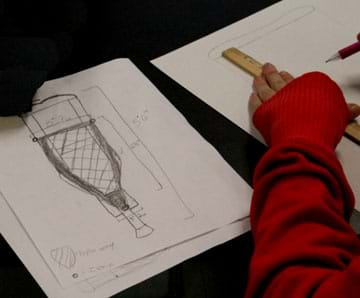

- Have groups create drawings of their devices (perhaps at half-scale) that include descriptions such as dimensions, materials and fasteners.

- As students begin to consider and identify materials for their prototype devices, direct them to list the materials required by their designs, including details of how many or how much for each item. Have students calculate the total amount of material(s) to be used in their designs. For example, have them weigh a known amount of a material (such as a 2-in2 piece of polycarbonate) to determine its weight per area amount, and do this for all materials (cardboard, aluminum, wood, etc.). From these amounts, they can estimate the weight of their prototype devices to make sure to stay under the weight constraint and to know how much material(s) is needed.

- Have groups meet one-on-one with the teacher to review the plans (drawings and lists) for their devices. Give design approval to affirm that final designs meet the constraints.

Note: Consider your available supplies and/or shopping restrictions. Make every attempt to provide all reasonable material requests for students. If designs do not meet all the constraints or require unreasonable materials and unavailable tools, direct students to steps 3-4 to rethink the design possibilities and prepare a revised "best" design.

With the Students—Day 4

- Have groups continue designing and/or begin building their prototypes (EDP step 5) once all plans to meet the design criteria are satisfied.

- Provide safety guidelines and instructions for correct use of tools and equipment as necessary, since not all groups will use all resources. Remind students using power tools to wear safety glasses and/or ear protection.

- Work with the student groups to review/approve designs as they develop.

- Verify that a design meets the weight constraint by having students weigh the final materials, fasteners and other components before attaching them to a crutch.

Depending on the tools available, students gain new skills while creating their prototype devices. This student prototype carrying device was zip-tied to a crutch.

With the Students—Days 5-10

- Have groups continue to build the prototypes and move into the test and evaluation phase (EDP step 6) during which they evaluate and improve their prototypes to best meet the design criteria. Part of this step includes determining what sorts of tests and measurements to conduct in order to evaluate and evolve the prototype design. Expect students to create and implement logical test and evaluation ideas. If guidance is needed, refer to the ideas provided below:

- Test to see how much weight the device can hold, using weights and actual items.

- Verify that a design meets the weight constraint by weighing the final device materials, fasteners and other components before attaching them to the crutch.

- Once attached to a crutch, load the device with 5 pounds (~2.3 kg) of weight, then use the device to determine the efficiency of design.

- Loaded with weight, does the crutch(es) hold the device securely with the chosen attachment method? For example, sometimes the choice of string, rope or tape to attach devices is not strong enough to prevent devices from swinging during use.

- Is the device located on the crutch(es) so that it does not create problems during use? For example, a device located too low on a crutch can create a pendulum effect, making it difficult to walk.

- Ongoing evaluation of designs against the objectives and constraints is essential. Expect prototype testing and evaluating to result in ongoing modifications to the original designs. Much can be learned by testing, so encourage students to make calculations and do many rigorous tests. Direct students to take notes to document their tests, results, observations and evaluations, which helps during the design process so they can refer to them for clarification as the design evolves and improves. In addition, the results from evaluations can suggest modifications that are worthwhile redesign ideas.

- Support the groups by acting as a lab monitor to help with supplies and materials, assist with and troubleshoot any problems that arise, and monitor student use of tools, machines and the shop area.

- Expect groups to finish their prototypes at different times due to the variations in design complexity and focus.

- As the prototypes are completed, evaluate them against the original constraints. Use the suggested rubric for grading. Use a scale to measure the device weight and the weight carried. Observe the device in use to judge its effectiveness and safety.

- Have students take photographs of their finished prototype devices, both in use by students and with close-ups of key features.

With the Students—Day 11

- As step 7 of the engineering design process, ask groups to develop at least one "redesign" alternative solution that would provide improvement or additional features. Often, good ideas for redesigns (or entirely different design solutions) come from the testing and analysis stage, so prompt students to think back to what they learned and observed during testing (suggest they refer to their notes from days 5-10). Mark or identify the design alternatives on the original design sketches.

With the Students—Days 12-13

- Direct groups to prepare presentations that communicate project results. Require presentations to follow the steps of the engineering design process, for example: title slide, identify problem, recap research, show design solutions, remaining suggestions for improvement, etc. Include sketches and photographs.

- Have groups show their presentations at project end, or invite families to an "Engineering Night" or end-of-day "Design Expo" to showcase their work.

- Administer the post-activity test, as described in the Assessment section.

Vocabulary/Definitions

assistive device: A device designed or adapted to help people with physical or emotional disorders to perform actions, tasks and activities.

biomedical engineering: The application of engineering principles and techniques to the medical field.

design: (verb) To plan out in systematic, often graphic form. To create for a particular purpose or effect. For example, to design a building or a device. (noun) A well thought-out plan.

disability: A physical or mental condition that limits a person's movements, senses or activities; a handicap.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. This is a cyclical process that requires engineers to test and redesign prototype devices as often as it takes so they end up with reliable finished products.

fastener: Something that holds or joins two or more materials together.

material: The substance or "stuff" from which something is made.

problem solving: The process of working through details of a problem to create a solution.

property: A quality or trait belonging to an individual or thing.

Assessment

Pre-Activity Assessment

Pre-Activity Test: Administer the Engineering Design Process Pre-Activity Test, which asks students to place the steps of the engineering design process in the correct order.

Think-Pair-Share: Ask student pairs to share what they know about how they, or someone they know, managed to get around on crutches and what they did to carry things. Randomly select groups to share their experiences. Discuss ideas as a class.

Activity Embedded Assessment

Spot Check Questioning: During Days 3-13, as students work through the EDP steps, spot check their comprehension of the objective/problem statement, project criteria/constraints, and where they are in the design process. Example questions:

- Why is it important to identify the problem? (Example answers: It gives focus and clarity to the process of design and problem solving. It drives all decision making during the design process.)

- What is the purpose of a prototype? (Example answer: It is a model that can be tested to see if the design functions as intended. You can learn a lot from failures. Usually it takes many prototype "iterations" to obtain a good design.)

- How do you know if a design works? (Example answer: It achieves the stated objective and does not violate any of the constraints.)

Tests & Evaluations: While students are building their prototype designs, their ongoing testing and evaluation serves as assessment of the success of their design work in meeting the objectives and constraints, as well as a measure of their engagement in the project. Encourage students to do many tests, such as determining how much weight the device can hold and how fast a person can "crutch" (that is, walk with crutches) with a weighted device. Conducting rigorous tests and collecting comparative data on interim and alternate designs helps to clarify the results. If desired, collect and review students' notes on their tests and results.

- As a class, create a graph of device weight vs. maximum amount of weight that the device can hold (for each group). Then discuss the trade-offs that are made for each type of device (i.e. a lighter device is easier to carry around but can't hold as much weight, whereas a heavier device can carry more weight but isn't as easy to carry on crutches).

Post-Activity Assessment

Prototype Evaluation: Use the Carrying Device Project Rubric to assess groups on their completed devices against the three project learning objectives: 1) solution solves an open-ended design problem, 2) student applied engineering design process, and 3) student developed multiple solutions.

Post-Activity Test: Administer the Engineering Design Process Post-Activity Test (same as the pre-activity test), which asks students to place the steps of the engineering design process in the correct order. Compare students' pre/post scores to gauge their mastery of the concepts.

Safety Issues

- Provide training for use of hand and power tools.

- Have students wear safety glasses and/or ear protection when using hand or power tools.

- Clarify expected behavior in the shop, for everyone's safety.

Activity Scaling

- For upper grades, more advanced students or classes with access to computers with CAD software, have students create their design drawings or plans using a 3D modeling program such as Google SketchUp.

- To heighten the challenge for more advanced students, add a materials budget (a cost limitation) in addition to the safety, weight, load and time constraints.

- If a machine shop is available for student use, scale up the project materials, skill-building fabrication instructions and prototype quality expectations to take advantage of the more advanced tools.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Student teams are challenged to design assistive devices that modify crutches to help people carry things such as books and school supplies. Given a list of constraints, including a device weight limit and minimum load capacity, groups brainstorm ideas and then make detailed plans for their best sol...

References

Steps of the Engineering Design Process. Last updated May 1, 2001. Archived Information, Strand 4: Technology/Engineering, Science and Technology/Engineering Curriculum Framework, Massachusetts Department of Elementary & Secondary Education. Accessed November 21, 2013. (source of visual aid) http://www.doe.mass.edu/frameworks/scitech/2001/standards/strand4.html

Copyright

© 2013 by Regents of the University of Colorado; original © 2013 Worcester Polytechnic InstituteContributors

Thomas Oliva; Terri Camesano; Kristen BilliarSupporting Program

Inquiry-Based Bioengineering Research and Design Experiences for Middle-School Teachers RET Program, Department of Biomedical Engineering, Worcester Polytechnic InstituteAcknowledgements

This digital library content was developed by Worcester Polytechnic Institute under National Science Foundation grant number EEC 1132628 in collaboration with the Worcester Public Schools. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: October 20, 2020

User Comments & Tips