Quick Look

Grade Level: 11 (9-12)

Time Required: 2 hours 30 minutes

(three 50-minute class periods)

Expendable Cost/Group: US $20.00 This activity also uses some non-expendable (reusable) items; see the Materials List for details.

Group Size: 4

Activity Dependency:

Subject Areas: Biology, Chemistry, Life Science, Science and Technology

NGSS Performance Expectations:

| HS-ETS1-2 |

| HS-ETS1-3 |

Summary

Students experience the engineering design process as they design and construct lower-leg prostheses in response to a hypothetical zombie apocalypse scenario. Like the well-known Apollo 13 story during which engineers were challenged to fix the crippled spacecraft with limited supplies in order to save astronauts' lives, in this activity, students act as engineers during an imaginary disaster in which a group member's leg was amputated in order to survive a zombie attack. Building on what they learned and researched in the associated lesson, they design and fabricate a replacement prosthetic limb using given specific starting material and limited additional supplies, similar to how engineers design for individuals while working within constraints. A more-advanced scenario challenges students to design a prosthesis that is able to provide a more-specific movement function.Engineering Connection

Engineering teams typically follow the steps of the cyclical engineering design process to guide them as they develop new solutions, products and systems. Engineering inventions and innovations are the result of specific, goal-directed work, which includes clear identification of the criteria and constraints of a problem. Engineers and medical doctors design new materials and devices to create prostheses that enable amputees to become mobile and even perform specific activities, like running and swimming. In many cases, engineers only have limited supplies to design and build a necessary device. The Apollo 13 story is an example of what engineers can accomplish when they work together to solve life-threatening problems and refuse to fail.

Learning Objectives

After this activity, students should be able to:

- Demonstrate the use of the engineering design process and the importance of testing prototypes.

- Explain how forces that the body incurs affect the design of a device.

- List factors that need to be considered when designing prostheses.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Conduct research to inform intentional inventions and innovations that address specific needs and wants.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Cite examples of the criteria and constraints of a product or system and how they affect the final design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Texas - Science

-

communicate and apply scientific information;

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each student needs:

- Design Your Own Prosthesis Worksheet

- (alternate or additional project) Design Your Own Prosthesis Worksheet Extended Version

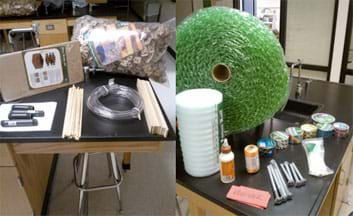

Each group needs ONE of following starting materials (see Figure 1):

- ½ or 1 package of cardboard interlocking packing pieces, such as the 1 cu ft package at Home Depot

- 1 moving glass divider kit (cardboard interlocking divider pieces), such as the kit at Home Depot

- ~4 pieces of PVC pipe, perhaps 6-in and 4-in lengths; provide pieces that do not fit together (different widths) to create more of a challenge

- ~20 wooden dowel rods; perhaps ¼ in or ½ in diameter size and ~16 in long

- ~7 wooden flat sticks; perhaps ¼ in thick x 2 to 4 in wide and ~16 in long

- ~10 ft vinyl tubing; such as ½ in x 3/8 in size

Note: For the starting materials, provide supplies of cardboard, vinyl tubing, PVC pipe pieces, wooden dowels and wooden flat sticks. The materials list suggests some example products and specific dimensions and amounts for guidance purposes; feel free to get what makes sense for your class at local hardware stores, online and/or recycling bins.

Supplies for the barter table (see Figure 1):

- bubble wrap; use for multiple class periods; barter for 5-ft piece; such as from a ½ in x 12 in x 75 ft roll

- dish foam (thin plastic padding material); use for multiple class periods; barter for 4-in piece; such as from a 1/16 in x 12 in x 50 ft roll

- zip ties; use for multiple class periods; barter for 4 zip ties; such as from a 100-pack of 8-in cable ties

- colored/patterned duct tape, one roll per group; every group may buy one and once they run out groups must purchase use of the silver duct tape; such as 1.88 in x 10 yds neon stripes duct tape roll

- silver duct tape; one per class period; use after all other duct tape rolls have been purchased; barter for the use of it; must be shared between groups that purchase use; such as 1 7/8 in x 55 yd duct tape

- carriage bolts; may need 4-6 bolts per class; barter for 1 bolt; such as 8-inch or 5-inch zinc bolts

- wood glue; 1 bottle per class period; barter for use of the glue; must be shared between groups that purchase use; such as 8 oz bottle of Gorilla wood glue

- mason line/string (a strong, durable string); use for multiple class periods; barter for use of the string; must be shared between groups that purchase use; such as #18 x 425 ft orange polypropylene twisted mason line

Note: For the barter table materials, the above are suggested items, but feel free to provide what makes sense for your class and set your own parameters for the specific amounts of materials provided during the bartering.

To share with the entire class:

- Voucher Questions, printed out and cut up so one question per strip; make enough for four questions per group (24 different questions provided on attachment)

- bucket or bowl or some container to hold all the vouchers

- (optional) saw and/or drill, if teachers needs to cut PVC pipe, wooden dowels, flat sticks

- scissors

- rulers or tape measures

- iPads or computers with PowerPoint® or Keynote® software, for group presentations

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uoh_pirates_lesson01_activity1] to print or download.Pre-Req Knowledge

A basic understanding of bones and muscles is useful for students. Knowledge of basic physics with forces is helpful for demonstrating specific requirements of prostheses.

Introduction/Motivation

Through the years, many different kinds of prostheses have been fashioned. Early on, simple peg legs were much appreciated to help people regain mobility and walking capabilities. Pirates became the symbol of peg leg use. During the 20th century's World Wars, medical care improved, saving more lives, sometimes at the expense of damaged and amputated body parts. During tragic times, makeshift solutions are found to save lives. People are immobilized for transport to hospitals, and damaged bodily systems are fixed with whatever limited supplies are available.

For this activity, you are acting as engineers during a time in which supplies and resources are limited. You must use your ingenuity and the engineering design process to design and fabricate prosthetic trans-tibial limbs capable of enabling a person to walk.

Procedure

Before the Activity

- Gather materials and make copies of the Design Your Own Prosthesis Worksheet, one per person.

- Prepare the voucher slips, enough for four per group. In the context of the hypothetical scenario, a voucher represents food, which is what teams use to barter for materials. Instead of food, students apply what they learned during the associated lesson to answer questions that relate to prostheses, enabling teams to use earn the vouchers to obtain materials. To prepare the voucher slips, cut apart the Voucher Questions document into single-question slips; the attachment contains 24 different questions; put the slips into a bucket or bowl from which students can randomly choose. For the answers, refer to the Voucher Questions Answer Key.

- Set out the available starting materials on separate tables or areas in the classroom (see Figure 1).

- Set up a barter table with all of the supplies that students can barter for during that class period (see Figure 1).

With the Students

- Present the Introduction/Motivation content and conduct the pre-activity discussion (described in the Assessment section).

- Divide the class into groups. Either assign each group ONE starting material or let them choose one.

- Read aloud the hypothetical scenario (also on the worksheet).

It's finally happened. The zombie apocalypse is here. You are among a group of survivors who have managed to remain uninfected. However, during a food search, you and your group found yourselves in an intense fight through a horde of zombies. One person in your group was bitten on the ankle. To keep the infection from spreading and the person from becoming one of the living dead, your group made the difficult decision to quickly amputate the leg below the knee. Thankfully, the person has made a full recovery and now needs some sort of prosthesis to replace the lost limb so everyone can be mobile in order to stay away from the hungry zombies!

- Explain the activity rules: Since this is the zombie apocalypse, resources and supplies are scarce. To begin, each group gets ONE starting material—cardboard, cardboard packing, dowel rods, PVC pipe, wooden sticks OR vinyl tubing. To obtain other materials, your team barters with a group of survivors who prepared for the apocalypse long before it happened (the teacher). No trading is permitted amongst the groups for starting materials, only bartering with the teacher. Since each group has only so much to barter with, make sure your designs are well thought out before any construction begins. Once groups have completed fabrication of the prosthetic limbs, they will be tested. For the test, one group member uses the limb to walk 20 feet without help from anyone else. Just to be safe, always have two other members of your group walk alongside the tester to protect him/her from potential injuries from a fall during testing. Recap of the activity rules.

- All designs must be seen and approved by the teacher before any bartering can commence.

- No trading between groups, only bartering with the teacher at the barter table.

- Only four vouchers per group. 1 voucher = 1 chance to answer a question = 1 item from the supply table.

- You have three days for the activity.

- On Day 3, each group demonstrates that its prosthetic limb functions correctly by having one unassisted group member walk 20 feet using the replacement limb.

- On Day 3, each group makes a five-minute class presentation to summarize its project.

- Hand out the worksheets and direct students to begin. The worksheet guides groups through the design project activity, essentially following the steps of the engineering design process: ask: identify the need and constraints; research the problem; imagine: develop possible solutions; plan: select a promising solution; create: build a prototype; test and evaluate prototype; improve: redesign as needed. These activities essentially comprise the main steps of the engineering design process.

- Monitor students as they fabricate their designs (see examples in Figure 2). Engage with students at the barter table by taking their vouchers and asking them questions relating to prosthetics before permitting them to take materials. Keep them on task as to the project's criteria and constraints.

- While groups are constructing and testing, have them also prepare a five-minute class presentations to summarize their prosthetic designs. See the Assessment section for suggested presentation requirements.

- During any in-team preliminary testing and the Day 3 final test/demonstration, make sure groups protect their test subject students by having other team members on the sides ready to catch the student testing the prosthesis and keep him/her from falling to the ground.

- As groups test their designs, remind them to document on their worksheets if and why their design prototypes worked or did not work and what changes they would make to improve the design.

- Have student groups make their presentations to the class.

Figure 2. Example finished prosthetic lower-limbs designed and built by students using one starter material and barter table materials.

Vocabulary/Definitions

amputation: The removal of an appendage due to trauma, bacterial infection or life-threatening cause. A traumatic amputation occurs when an appendage is removed as a result of the trauma without medical care, such as a bomb.

amputee: A person with an amputation.

components: The internal working parts of a prosthesis.

composite: A material that is a combination of multiple material components, designed to have specific properties, such as carbon fiber.

constraints: In engineering design, the limitations and requirements that must be considered when designing a workable solution to a problem.

cosmetic prosthesis: A prosthesis that enhances a person's appearance or completeness, but has no functional purpose. For example, a replacement glass eyeball is a cosmetic prosthesis if it does not also restore vision.

cover: As relates to prostheses, material used to cover a prosthesis to make it appear more lifelike.

criteria: In engineering design, the objectives that a final design solution is required to meet.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. Typically, the steps include: defining a problem, brainstorming, researching and generating ideas, identifying criteria and specifying constraints, exploring possibilities, selecting an approach, developing a design proposal, making a model or prototype, testing and evaluating the design using specifications, refining the design, creating or making it, and communicating processes and results.

functionality: As relates to prostheses, the ability of a prosthesis to have a purpose or reason for designing it in a specific way. For example, a wood peg leg has less functionality than a modern prosthetic leg that enables an athlete to run competitively.

interface: The point where a prosthetic device meets a residual limb.

prosthesis: An artificial device, either external or implanted, that replaces or supplements a missing or defective body part, such as a tooth, eye, facial bone, palate, hip, knee joint, leg, arm, hand, etc. May be designed for functional or cosmetic reasons or both. (plural: prostheses)

prosthetics: The surgical, dental and/or engineering specialty concerned with the design, fabrication and fitting of prostheses.

regenerate: (biology) To renew or restore a lost, removed or injured part.

residual limb: The remaining portion of a body's appendage or limb after amputation.

tissue engineering: The use of cells, and biochemical and physiochemical factors to design new biomaterials to replace lost or damaged body materials that have specific biological functions.

transfemoral: A prosthesis that replaces the leg from above the knee (includes the knee, angle, foot and toes).

transhumeral: A prosthesis that replaces the arm from above the elbow (includes the elbow, wrist, hand and fingers).

transradial: A prosthesis that replaces the arm from below the elbow (includes the wrist, hand and fingers).

transtibial: A prosthesis that replaces the leg from below the knee (includes the ankle, foot and toes).

trauma: An event causing severe damage to the body.

Assessment

Pre-Activity Assessment

Group Discussion: As practice for thinking creatively about applying available materials to a specified objective, ask students what materials available in their houses they would use to make a prosthetic limb. Make a list on the board of their ideas.

Activity Embedded Assessment

Worksheet: Have students use the Design Your Own Prosthesis Worksheet to guide them through the activity. Review the sketches and answers on their completed worksheets to gauge their depth of engagement and comprehension. The answer to question #5 (on both worksheets), the steps of the engineering design process experienced in this activity, is:

- Ask to Identify Needs and Constraints.

- Research and brainstorm: Research previous methods of making prosthetic limbs and attachments (done in associated lesson). Brainstorm and pool all your ideas as a team.

- Imagine and design possible solutions: Imagine possible prostheses that can be made with the available materials to meet the given criteria and constraints.

- Plan and choose which design solution is the best.

- Build/construct a prosthetic limb prototype of your design.

- Test your design of a replacement limb prototype under realistic conditions (applied forces).

- Redesign/evaluate your design: Analyze test results for adjustments and design improvements.

Post-Activity Assessment

Presentation: Have each group summarize its engineering design project work in a five-minute presentation to the rest of the class. Require students to answer the following questions: What are the criteria and constraints for your design? What is your design approach? How does it work? What are the pros and cons of your design? What trade-offs did you consider in your design and choice of materials? Why did the design work/not work? What design modifications would you make so that it works better?

Investigating Questions

- Which starting materials might be easier to work with than others?

Safety Issues

- Beware of getting splinters with the wooden dowels and flat sticks.

- If students use scissors to make holes in the PVC pipe, make sure they do not twist through the pipe and into the palms of their hands.

- When testing the designs, make sure two other group members stay on either side of the student with the prosthesis to ensure that if the design fails, s/he will be caught instead of falling to the ground.

Troubleshooting Tips

The attachment of a prosthesis to a limb can be the most difficult for students. Suggest that students place the device underneath the knee in order to fully support the body weight (see examples in Figure 2). Otherwise, the prosthetic limb will bend significantly and/or buckle and fail.

The vinyl tubing is the most challenging starting material and groups with this material may need extra support or vouchers to be able to acquire additional materials to make their replacement limbs functional.

Activity Extensions

Have students design prostheses for people who need to perform specific functions, such as swimming or climbing, as presented in the Design Your Own Prosthesis Worksheet Extended Version. In this alternate/additional/more advanced scenario, students imagine themselves surviving on an uninhabited island after a shipwreck where groups are challenged to design prostheses for one of five different amputee requirements: below-knee swimmer, above elbow right arm, both legs below the knee, above-knee right leg runner, and left hand that needs to climb and grip.

Assign students to research and investigate currently available below-the-knee prosthetic limbs and form opinions on which would be the most beneficial—their pros and cons for different amputee situations.

Activity Scaling

- For lower grades, use only the cardboard starting materials or provide materials that are easier to work with than the others in the Materials List.

- For higher grades, have students conduct the extended version of the activity, as described in the Activity Extensions section, using the Design Your Own Prosthesis Worksheet Extended Version.

- For higher grades, do not limit groups to a specific starting material; instead, make all materials available at the supply table. Monitor that students are not hoarding all the supplies or impose some other material limitation.

Additional Multimedia Support

It may be helpful to show students this diagram of four suspension systems for leg prostheses: cuff strap with waist belt and billet, cuff strap, neoprene sleeve, thigh corset with waist belt and fork strap, at The Health Science's website at http://thehealthscience.com/thsattachs/904911/111907350034002.jpg.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are introduced to prosthetics—history, purpose and benefits, main components, main types, materials, control methods, modern examples—including modern materials used to make replacement body parts and the engineering design considerations to develop prostheses. They learn how engineers and ...

Students extend their knowledge of the skeletal system to biomedical engineering design, specifically the concept of artificial limbs and joints. Students relate the skeleton as a structural system, focusing on the leg as structural necessity. They learn about the design considerations involved in t...

Copyright

© 2015 by Regents of the University of Colorado; original © 2014 University of HoustonContributors

Megan Ketchum, Andrea LeeSupporting Program

National Science Foundation GK-12 and Research Experience for Teachers (RET) Programs, University of HoustonAcknowledgements

This digital library content was developed by the University of Houston's College of Engineering under National Science Foundation GK-12 grant number DGE 0840889. However, these contents do not necessarily represent the policies of the NSF and you should not assume endorsement by the federal government.

Last modified: August 28, 2020

User Comments & Tips