Quick Look

Grade Level: 11 (10-12)

Time Required: 11 hours 15 minutes

(12-15 class periods)

Expendable Cost/Group: US $7.00

Group Size: 3

Activity Dependency: None

Subject Areas: Biology, Life Science, Measurement, Problem Solving, Reasoning and Proof, Science and Technology

NGSS Performance Expectations:

| HS-ETS1-3 |

| HS-LS1-2 |

Summary

The traditional plaster cast we use to heal a broken bone needs an overhaul! This cast design is over 250 years old and is heavy, stinky, and cumbersome. Students design a new device for a client with a broken ankle as they engineer a better cast. This activity mimics what a biomedical or materials engineer needs to consider when they must meet medical “must-haves” and address client needs.Engineering Connection

Biomedical engineers tackle innovation under the constraint of medical necessity. This activity asks students to design to the client/patient needs and the medical requirements of bone healing. Exploration of bone cells, nutritional requirements and vascular capability are combined with material selection, weight limits, and safety requirements that engineers typically deal with. Students investigate electricity, magnetism, the light spectrum as well as the use of different materials (fiber carbon, nylon, plastics) that may be used to build prototypes.

Learning Objectives

After this activity, students should be able to:

- Investigate the action of different bone cell types in the fracture healing process.

- Prioritize medical must-haves and combine with client wants.

- Evaluate different materials to be used in a re-design of the traditional plaster cast.

- Analyze effectiveness of a prototype.

- Communicate new design with classmates/medical professionals.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-LS1-2. Develop and use a model to illustrate the hierarchical organization of interacting systems that provide specific functions within multicellular organisms. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop and use a model based on evidence to illustrate the relationships between systems or between components of a system. Alignment agreement: | Multicellular organisms have a hierarchical structural organization, in which any one system is made up of numerous parts and is itself a component of the next level. Alignment agreement: | Models (e.g., physical, mathematical, computer models) can be used to simulate systems and interactions—including energy, matter, and information flows—within and between systems at different scales. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Optimize a design by addressing desired qualities within criteria and constraints.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Pennsylvania - Science

-

- Compare and contrast scientific theories.

- Know that both direct and indirect observations are used by scientists to study the natural world and universe.

- Identify questions and concepts that guide scientific investigations.

- Formulate and revise explanations and models using logic and evidence.

- Recognize and analyze alternative explanations and models.

- Explain the importance of accuracy and precision in making valid measurements.

- Examine the status of existing theories.

- Evaluate experimental information for relevance and adherence to science processes.

- Judge that conclusions are consistent and logical with experimental conditions.

- Interpret results of experimental research to predict new information, propose additional investigable questions, or advance a solution.

- Communicate and defend a scientific argument.

Do you agree with this alignment?

-

Analyze how cells in different tissues/organs are specialized to perform specific functions.

(Grade

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- laptop

- whiteboard with markers

- scale

- hot glue gun

- worksheets:

- Recipe of a Bone/Deconstruct a Bone Pre-Assessment (individual)

- Sketching Worksheet (one per group)

- Initial Prototype Idea Individual Worksheet (individual)

- Concept Screening and Selection Worksheet (one per group)

- How to Create a Scientific Poster/Video Instructional Worksheet (one per group)

- Grade Sheet for scoring the scientific poster & video (one per group)

For the entire class to share:

- Based on prototype sketches, materials may include:

- adhesives/glues

- beads

- cardboard boxes

- checkers

- electrical tape/duct tape

- foam of any shape/size

- office supplies – rubber bands, push pins, paper clips

- jump ropes

- plastic placemats

- scissors/staplers

- slinky

- wire

- zip ties

- blood pressure cuff or similar pressure gauge for testing (optional)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/upitt-2621-engineering-better-cast-design-activity] to print or download.Pre-Req Knowledge

An understanding of cells and blood vessels.

A basic knowledge of bones.

Familiarity with measurement – weight, dimension, volume.

Basic understanding of the engineering design process.

Introduction/Motivation

Have you ever had a cast? [More than one student will respond, so ask what bone they had broken and ask each to share one complaint about the cast.] For those of you who have had to wear a cast, what were some of the negative aspects of the cast? [List the bone(s) on the board and the complaints. Notice that most fractures occur with the arm bones and leg bones.]

Why do you think arm and leg bones are broken more often than other bones in the body? [Answer: The limbs (appendages) have free movement, so we get our arms and legs twisted and stuck, sometimes breaking the bones if enough force is applied. Bones of the trunk (axial skeleton) like the ribs, sternum and pelvis have limited movement, so they tend to be more difficult to break.]

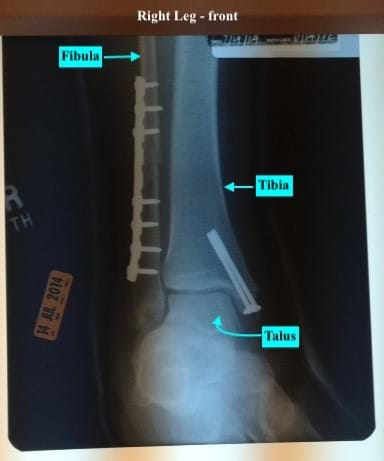

With these issues in mind, let’s take a look this patient’s issue: Patient A suffered an injury while they were riding a horse. The horse got spooked by a snake and reared up. Patient A was thrown off the horse and the horse’s front leg came down on their ankle. Patient A suffered fractures of the tibia, fibula, and talus (see Figure 1 and Figure 2):

Patient A has a cast after surgery, along with a few complaints about the fit of the cast.

Patient A is your client– you will need to redesign the traditional cast so that their medical needs are met, allowing their bones to heal, and that complaints about the cast are addressed as well. This means that you will need to research bone anatomy and how bones heal, brainstorm a new way to heal bones that may be very different from the traditional cast, sketch this new device and build a prototype. Don’t panic – we will break into groups, to foster creativity and collaboration. Teamwork makes the dreamwork and Patient A will need a team to help solve their cast complaints. Good luck!

Procedure

Background

The human skeleton is composed of 206 bones. Sometimes these bones may break or crack, causing a fracture. Broken bones will heal on their own over a few months. To speed up the healing process, a physician may use a cast. A cast can reduce healing time from months to weeks and it will ensure that the bones heal straight. The traditional plaster cast has been used for centuries dating back to the early 1800s in the Napoleonic Wars, so it clearly it is time for a re-design.

There are four different bone cells in the body – the osteoprogenitor, osteoblast, osteocyte and osteoclast that work together to maintain healthy bones. The osteoprogenitor is a bone stem cell, which will become active when the bone is unhealthy or fractured. The osteoblast synthesizes matrix, which refers to the substances that occupy the spaces between bone cells. Matrix in bone is a combination of protein, sugar, fibers, and calcium. The osteocyte is a mature bone cell that maintains matrix and the osteoclast is the cell that dissolves old matrix.

In the case of a fracture, the osteoclast will dissolve damaged matrix, and the osteoprogenitor will transform to an osteoblast in order create new and fresh matrix. Blood vessels will need to bring oxygen and nutrients to the bone cells so that they can break down damaged matrix and replace it with new matrix, so any damaged vessel will also need to be repaired. When brainstorming a new and better “cast” please keep the medical must-haves as priority – blood flow to the site, reconstruction of bone matrix and ensuring the bone will heal straight.

Each group will re-design the traditional cast by following the engineering design process. There are minimal constraints – do no harm to the patient (part of the Hippocratic Oath for physicians) and be able to present a prototype of the design using dollar store materials to represent expensive or unique items that are not available in a classroom.

Before the Activity

- Make copies of the following worksheets:

- Recipe of a Bone/Deconstruct a Bone Pre-Assessment (individual)

- Sketching Worksheet (one per group)

- Initial Prototype Idea Individual Worksheet (individual)

- Concept Screening and Selection Worksheet (one per group)

- How to Create a Scientific Poster/Video Instructional Worksheet (one per group)

- Grade Sheet, for scoring the scientific poster & video (one per group)

- Fill a bin with various dollar store items that may be used to build prototypes.

- Give each group a white board and dry erase markers.

With the Students

Day 1 – Research bone healing and understand the client’s needs

- Go through the Introduction / Motivation.

- Have students use the Recipe of a Bone/Deconstruct a Bone Pre-Assessment.

- Have students perform research or brainstorm as a class the problems associated with traditional casts. (Examples might include: the cast is itchy, the cast is heavy, there is no way to check on the incision at the ankle to see if it is healing, cannot shower with the cast.)

- Pose the question – How would you re-design the traditional cast? Do not have students reply to this question, just think about it for one minute. Do not let students share their ideas with any other person in class. Each student will need to sketch two ideas to share with the group tomorrow, so do not give away a great thought! (Note: keep whiteboard notes available for Day 3 of the activity.)

- Divide the class into groups of three to four students each.

- Groups research and write down the steps in the bone healing process for 10-15 minutes. Use online sources such as:

- What Happens When You Break a Bone? https://www.webmd.com/first-aid/ss/slideshow-break-bone-what-happens

- How Do Broken Bones Heal? https://www.denverhealth.org/blog/2019/09/how-do-broken-bones-heal

- About Casts: https://orthoinfo.aaos.org/en/treatment/about-casts-video/

- What can cause a fracture to have delayed healing? https://www.youtube.com/watch?v=xWMzinAx3Ic

- Look at each group’s list of steps in the healing process. Dig deeper if a critical step is missing. Steps may include:

- Formation of a fracture hematoma at site of fracture.

- Removal of old matrix by osteoclasts.

- Bony/cartilage callus forms on bone, bridge of spongy bone exists – osteoblast activity high.

- Remodeling of bone occurs – spongy bone converted to compact bone.

Day 2 - Sketching

- As a class, review the steps in bone healing after a break. Discuss the importance of blood flow in this process so that nutrients are readily available.

- Have students research medical “must-haves” that any device would need to meet if used to fix a bone fracture.

- Make a list of medical “must-haves” on the board that any device would need to meet if used to fix a bone fracture. (As the list is created, the whole class must either accept or reject each item based on what they know about the skeleton and the healing process. Some answers include:

- Durability - how can my cast protect a patient from themselves or hold up to their abuse

- Cast position - how can I apply my cast without putting too much pressure over certain area?

- Alignment of bone

- Speed of healing by stimulating osteoblast activity

- Hygiene - how can I protect my surgical site from infection? (Look at a cast or an image of one – students should say that the cast immobilizes the bone so that it remains straight. They may suggest that a cast is heavy as a complaint – expand on that point. A cast is heavy because weight stimulates osteoblast activity. The osteoblast cell synthesizes matrix, so we want it to become active to replace the damaged area.

- Pass out the Sketching Worksheet to each student. Ask them to sketch out their 2 ideas for a new “cast” to the boxes labeled “A”. (Note: Anatomy students are familiar with views like anterior, posterior, medial, lateral, etc. If teaching to a biology class or life science class, a sketching primer may be needed. If so, take class time to pass out everyday objects, like a toothbrush, a banana, a stapler, cell phone, and ask each student to sketch the object from 3 views. Ask for a front view, a back view and a side view. This will spark 3D mental modeling that is required of engineers.)

- Break into groups and explain how to complete the Sketching Worksheet. Student one has already sketched their 2 designs. Set a timer for 5 minutes. Pass the worksheet to the person on the right (everyone will have a worksheet) and look at the sketches. Re-sketch and modify that design – add a feature, change a feature or dimension, etc. This is a creative exercise so wild ideas are welcome! Once the 5 minutes have expired, pass the worksheet to the right again to the next person in the group, set a new timer for 5 minutes, re-sketch and modify in the next box, no talking, repeat.

- At the end of this activity, the worksheet will be back to its original owner. Allow 5-7 minutes for the groups to look at the original sketches and the modifications added in the re-sketches and discuss. This is the time to explain ideas, ask questions.

- Each student will select one sketch from the Sketching Worksheet that they want to submit for prototyping. Pass out the Initial Prototype Idea Worksheet to complete as homework.

Day 3 – Concept screening and selection

- Collect the homework from yesterday after addressing any questions.

- Look at the white boards from Day 1 about casts are listed on the white board – add/modify if needed. These are the client “wants” in the design process.

- Pass out one copy per group of the Concept Screening and Selection Worksheet. This worksheet will score four designs against criteria. The final score will determine which design is prototyped and built by the group.

- The worksheet has three medical necessities (bone alignment, osteoblast stimulated, allows for vascularization) already listed that must be included with the new design. The group will add three additional client “wants.”

- Next, each student will submit their sketch on the worksheet and give that sketch a name. The worksheet will have four sketches to be evaluated, one from each group member. (Note: students should use an appendage, arm, or leg. When we break other bones like ribs or pelvis, no cast can be applied because the pressure would impair breathing or digestion. Those bones on the midline of the body will need to heal on their own without a cast. Stick to arms and legs!)

- Score each sketch as (+) if better than the traditional cast, (-) if worse than the traditional cast or (0) if same as the traditional cast. Scoring promotes discussion and explanation of each person’s design among the group. Add up the (+), this determine the winning design that will be built.

- Allow 5 minutes for the group to make a list of dollar store materials that they need to begin prototyping. This can be done on the white boards or on a piece of paper. Teachers should scan the lists for anything unusual that is being requested or impossible to supply, like uranium or a cold laser!

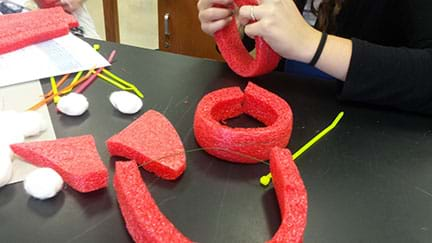

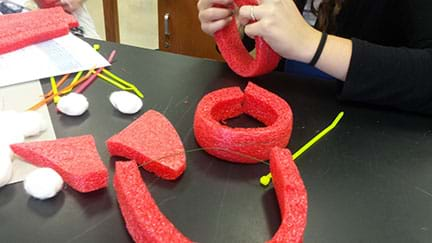

Days 4-8 – Prototyping and testing

- Refer to steps 5-7 of the Engineering Design Process to give students guidance on how to proceed with prototyping design, testing, and improvement.

- Time to build – bring out the dollar store materials, adhesives, office supplies, etc. Each group will build the design that was scored the highest yesterday. This process takes time and requires teacher input daily. Teacher should ask questions like:

- What does this material represent?

- How does this work?

- Does this device meet all medical must-haves? Does it meet client wants?

- Once the prototype is built, testing the device happens. Testing is based on the medical must-haves and client wants. For example, if the client wants waterproof, then the device should be submerged in water and stay intact. Medically, the device should hold the bone in alignment, so testing could be applying pressure manually (or by using a pressure gauge, optional) or flexing the device to determine stability. Groups will struggle with testing and researching metrics/standard values to compare against. Using a laptop to research testing is very helpful.

- Some testing metrics that may be used:

- Water resistance – submerge for 8 minutes in 42.2°C (108°F water) an average time and temperature for a shower)

- Comfort – create a 3-5 question survey and ask wearers to answer

- Alignment of bone – 1 degree off axis or less

- Using a blood pressure cuff or similar gauge on the cast (optional)

Note – a survey can be used as a test. If the client wants comfort, one way to test for comfort is to wear the device and ask a series of questions, rating comfort on a scale of 1-5.

Days 9-12 – Create a Scientific Poster

- Each group will create a scientific poster with a hyperlinked video showcasing the prototype that will be used to present to the class, or it can be used for an internal design competition, or it can be submitted for an external design competition. Have students refer to the How to Create a Scientific Poster/Video Instructional Worksheet and the Grade Sheet.

- Google Slides is very good – all group members can be working on a different part of the poster at the same time if the slide is shared with all group members. Teachers can also track student work on the poster, so we can see who did more work and who did less work.

- Note – A scientific poster should communicate the project using tables, graphs, images, and few words. Students will want to write paragraph after paragraph but that is not needed. Encourage fewer word and more images with captions. Using a video is better to explain how the device works.

Vocabulary/Definitions

bone callus: A bone and cartilage “patch” that forms across a bone fracture during repair.

fracture: Any break or crack in a bone.

fracture hematoma: A blood clot that forms 24-48 hours after a break in bone from the vessels that were torn during injury.

matrix: Substances in between cells in bone; the matrix is protein, sugar, fibers and calcium.

osteoblast: Cell that synthesizes a bone matrix.

osteoclast: Cell that breaks down a bone matrix.

osteocyte: Cell that maintains a bone matrix.

osteoprogenitor: A type of bone stem cell.

vascular: The quality of possessing blood vessels.

Assessment

Pre-Activity Assessment

Recipe for a bone (deconstruction of a bone): Using the Recipe of a Bone/Deconstruct a Bone Pre-Assessment, ask students to break down the largest bone in the body – a femur. If you have access to a model femur, pass it around the room and have students think about what makes up bone.

Some guiding questions:

- Why is bone solid? (Calcium)

- What cells are in bone? (4 types – osteoprogenitor, osteoblast, osteocyte and osteoclast)

- What lies in between the cells? (Matrix – sugar, protein and fiber)

- What brings nutrients to the cells? (Blood and blood vessels)

Activity Embedded (Formative) Assessment

Initial Prototype Idea, Individual:

Provide everyone with the Initial Prototype Idea Individual Worksheet. This assessment is completed after group sessions to hold each group member responsible for one new design idea and it will let the teacher know if each student in the class is understanding the overall task of Engineering a Better Cast.

Constantly visit groups as they work, ask to see the white boards with notes to keep the group moving forward and to ensure that all group members are working.

Post-Activity (Summative) Assessment

Scientific Poster and Video:

Scientists use posters to share research with the community. A scientific poster is challenging for students because it relies on images, graphs, and tables to explain the Engineering a Better Cast project and design instead of paragraphs of text to explain a process or project. Instructions and grading are found below.

Investigating Questions

What do we need to consider when selecting materials that will be used in or on the body?

- Safety is the main issue – we want to help heal the broken bone and not cause injury to muscles or skin.

- Cost is another issue – if the materials selected are too expensive, the device will never be approved.

What tests can be used to determine if my prototype meets specifications? If my prototype fails a test, how can I redesign?

Troubleshooting Tips

- Students might struggle with the creativity required in design simply because they are not often asked to do this in a classroom. The Sketching Worksheet is a struggle at first because students need to expand on another person’s idea without talking.

- They will excel when prototyping but be careful that 1-2 students do not take over the build, every student should be included in that process.

- Consistent monitoring of groups during the prototyping and testing days is important to ensure that all students are contributing, and that testing makes sense. Iteration is encouraged throughout this process so repeat how important it is to test and re-design.

- All students should contribute to the poster creation and to the video showcasing the prototype.

- See Example of a student-generated poster and Prototype examples for guidance and ideas on poster creation and student-generated prototypes.

Activity Extensions

Submit prototypes and posters to local orthopedic surgeons for feedback and questions. Redesign based on this feedback and create an internal design competition. Ask students to generate a list of medical “complaints” that can be turned into additional design challenges—can we redesign needles used for injections? Design eyeglasses that don’t fall off of the nose.

Activity Scaling

Assign group members based on student strengths—one who is the organizer, another who is good with computers, someone is comfortable with using tools to build.

Consider asking advanced students to incorporate technology like a computer interface or nanotechnology in the design.

Incorporate computer-aided drafting (CAD) and require 3D printing of small components to be used in building the prototype with the help of a tech ed class. Require a cost-analysis and marketing analysis with the help of a business class.

For lower grades, limit the types of materials to be used in the prototype. Create kits of materials to use.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn how forces affect the human skeletal system through fractures and why certain bones are more likely to break than others depending on their design and use in the body. They learn how engineers and doctors collaborate to design effective treatments with consideration for the location, ...

Students learn about the strength of bones and methods of helping to mend fractured bones. Working as biomedical engineers, student teams design their own splint or cast to help repair a fractured bone, learning about the strength of materials used.

References

Buchenau, Marion, “Experience Prototyping” (2000), Proceedings of the Conference on Designing Interactive Systems, IDEO San Francisco, DOI:10.1145/347642.347802

Marieb, Elaine, Fundamentals of Anatomy & Physiology, 11th edition, Pearson 2019.

Copyright

© 2022 by Regents of the University of Colorado; original © 2019 University of PittsburghContributors

Shari Morasco, MEd, teacher, Gateway Senior High School; Mahender Mandala, PhD, Computer Interaction Department, Georgia Tech; Mary Goldberg, PhD, Associate Professor, Department of Rehabilitation Science & Technology, University of PittsburghSupporting Program

Research Experience for Teachers (RET), Human Engineering Research Labs, University of PittsburghAcknowledgements

This curriculum as developed under the National Science Foundation Research Experience for Teachers on Quality of Life Technology Award at the University of Pittsburgh, grant no.1609566. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: June 8, 2022

User Comments & Tips