Summary

Following the steps of the iterative engineering design process, student teams use what they learned in the previous lessons and activity in this unit to research and choose materials for their model heart valves and test those materials to compare their properties to known properties of real heart valve tissues. Once testing is complete, they choose final materials and design and construct prototype valve models, then test them and evaluate their data. Based on their evaluations, students consider how they might redesign their models for improvement and then change some aspect of their models and retest—aiming to design optimal heart valve models as solutions to the unit's overarching design challenge. They conclude by presenting for client review, in both verbal and written portfolio/report formats, summaries and descriptions of their final products with supporting data.Engineering Connection

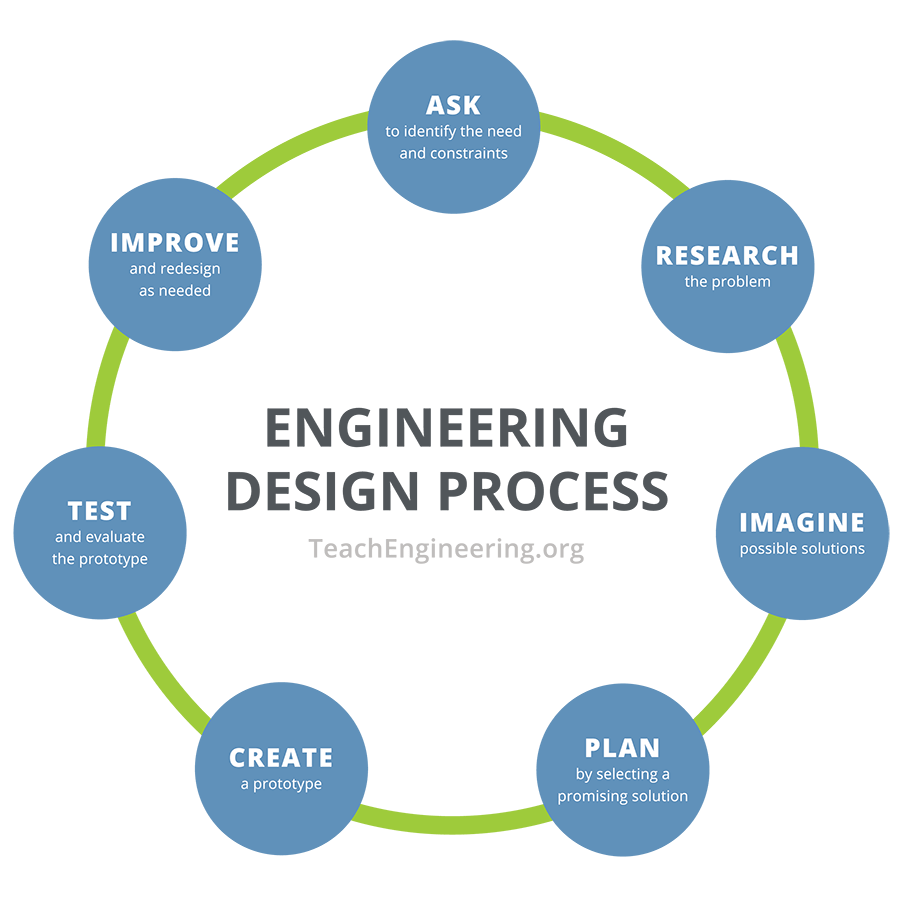

When engineers are presented with challenges to develop new technologies or products, they follow the steps of the cyclical engineering design process. After learning as much about a project as possible, they choose the best materials, and proceed to prototype and test the best design solution. Biomedical engineers research to find (and sometimes create new) materials that are suitable to fabricate artificial replacement heart valves. The ideal materials have similar properties and behavior to real heart valve tissues. They use these materials to develop valve designs that mimic the function of real valves.

During this activity, like biomedical engineers, students research and test potential materials that mimic the qualities of heart valve tissue. They collect quantitative evidence to determine if any of the materials are appropriate for artificial valve designs. Then they choose the best materials to design, construct, test, improve and present final aortic valve models for client review.

Learning Objectives

After this activity, students should be able to:

- Work through the steps of the engineering design process to examine a problem, research it and decide the best way to tackle it, design and create a solution, test the prototype solution and redesign as needed, and then report their findings.

- Research the materials that have been used in artificial heart valves in the past; identify possible materials for their prototype valve model designs.

- Test materials to determine their elasticities; compare those values to the elasticity of real heart valves.

- Construct prototype model heart valves, collect data from testing the model for its functionality compared to a real structure, and use the data to analyze success of the model.

- Compile, summarize and present their research and designs to the class in verbal and written formats.

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-LS1-2. Develop and use a model to illustrate the hierarchical organization of interacting systems that provide specific functions within multicellular organisms. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop and use a model based on evidence to illustrate the relationships between systems or between components of a system. Alignment agreement: | Multicellular organisms have a hierarchical structural organization, in which any one system is made up of numerous parts and is itself a component of the next level. Alignment agreement: | Models (e.g., physical, mathematical, computer models) can be used to simulate systems and interactions—including energy, matter, and information flows—within and between systems at different scales. Alignment agreement: |

Common Core State Standards - Math

-

Model with mathematics.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Graph functions expressed symbolically and show key features of the graph, by hand in simple cases and using technology for more complicated cases.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Interpret the slope (rate of change) and the intercept (constant term) of a linear model in the context of the data.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data on two quantitative variables on a scatter plot, and describe how the variables are related.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Summarize, represent, and interpret data on two categorical and quantitative variables

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Fit a linear function for a scatter plot that suggests a linear association.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Solve equations and inequalities in one variable

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the relationships among technologies and the connections between technology and other fields of study.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Medical technologies include prevention and rehabilitation, vaccines and pharmaceuticals, medical and surgical procedures, genetic engineering, and the systems within which health is protected and maintained.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Design problems are seldom presented in a clearly defined form.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Technological problems must be researched before they can be solved.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Tennessee - Math

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Model with mathematics.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Summarize, represent, and interpret data on two categorical and quantitative variables

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data on two quantitative variables on a scatter plot, and describe how the variables are related.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Fit a linear function for a scatter plot that suggests a linear association.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Interpret the slope (rate of change) and the intercept (constant term) of a linear model in the context of the data.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Graph functions expressed symbolically and show key features of the graph, by hand in simple cases and using technology for more complicated cases.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Solve equations and inequalities in one variable

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Tennessee - Science

-

Explore the anatomy of the heart and describe the pathway of blood through this organ.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Describe the biochemical and physiological nature of heart function.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Differentiate among elements of the engineering design cycle: design constraints, model building, testing, evaluating, modifying, and retesting.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Explain the relationship between the properties of a material and the use of the material in the application of a technology.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Graph relationships and functions between manipulated (independent) variables and responding (dependent) variables.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Determine the slope of a linear function.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- computer or tablet for Internet research and data graphing; Microsoft Excel® or similar software is recommended so students can graph data and determine lines of best fit; if graphing software is not available, have students use graph paper and plot by hand, although a less-accurate method

- ring stand

- Engineering Design Handout

- (optional) Rubric for Aortic Valve Model Portfolio/Presentation

To share with the entire class:

- hanging mass sets

- hooks for hanging materials from the ring stands

- precise calipers and rulers, to measure very thin materials

- a variety of materials from which groups can make models, such as balloons, paper, plastic, rubber, latex gloves, hose/tubing, clear plastic sheets, laminated cardboard or other household, recycled or found materials

- a variety of materials and tools that students can use to fabricate models, such as tape, glue, scissors, paper clips, hot glue guns

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/van_floppy_lesson02_activity1] to print or download.Pre-Req Knowledge

Students should be familiar with:

- The structure of the heart and its function, as explored in the What Do I Need to Know about Heart Valves? lesson and The Mighty Heart activity.

- The math concepts of stress, strain and elasticity, as presented in the Elasticity & Young's Modulus for Tissue Analysis lesson.

- Graphing data with Microsoft Excel® (or similar software application) to make line graphs or scatter plots and determining lines of best fit and their equations.

- Given an equation of a line, identify the slope.

Introduction/Motivation

Remind students of the challenge question that was introduced in the first lesson of this unit:

You are the lead engineer for a biomaterials company that has a cardiovascular systems client who wants you to develop a model that can be used to test the properties of heart valves without using real specimens. How might you go about accomplishing this task? What information do you need to create an accurate model? How could your materials be tested?

Now that you have learned some background information about blood flow, heart structure and valve structure, it is time to start designing your replacement heart valve models. To accomplish this, you will be permitted to use any materials that you wish to create your models. Ideally, the materials should not cost much money, and could be collected from home. Types of material that you might consider using include latex or plastic from balloons and gloves, rubber pieces, tape, plastic, laminated cardboard, or any number of other household and found materials.

First, choose materials that you think you want to use and test them to determine the most suitable ones. When creating tissue that will act as an analogue for real heart valve tissue, make sure to consider the physical properties of the material. You want the material to act similarly to real heart valve tissue. As you do this part, remember the structure of aortic valves and what each layer of the valve does. Your model should mirror those properties as closely as possible. It may be helpful to compare the physical properties of your potential model to the physical properties of heart valves. We will discuss some of these properties and you can find out about others through online research.

Once you have selected materials, begin the design and fabrication of your prototype replacement heart valves, which will also need to be tested. Since your artificial valve material will be used in the place of real heart valve tissue, aim to make your model as similar to organic valve tissue as possible. Consider the design of the real valve when you are choosing and testing your artificial valve tissue.

Procedure

Background Information

Now that students have learned about how heart valves are structured and work, they tackle the unit's challenge question. Working in groups, students develop a material that mimics the action of a heart valve so that it can be used for testing instead of real heart valves. To do this, they choose materials that best perform this function, design and create prototype valves, then test and refine them to end up with the best possible products. Once this is achieved, they present their findings and prototype models to the company's potential buyer in verbal and written formats.

At the core of the activity—material selection—students need to consider the trilaminar structure of aortic valves, and choose a number of materials that might be similar to the different layers of the valve. In particular, they should choose materials that possess similar properties to the ventricularis and the fibrosa layers.

Once materials are identified, teams test their materials to gather information on their elasticities, which informs the material selection process. Then teams use the selected materials to begin construction of the model prototypes. They may need to experiment with several different model ideas before designing one that meets the specifications:

- The model is thin like an aortic valve.

- The model is made of at least two layers.

- One of these layers is more elastic than the other.

- The model recoils back to the "open position" after force is removed from it.

Once teams' models are built, tested and redesigned (as needed and as time permits), then they compile portfolios to present to the company's client. This involves gathering together all the information they collected on the model, including research on tissue properties and behavior, design sketches and photographs, and material testing results. Assess the quality and completeness of the portfolios—the final product of the unit—by using the attached rubric. Consider distributing the rubric to groups at the beginning of the assignment, so they know how their work will be assessed.

Refer to the two lessons in the unit for more background information on forces, elasticity, stress, strain, valve structure, valve tissue properties and Young's modulus.

Activity Schedule

Day 1:

- Students begin researching suitable materials for their prototype valve models.

- Students test materials, collect data and calculate Young's modulus values to find materials that best represent real heart valve tissue.

Day 2:

- Wrap up any testing and decision-making not completed on Day 1.

- Construction, testing, evaluation and redesign of prototype heart valve models.

Day 3:

- Perform data analysis for the heart valve models. Redesign and retest as necessary.

- Work on presentation portfolio for the "client."

- Use provided rubric to assess students' final portfolios.

Before the Activity

- Gather materials and make copies of the Engineering Design Handout and Rubric for Aortic Valve Model Portfolio/Presentation, one each per group.

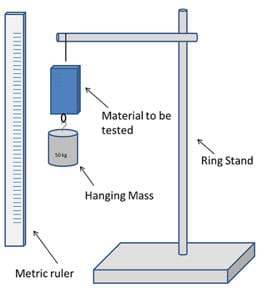

- Set up an elasticity-testing station(s) (see an example in Figure 1), or provide some basic supplies but let teams set up their own testing setups.

- Make available computers with graphing software; alternatively, provide graph paper for students to plot by hand.

- Have assorted materials and supplies set up and available for students.

With the Students

- Referring to the handout, review the engineering design process with the class, pointing out that they already have a defined problem and have already done a good deal of research towards finding a solution. Explain the steps that are coming up in this activity as they work in groups to devise a solution to the unit's engineering design challenge: identify and evaluate possible design strategies, which includes identifying possible tissue-like materials, test and evaluate possible materials, create the prototype model using the best material(s), test the model, revise to improve the model, test again—and repeat until a satisfactory solution is achieved—and then communicate a description of the finished model and its data for presentation to the company's client.

The steps of the engineering design process. - Divide the class into groups of three students each. Direct student groups to choose materials that are available to them, either in class or from home, that they may be interested in using to create their model heart valves.

- Direct students to test their identified materials to determine the elastic modulus. Testing can be accomplished by using any elevated structure (such as a ring or wire stand) to hang the material, and then attaching mass to the end of the material (see an example in Figure 1). Then compare the initial length of the hanging material to its length when different masses are added by calculating the change in length of the material for each mass added. The data collected is used to determine the Young's modulus of each candidate material.

Figure 1. An example setup to gather data to determine the elasticity of a material. - Direct students to determine the Young's modulus of each material, applying what they learned from the associated lesson. Have students use software to create stress vs. strain graphs and determine lines of best fit; as an alternative, have students use graph paper and do this by hand. For each material, have teams:

- create a stress vs. strain graph, plotting at least three data points determined by using at least three weights of different masses to measure and calculate stress and strain

- determine the line of best fit based on the three points on the graph

- determine the slope of the best fit line, which is the experimentally determined Young's modulus

- Remind students:

- Stress is equal to force divided by area (F/A), where force is equal to the weight of the mass and area is equal to the cross-sectional area of the material being tested.

- Strain is equal to the change in length of the material divided by the initial length of the materials (ΔL/L0).

- As necessary, use precise rulers or calipers to measure very thin materials.

- Have each group compare its calculated values to the Young's modulus of heart valves (or even the different layers of heart valves) as part of choosing materials that would be best for the model. For reference, the Young's modulus value for a pig's heart valve tissue and some other materials are provided below; encourage students to conduct research to find values for human heart valves or even the layers of the heart valves. (Tip: This research may be very challenging for students; see the Troubleshooting Tips section for some values and suggested research links.)

- Pig heart valve: 1.2 X 106 Pascal (Pa)

- Rubber: 1.0 X 108 Pa

- Tooth enamel: 8.3 X 109 Pa

- Steel: 2.0 X 1011 Pa

- Carbon nanotube: 1.0 X 1012 Pa

- Once groups have selected their materials, direct them to design and construct their models.

- Direct teams to test their models similarly to how individual materials were tested (as described in steps 3 and 4), in addition to being tested qualitatively. To do this, students might hold the model stationary, pull it down some, and see if it recoils back to its "open" position. Doing this mimics the action of a real heart valve functioning in a live body. Remind students that testing models and ideas is a vital aspect of the engineer design process. With this project, the intent is to test their models to see how they act under conditions similar to those in the body. For engineers, designing creative testing procedures is often part of the process.

- Based on the data that students obtain through testing, they may want to go into step 7 of the engineering design process and redesign their models and retest, as needed. Engineers usually revisit their proposed solutions many times to make sure they are the best solutions to the problems. For redesigns, students might opt to choose different materials, look into ways to combine the materials differently, or alter the sizes of their model/materials—just as engineers would do. The cyclical improvement process that students experience is a good example of the iterative nature of the engineering design process.

- Once group models are completed to satisfaction (or time limit), direct each group to compile all of its materials into a portfolio that summarizes and showcases the pertinent background information learned, materials chosen, model design, prototype photographs, material and model testing data, and an analysis of the model with recommendations for model use.

- To conclude, have groups each present their portfolios to the class, as if they were making a professional engineering presentation to a client. Communicating the data, explanations and descriptions of completed design projects is an important part of engineering. Use the rubric to evaluate each team's success in terms of achieving a viable solution, presenting its logic and model design, and compiling its written report "portfolio."

Vocabulary/Definitions

elasticity: A material property in which it returns to its original shape after stress has been applied and removed.

engineering design process: A series of steps followed by engineering teams to research, design, build, test and redesign to create a solution to a problem. The process is noted for its cyclical and iterative process, by which initial designs are revisited and improved until a satisfactory design is achieved.

model: A representation of something for imitation, comparison or analysis, sometimes on a different scale.

portfolio: A collection of work that outlines the steps taken and end product of a project. May be presented in a physical (collection of pages or posters) or electronic form.

prototype: A first attempt or early model of a new product or creation. May be revised many times.

Young's modulus: A measure of the stiffness of a material; a ratio of the stress applied to the material to the strain (deformation) of the material. Every material has a specific modulus.

Assessment

Pre-Activity Assessment

Review: To refresh students' memories regarding heart anatomy and the movement of blood through the heart, conduct a quick pre-test by asking students the following questions as an entire class or individual written quiz.

- What path does blood take through the heart?

- What is the role of heart valves in the flow of blood through the heart?

- What types of properties might a heart valve require in order to perform this function?

Activity Embedded Assessment

Questioning, Guidance and Observations: During the activity, walk among the engineering teams, helping them make progress through the engineering design process. Question students about their ideas to test the materials they have identified, and ask how they plan to test their models. Also ask students why they need to be aware of the Young's modulus values for real heart valve tissue. These informal queries reveal whether students need further resources or guidance on how to proceed.

Post-Activity Assessment

Data Analysis Explanation: At activity end, have each group present to the class and instructor its collected data and an explanation of how they collected it. Expect students to describe what these data indicate when compared to the modulus data for real valve tissues. Expect this analysis and understanding to be included in the written portfolio.

Portfolio: Assign groups to each create a portfolio that collects and summarizes pertinent design notes, diagrams, material test data, redesign notes, sketches, pictures and specifications of the prototype heart valve model "product" for the company's client. Use the Rubric for Aortic Valve Model Portfolio/Presentation to assess students' portfolios and presentations.

Making Sense: Have students reflect about the science phenomena they explored and/or the science and engineering skills they used by completing the Making Sense Assessment.

Safety Issues

While safety is not a big concern for this activity, guide students to follow general lab safety protocols.

Troubleshooting Tips

Students may struggle with this activity because it is different from the more commonly experienced science labs in which students follow a set protocol to generate a series of data that is likely expected by the teacher (if not also students). Even in open-ended labs, students are rarely asked to evaluate the data from their first tries and redesign their protocols to get better results. In this activity, the instructor asks students to use their own research to identify materials to use in their models, test them, make decisions based on their results, design and construct prototype models, and test them. Once they test their models, they will likely need to redesign them and test further to ensure they are the best possible solutions to meet the challenge. Encourage students, without giving them answers, since part of the strength of activities that employ the engineering design process lies in the fact that students are thinking critically to design, evaluate and redesign their solutions.

Measuring of the cross-sectional area for many materials can be very challenging because most are very thin; have students use precise rulers or calipers to measure one dimension.

Expect students to have some difficulty finding online data on the Young's modulus of human heart valve tissues. Help them out with the following suggestions:

- Development of a completely biological tissue engineered heart valve by Zeeshan Hayder Syedain, University of Minnesota, US. This PhD dissertation cites Young's modulus, also known as modulus of elasticity or elastic modulus, values for the fibrosa layer of the aortic valve as 23 MPa in the circumferential direction and 3.71 MPa in the radial direction and for the ventricularis layer as 9.55 MPa in the circumferential direction and 3.7 MPa in the radial direction: https://search.proquest.com/openview/44a2e388938cfa177ecd101eb4e83f47/1?pq-origsite=gscholar&cbl=18750&diss=y

- The collagen organization in heart valves: a target for tissue engineered valves by A. Balguid et al., Eindhoven University of Technology, Netherlands. This poster summary of a paper provides an average Young's modulus value of approximately 20.9 MPa for human heart valves in the circumferential direction and approximately 2.1 MPa in the radial direction): https://pure.tue.nl/ws/portalfiles/portal/3611010/573478956992773.pdf

- A new approach to heart valve tissue engineering based on the modification of human pericardial tissue by Frantisek Straka et al., Institute of Physiology, Czech Republic. The abstract of this paper states that elastic modulus of approximately 13.1 MPa is comparable to native aortic heart valve: http://www.qscience.com/doi/abs/10.5339/qproc.2012.heartvalve.4.79

- St. Jude Epic heart valve bioprostheses versus native human and porcine aortic valves – comparison of mechanical properties by Martins Kalejs et al., Pauls Stradins Clinical University Hospital, Latvia. This abstract provides Young's modulus, also known as modulus of elasticity, for aortic valves from humans and pigs: https://www.researchgate.net/publication/23974299_St_Jude_Epic_heart_valve_bioprostheses_versus_native_human_and_porcine_aortic_valves_-_Comparison_of_mechanical_properties

- Mechanical properties of chordae tendineae of the mitral heart valve: young's modulus, structural stiffness, and effects of aging by Laura Millard et al., University of Birmingham, UK. The abstract of this paper provides Young's modulus values for the chordae tendineae of the mitral valve in pigs: https://www.worldscientific.com/doi/abs/10.1142/S0219519411003971?journalCode=jmmb

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn how healthy human heart valves function and the different diseases that can affect heart valves. They also learn about devices and procedures that biomedical engineers have designed to help people with damaged or diseased heart valves.

Students are presented with the unit's grand challenge problem: You are the lead engineer for a biomaterials company that has a cardiovascular systems client who wants you to develop a model that can be used to test the properties of heart valves without using real specimens.

As part of the engineering design process to create testable model heart valves, students learn about the forces at play in the human body to open and close aortic valves. They learn about blood flow forces, elasticity, stress, strain, valve structure and tissue properties, and Young's modulus, incl...

Students use their knowledge about how healthy heart valves function to design, construct and implant prototype replacement mitral valves for hypothetical patients' hearts. Building on what they learned in the associated lesson about artificial heart valves, combined with the testing and scoring of ...

References

Campbell, N., Reece, J., Urry, L., Cain, M., and Wasserman, S. Biology. Eighth edition. San Francisco, CA: Benjamin-Cummings Publishing Co., 2007.

Nagatomi, Jiro. Mechanobiology Handbook. Boca Raton, FL: CRC Press, 2011.

Copyright

© 2013 by Regents of the University of Colorado; original © 2012 Vanderbilt UniversityContributors

Michael DuplessisSupporting Program

VU Bioengineering RET Program, School of Engineering, Vanderbilt UniversityAcknowledgements

The contents of this digital library curriculum were developed under National Science Foundation RET grant nos. 0338092 and 0742871. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: March 20, 2023

User Comments & Tips