Quick Look

Grade Level: 8 (6-8)

Time Required: 45 minutes

Lesson Dependency:

Subject Areas: Earth and Space, Science and Technology

NGSS Performance Expectations:

| MS-ETS1-1 |

Summary

Have you ever wondered why it takes such a long period of time for NASA to build space exploration equipment? What is involved in manufacturing and building a rover for the Red Planet? During this lesson, students discover the journey that a Mars rover embarks upon after being designed by engineers and before being prepared for launch. Students investigate the fabrication techniques, tolerance concepts, assembly and field-testing associated with a Mars exploratory rover to prepare for the associated activities where they design their own rover prototype.Engineering Connection

When designing a Mars rover — or any engineered object (cars, appliances, medical equipment, computers, telephones, televisions, toys, etc.) — engineers determine what parts to make and how tight the pieces should fit together. They decide which fabrication methods to use and which manufacturers to fabricate and assemble the parts. Since different manufacturers may be making different parts, engineers make sure that all of the parts fit together precisely by specifying for the fabricators acceptable tolerances, or numerical ranges.

Learning Objectives

After this lesson, students should be able to:

- Describe the role of engineers in designing Mars rovers.

- Articulate the basic steps that a rover undergoes after being designed and before launch.

- Provide examples of the fabrication methods used to manufacture parts for Mars rovers.

- Explain the concept of a tolerance and why it is essential for NASA to utilize tolerances.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This lesson focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

Common Core State Standards - Math

-

Find and position integers and other rational numbers on a horizontal or vertical number line diagram; find and position pairs of integers and other rational numbers on a coordinate plane.

(Grade

6)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Manufacturing systems use mechanical processes that change the form of materials through the processes of separating, forming, combining, and conditioning them.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Colorado - Science

-

Describe methods and equipment used to explore the solar system and beyond

(Grade

8)

More Details

Do you agree with this alignment?

Pre-Req Knowledge

Basic knowledge about Mars rovers, which is covered in the Red Rover Robotics lesson of the Mission to Mars unit.

Introduction/Motivation

What do we call the vehicles that are used to explore Mars? (Listen to student suggestions. Answer: Rovers or Mars rovers.) Teams of engineers and scientists at NASA design the rovers that are used to explore the Red Planet.

With a partner, brainstorm what steps are required to produce a Mars rover after the rover is designed and before it is launched. (After students have had time to brainstorm, ask groups to share how they think the rovers are fabricated. After hearing from several groups, write on the board the actual steps - advanced manufacturing, fabrication, assembly and field testing - that it takes to build a rover after is has been designed by engineers.) To fabricate or to manufacture both mean to make something.

Advanced manufacturing engineers determine which rover parts to make (or fabricate) at NASA and which parts to have outside companies make. Some of the special machines used to fabricate parts for the rover are: a vertical milling machine, a computer numerically controlled (CNC) machining center, and a lathe. Also, the people who operate these machines and fabricate the metal parts are called machinists.

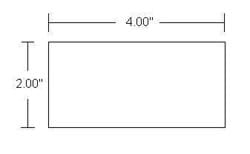

(Draw a three-dimensional cube or block on the board.) How would a machinist know what size to make this block? Would they guess? (Possible answers: Yes, they could guess, but even better, you tell them the exact size you need the block to be.) Engineers are able to tell machinists specific sizes that they need by using dimensions — by labeling the measurements for each side, angle, opening, etc. (Add a dimension on the block drawn on the board, for example, each side is 3 cm or 3 m).

(If available, use two Mega Bloks™ or large LEGOs™ to show students that even toys are fabricated by machinists.) Look at these toy blocks. How is it that they always fit together perfectly? (Answer: The perfect fit comes from tolerances, which are numbers used to describe how accurate something must be.) What do tolerances have to do with a Mars rover? Why would engineers want to be accurate with the rover? (Listen to student suggestions. Answer: Precision is very important in engineering. If a rover is not made with tolerances [accuracy], its function might be compromised, and it could fail while it is far away in space, which would result in tremendous loss of effort, time and money.)

During today's lesson, you will learn how Mars rovers are manufactured. Then, students will have the opportunity to design their own rovers with the hands-on design activities: Edible Rovers and Edible Rovers - High School where students use edible materials to satisfy certain tolerance and cost constraints.

Lesson Background and Concepts for Teachers

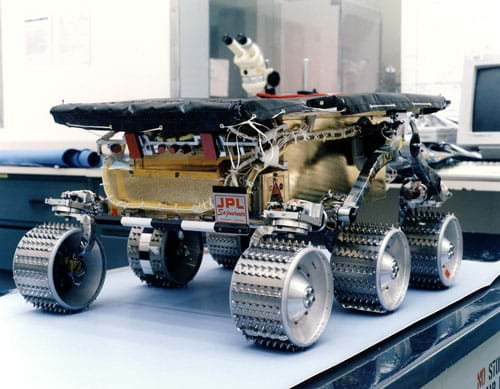

The Sojourner, Spirit and Opportunity Mars exploratory rovers were assembled (put together) and came "alive" at NASA's Jet Propulsion Laboratory (JPL) in Pasadena, California. The following sections describe the basic steps that are necessary to prepare rovers for the exploration of Mars, the Red Planet.

Advanced Manufacturing

After scientists and engineers finish the design of a rover, the plans are sent to the Advanced Manufacturing group at NASA, whose responsibility is to review the design plans and decide what can be made on-site and what should be outsourced (sent outside of NASA) to local manufacturers. Typically, standard parts are sent out to various machine shops for fabrication. When Spirit and Opportunity were built, approximately 80% of the parts were made outside of JPL. However, the rover parts that had a complex geometry were made at the high-precision fabrication shop in JPL. By keeping the complex parts in-house, the designers could closely communicate with the person making the parts and make design changes when needed.

As expressed by Mike Mangano, a project element manager with NASA's Mars Exploration division, "You can do the design, you can put it on paper, but until you start to actually make it, you don't know what kinds of problems you're going to run into."

Fabrication

The people who work in fabrication shops and make the metal parts are called machinists. When making parts for a rover, it is essential that a machinist manufactures or fabricates parts that exactly match the engineer's size specifications. An engineer is able to communicate the exact part size that they desire by creating a drawing of that part and placing dimensions (sizes) on the drawing. A dimension, therefore, is a measurement between two points. A basic block with dimensions is shown in Figure 3. The size of a rover's parts is critical because all the parts must fit together precisely. Accurate parts help the rover stay alive on its long journey to Mars and when landing on the planet. Figure 4 shows these parts coming together at NASA's Jet Propulsion Laboratory.

Some of the machines used to make rover parts at JPL's high-precision fabrication shop — and at fabrication shops outside of JPL — include milling machines, lathes and CNC (computer numerically controlled) machining centers. A milling machine is a very versatile piece of equipment. A vertical milling machine uses rotary cutters that are vertically mounted to remove material from a basic shaped work piece (such as a cube or a cylinder). The machine's table can move up/down, right/left and forward/backward.

Fun Fact: One machinist at JPL compared the assembled rover to a Russian nesting doll, a Matryoshka doll. Like a Matryoshka doll all of the rover's pieces fit together in a minute space. This creative assembly allows NASA to build and launch rather small spacecraft systems.

CNC machining centers (see Figure 5) are automated machines that allow machinists to quickly and accurately create parts with complex surfaces. The machining center can perform operations such as milling, drilling, boring and tapping. However, for parts to be created on a CNC machining center, the machine's computer must first be programmed. During the design phase of a project, engineers use computer-aided design (CAD) software to create an exact picture of their model and its parts. A CAD program allows engineers to draw parts on a computer in 2-D or 3-D and then analyze the design and how parts fit together for assembly. Once a part has been drawn in CAD, a conversion program is used to convert the part's shape from CAD to fabrication instructions that the CNC machining center can understand. The CNC machining center automatically changes its tools to what is needed and then creates the part by removing material from a basic shape (for example, starting from a cube of aluminum).

A lathe (see Figure 6) is typically used to fabricate parts that are cylindrical in shape. Metal (or plastic) is held in a lathe horizontally, and material is removed to manufacture a desired shape. During operation, the cylindrical material is held in a chuck, or collet, and then rotated while a cutting tool travels left and right or forward and backward to remove material.

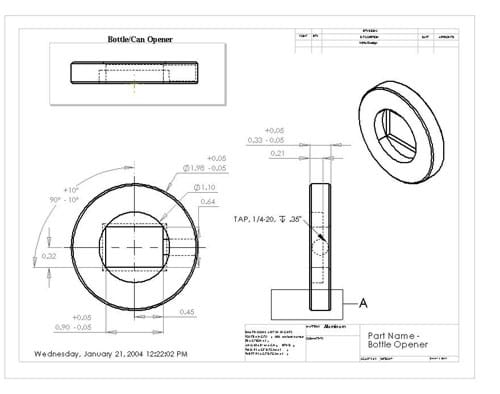

Tolerances

A tolerance is a numeric range used to specify accuracy levels. Tolerances are typically specified on engineering drawings similar to Figure 7. Notice that the thickness dimension is 0.33" and the tolerance is +0.05" and –0.05". This means that the thickness of the bottle/can opener should have a maximum thickness of 0.38" and a minimum thickness of 0.28".

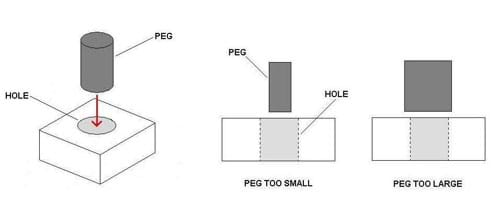

So why do engineers need to use tolerances? One of the best examples of a company that relies on tolerances is LEGO™. If the cylindrical nub on top of a LEGO is too big, then another LEGO piece will not fit on top of it. If the cylindrical nub is too small, then any LEGO piece that you place on the top will not stay positioned. A simple way to illustrate the need for tolerances is by showing a peg and block assembly (see Figure 8). If the peg is too large, it will not fit in the hole of the block. If the peg is too small, it will fall through the hole in the block and the two pieces will not fit together.

It is important that NASA and the aerospace industry maintain very tight tolerances on the parts that they manufacture to ensure spacecraft operation. As a result, NASA specifies that parts be fabricated within 0.001" (or 0.03 mm) of the specified dimension. These manufacturing specifications help to ensure that assembled space exploration equipment fits together properly and is robust enough to complete the intended mission.

Assembly

Each rover part must be correctly fastened together before the rover is ready for launch. Keeping the rover "alive" once it lands on Mars requires engineers to use extreme caution when putting each specific piece of the rover together. It would be terrible if the rover lost a wheel or robotic arm as it journeyed across relatively unknown Mars terrain! However, the rover pieces are like a complex 3-D puzzle. Fragile pieces of instrumentation are mixed in with lightweight metal parts, and each rover part has a correct place. If any piece is left out or put in the wrong place, the motors, controls, instruments or communication system may fail, leaving the rover stranded or non-functional on Mars.

Field Testing

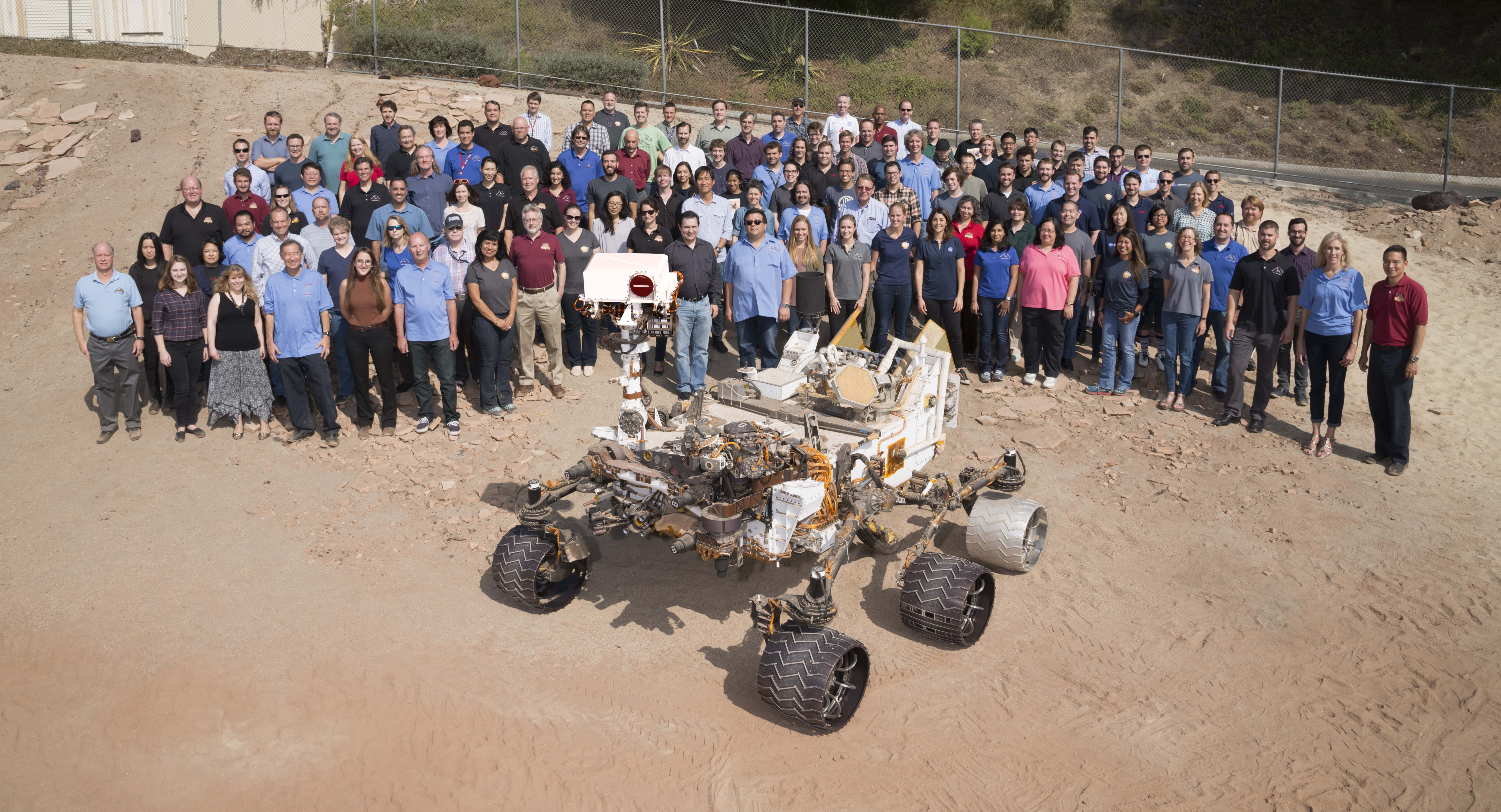

Before sending the exploratory rovers to Mars, NASA scientists and engineers prepare the rover and themselves for the intense operation by conducting field tests on Earth. The prototype rover utilized for these field tests in 2020 is shown in Figure 9.

The prototype rovers provide NASA the opportunity to practice the quick-paced exploratory mission that will be conducted by the rovers. During the field test, the mission team practices navigating the Mars terrain, and as a result, this trains the engineers to make prompt decisions as a team.

Once a rover lands on Mars, the mission team has a very short period of time to review incoming data. Scientists must quickly decide what they would like to investigate, while the engineers determine how the rover will reach each destination and if it is capable of reaching the desired research locations.

Watch as NASA engineer, Erisa Hines describes this process. https://www.youtube.com/watch?v=889k_hjUcbc

Associated Activities

- Edible Rovers - Students design and manufacture their own prototype Mars rovers using edible materials that fit specified tolerances.

- Edible Rovers – High School - Students act as Mars exploratory rover engineers, designing, building and displaying edible rovers to a design review. As part of the design, they evaluate equipment and material options in relation to a budget.

Lesson Closure

Ask two students to come to the board and write the four steps that a Mars rover experiences after it is designed and before it is launched. (Answer: Advanced manufacturing, fabrications/manufacturing, assembly and field test,) Remind students that machinists at the JPL precision fabrication shop use special machines to make the most complex parts for the Mars rovers and the more common parts are produced by outside companies. Ask students to name the three machines that are used to manufacture parts for the Mars rovers and write the answers on the board. (Answer: A vertical milling machine, lathe and CNC machining center.) Discuss why it is so important for NASA engineers and scientists to perform field tests. Explain that scientists and engineers must practice for their missions, just like students practice spelling words, lines for a play, sports or musical instruments.

Vocabulary/Definitions

assembly: The act of bringing together or fitting together parts.

CNC: A computer numerically controlled machining center. Used for manufacturing complex parts with high accuracy.

dimension: A measurement between two points on an engineering drawing.

fabrication: The process or making or manufacturing a product.

lathe: A machine used to make cylindrical shaped parts.

machinist: A person who works and manufactures parts in a fabrication or machine shop.

manufacturing: The transformation of raw materials into finished goods.

milling machine: A machine using rotary cutting tools to remove material from a basic shaped piece of material.

tolerances: A numeric range used to specify accuracy levels.

Assessment

Pre-Lesson Assessment

Brainstorming: In small groups, have students engage in open discussion. Remind students that in brainstorming, no idea or suggestion is "silly." All ideas should be respectfully heard. Encourage wild ideas and discourage criticism of any ideas. Ask the students to brainstorm the following question with a partner:

- What seps are required for a Mars rover after the rover is designed and before it is launched? Describe what each step entails.

Post-Introduction Assessment

Question/Answer: Ask the students and discuss as a class:

- Who is in charge of deciding what parts are made at NASA and what parts are made at other companies? (Answer: Advanced manufacturing engineers.)

- What is the title of the person who operates a vertical milling machine, a CNC machining center or a lathe to make metal parts? (Answer: A machinist.)

- How can you best describe to a machinist the size that you want a part to be made? (Answer: Use dimensions on a drawing.)

- What is another word you could use for fabricate? Answer: Manufacture.)

- What does CNC stand for? (Answer: Computer numerically controlled.)

Lesson Summary Assessment

Tolerating Tolerances: Divide the class into teams of two and have groups solve the following problems. Have teams discuss their answers with the entire class.

- If Part A has the dimension 0.50 inches and the tolerance is ±0.25 inches, what is the minimum and maximum size Part A can be? (Answer: 0.25 inches and 0.75 inches.)

- If Part B has the dimension 0.75 inches and the tolerance is ±0.1 inches, what is the minimum and maximum size Part B can be? (Answer: 0.65 inches and 0.85 inches.)

- Which part has a more precise tolerance? (Answer: Part B.)

- Have students create a horizontal line diagram to show the minimum and maximum sizes they determined in Parts A and B.

Flashcards: Have each student on a team create a flashcard with a question on one side and its answer on the other. If the team cannot agree on the answers, they consult the teacher. Pass the flashcards to the next team. Each member of the team reads a flashcard, and everyone attempts to answer it. If they are right, they can pass on the card to the next team. If they feel they have another correct answer, they write their answer on the back of the flashcard as an alternative. Once all teams have done all the flashcards, clarify any questions. Sample questions:

- Name the three machines used to manufacture parts for Mars rovers. (Answer: A vertical milling machine, lathe and CNC machining center.)

- Why is it important for NASA to have field tests? (Answer: So engineers and scientists can practice for their missions.)

Lesson Extension Activities

Internet Search: Have students investigate the prototypes of the Mars rovers that NASA engineers have used to perform field tests on Earth before the Mars. Start your research at:

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students are introduced to the planet Mars. They begin by discussing the location and size of Mars relative to Earth, as well many interesting facts about this "red planet." Next, the history of Martian exploration is reviewed and students discover why researchers are so interested in studying this ...

This lesson begins with a brief history of robotics, describing how robots are beneficial to engineering and society and then explores how robots have been used in recent space exploration efforts. The engineering design of the two Mars rovers, Spirit and Opportunity, are examples of advanced engine...

Students explore Mars and Jupiter, the fourth and fifth planets from the Sun. They learn some of the unique characteristics of these planets.

References

Assembly in Action: Image Sensors for Mars Rovers http://www.assemblymag.com/CDA/Archives/9a0961025e5c9010VgnVCM100000f932a8c0

NASA Names First Rover to Explore the Surface of Mars http://marsprogram.jpl.nasa.gov/MPF/rover/name.html

Machinist to the Stars http://marsprogram.jpl.nasa.gov/mer/spotlight/machinists01.html

Preparing for robotic exploration of Mars with a rover named FIDO http://marsprogram.jpl.nasa.gov/mer/fido/

Degarmo, Paul E., Black J.T., Kohser, R.A. Materials and Processes in Manufacturing. 9th Edition Update. Hoboken, New Jersey: Wiley Publishing Company, 2003.

Picture of lathe: http://www.mel.nist.gov/photos/photo/ph059.html

Copyright

© 2004 by Regents of the University of Colorado.Contributors

Daria Kotys-Schwartz; Geoffrey Hill; Chris Yakacki; Malinda Schaefer Zarske; Janet YowellSupporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under a grant from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education and National Science Foundation GK-12 grant no. 0338326. However, these contents do not necessarily represent the policies of the Department of Education or National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: August 8, 2020

User Comments & Tips