Quick Look

Grade Level: 9 (8-10)

Time Required: 2 hours

(can be split into two 60-minute sessions)

Expendable Cost/Group: US $2.00

Group Size: 4

Activity Dependency:

Subject Areas: Geometry

Summary

Students learn about the role engineers play in designing and building truss structures. Simulating a real-world civil engineering challenge, student teams are tasked to create strong and unique truss structures for a local bridge. They design to address project constraints, including the requirement to incorporate three different polygon shapes, and follow the steps of the engineering design process. They use hot glue and Popsicle sticks to create their small-size bridge prototypes. After compressive load tests, they evaluate their results and redesign for improvement. They collect, graph and analyze before/after measurements of interior angles to investigate shape deformation. A PowerPoint® presentation, design worksheet and data collection sheet are provided. This activity is the final step in a series on polygons and trusses.

Engineering Connection

To design strong, stable and safe bridges, engineers consider many factors. Foremost, they want their truss designs to adequately support the bridge and its expected load. They ask: Does it make sense to build? Is it strong? Is it safe? What will it look like? What does it cost? In this activity, students act as civil engineers following the steps of the engineering design process to design and create miniature truss bridges that they subject to compressive load testing—which presents an opportunity to experiment with their own creative compositions of geometrical shapes—just as real-world engineers do.

Learning Objectives

After this activity, students should be able to:

- Explain why a triangle is the strongest shape and integrate this knowledge into the design of a truss bridge structure that they subject to loading tests.

- Explain how the deformation of a shape affects the sum of its interior angles.

- Practice following the steps of the engineering design process when designing truss/bridge structures.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

-

Analyze complex real-world problems by specifying criteria and constraints for successful solutions.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

-

Models (e.g., physical, mathematical, computer models) can be used to simulate systems and interactions—including energy, matter, and information flows—within and between systems at different scales.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

Common Core State Standards - Math

-

Apply geometric methods to solve design problems (e.g., designing an object or structure to satisfy physical constraints or minimize cost; working with typographic grid systems based on ratios).

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Use geometric shapes, their measures, and their properties to describe objects (e.g., modeling a tree trunk or a human torso as a cylinder).

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Infrastructure is the underlying base or basic framework of a system.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

A prototype is a working model used to test a design concept by making actual observations and necessary adjustments.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Determine the best approach by evaluating the purpose of the design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Colorado - Math

-

Apply geometric methods to solve design problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Use geometric shapes, their measures, and their properties to describe objects.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- graph paper

- protractors

- ruler

- pencils

- scissors

- 100 Popsicle sticks

- hot glue gun and hot glue sticks

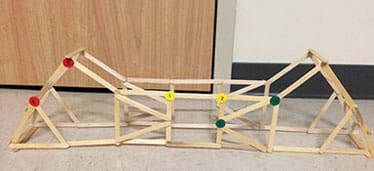

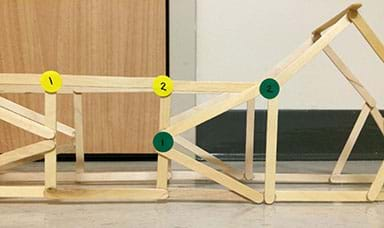

- 6 stickers, to tag target angles; see Figure 1

- Design a Truss Worksheet, one per student

- Data Collection Sheet, one per student

To share with the entire class:

- stacks of same-size textbooks, for compression testing

- capability to show the class the Introduction to Trusses Presentation, a PowerPoint® file

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_polygons_angles_trusses_lesson01_activity2] to print or download.Pre-Req Knowledge

Students should have an understanding of interior and exterior angles and be able to locate them inside and outside of triangles; refer to the associated lesson, Polygons, Angles and Trusses, Oh My!.

Introduction/Motivation

(Be ready to show the slide presentation, starting with slide 15)

(Slide 15) Have you ever walked across a simple footbridge made of boards or a rope bridge and noticed how the bridge changes shape (bends) as you walk across the center? It seems to change shape more over the center of the bridge than at the edges. This bending of the bridge is called deformation.

(Slide 16) Deformation refers to something that changes shape when pressure is applied. Engineers call the pressure—the force—that you apply when you walk on a footbridge a load. Have you ever noticed a bridge moving up and down as cars cross over it? The cars also create a load on the bridge that causes deformation. Engineers consider many factors in bridge design, including an estimate of the maximum load a bridge can support and how much deformation the bridge material can withstand before breaking.

Weight pushes straight down on a beam bridge, causing it to bend. A truss bridge is stronger than a beam bridge because the trusses create a framework that distributes the single point forces over a wider area. In terms of the bridge design, trusses may be positioned above or below the bridge deck (the road surface) and are designed in a variety of geometric patterns.

(Ask students the following questions and ask them to vote by thumbs up/down. Tally their votes on the board.) Which shape is more stable: triangles or squares? If an engineer designed a bridge truss only made of squares, would you feel safe standing on top of that bridge? What if the truss was composed of triangles? Under the same load, how would the deformation of the square be different that the deformation of the triangle? What makes up a strong structure? What types of shapes do you see in your everyday life that are sturdy and stable? These are all important considerations in truss design that you will be able to observe in the design and testing of your own bridge structures.

(Slide 17) Today, you are going to act as if you are engineers who are designing truss structures. Your engineering design challenge: Your engineering team has been tasked to create the strongest possible truss structure that will be used to design a bridge to cross one of our local rivers. Your objective is to design a truss that supports the weight of the vehicle traffic that will drive over the bridge. The truss must be sturdy and stable. You are also asked to make the truss design look abstract and unique; the clients do not want a truss structure simply made of plain triangles. Another design requirements is to use different regular polygons in your truss designs.

Procedure

Before the Activity

- Gather materials and make them available at a table for students to pick up later.

- Make copies of Design a Truss Worksheet and Data Collection Sheet.

- Review the procedure in full, including the testing process. Set up a test area in one part of the classroom with a supply of same sized books for incrementally adding load to the top of students’ trusses.

- Be ready to show the class the Introduction to Trusses Presentation, a PowerPoint® file, starting with slide 15.

With the Students

- Present to the class the Introduction/Motivation section contents, which includes showing slides 15-17, covering the topics of deformation, loads and strong shapes, and introducing the engineering design challenge. It also includes the pre-assessment voting questions. (10 minutes)

- Divide the class into teams of four students each. Have each group gather its supplies—graph paper, Popsicle sticks, stickers and hot glue—and organize a workspace.

- Hand out the worksheets and direct students to work in their groups and follow the worksheet procedures and instructions. In as much detail as you think necessary, go over the worksheet procedures and data collection (slides 18-22). Bring to students’ attention that during this entire project they will be following the engineering design process, which are the steps that engineering teams use to guide them as they develop new solutions, products, structures and systems. (5 minutes)

- Have students read over the worksheet and give them time to ask any clarifying questions. Then let the groups begin the process, guided by the procedure steps. Highlights are provided below with suggestions for supporting slides and teacher prompts.

- Groups select three different polygons to incorporate into their truss designs; one must be a triangle. The other options are: square, pentagon, hexagon, heptagon, octagon, nonagon and decagon (see slide 18). They make these shapes from Popsicle sticks as part of creating their truss designs (see slides 11, 19 and 22). Consider assigning each group a different more-complicated polygon.

- Observe teams as they brainstorm ideas and sketch truss designs on graph paper, making sure they use their three polygon shapes to form the truss designs. They are permitted to divide the polygons into smaller polygons. Mention that this is the idea-generating step of the engineering design process. Encourage them to come up with many ideas before choosing one for detailed planning, approval and construction.

- Keep students on task to document their truss plans on paper—taking no more than 20 minutes.

- As part of their planning, students find the sum of the angles in all of the shapes they used to create their trusses and record this on the data collection sheet (see slides 20-21 for the sum of interior angles equation). They also identify and measure two target angles for each polygon type.

- Review each group’s designs and target angle measurements; approve them by your initials on the worksheet so teams can continue.

- Teams begin construction of their prototype trusses. Mention that this is the “create: build a prototype” step of the engineering design process. Give students 30 minutes to construct their trusses from the wooden sticks and glue.

- Watch that teams identify and then mark with numbered stickers six target angles on their truss structures (see Figure 1 and slide 22). They use protractors to (accurately!) measure these angles and record them on the data collection sheet. Later, after the compressive load test, students will re-measure the target angles to determine the deformation (deflection) that occurred.

- Make sure that groups predict 1) how much weight (in number of books) they expect their trusses to hold, and 2) the expected deformation of their target angles. They record their predictions on their worksheets.

- Testing: Each team tests its prototype truss’ load capacity by applying one textbook at a time on top of the truss. During the test, the truss experiences a compressive load. Advise students to keep adding weight and observe until the failure of any truss component. Once the truss experiences deformation in the target angles, the team measures the angles of deflection and records the results. Remind students that they will have the opportunity to iterate, or redesign, their bridge prototypes after this first test.

- Students plot their team data on the data collection sheet. One graph shows the deflection in each angle vs. the number of sides in each polygon. The other graph shows the books the truss supported vs. the number of sides in each polygon. Have students fill out the second graph with class data as you collect (and call out to the class) data from each group: the largest sided polygon that they used to build their truss and the amount of books that it supported. Use the resulting graph to compare and contrast each group’s truss design and guide a discussion about the choice of polygons when designing trusses.

- Direct students to also plot the combined data from all teams by setting up large graphs on the classroom board for two class plots. Have someone from each team record its data on these graphs.

- Give teams the opportunity to redesign and alter their initial plans based on their results and what they learned from the first iteration. Expect them to be able to identify that triangles are the strongest shapes and be able to design second iteration trusses based on their own observations and results from the first iteration. Mention that iteration is an important part of the engineering design process, and that engineers use this process to develop real-world bridges that are stronger and safer than their initial designs. Suggest that teams discuss their improvement ideas and decide how to proceed.

- Give teams 15 minutes to iterate revised truss prototypes using their new ideas. After second trusses are built, let teams test again, applying books on top of the prototype structure until the truss experiences deformation in the target angles.

- After second-round testing, have students answer the worksheet reflection questions and turn in their worksheets.

- Conclude by leading a class discussion so students can share their results and reflections on the project, and examine the class data/graphs. See the Assessment section for some suggested prompt questions.

Vocabulary/Definitions

compression : A force that pushes inwards on a structural member.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products and systems. The basic steps include: ask: identify the need and constraints; research the problem; imagine: develop possible solutions; plan: select a promising solution; create: build a prototype; test and evaluate prototype; improve: redesign as needed.

prototype: A first attempt or early model of a new product or creation. Used to test a design concept by making observations and experimental adjustments. May be revised many times.

structural load: Forces that apply to a structure, such as the weight of something applied to the top, sides and/or floors of a structure.

tension : A force that pulls outwards on a structural member.

truss: A structural form made from the joining of individual structural members that form triangles or other stable, rigid shapes. Due to its geometric rigidity, a truss distributes weight from a single point over a wider area.

weight: The force exerted on a body by gravity.

Assessment

Pre-Activity Embedded Assessment

Voting: As part of the Introduction/Motivation presentation, ask students to vote by thumbs up/down on some questions about the strength of different shapes. Tally their votes on the board. Then, at activity end, ask the same question to see if responses change. Ask students: Which shape is more stable, triangles or squares? If an engineer designed a bridge truss only made of squares, would you feel safe standing on top of that bridge? What if the truss was composed of triangles? How would the deformation of the square be different that the deformation of the triangle—under the same load? What makes up a strong structure? What types of shapes do you see in your everyday life that are sturdy and stable?

Activity Embedded Assessment

Worksheet: Have students use the Design a Truss Worksheet to guide the activity. It provides the design challenge problem statement, objectives, materials list, requirements and constraints, and procedure. Review students’ answers to the reflection questions to gauge their depth of comprehension.

Prediction: Make sure teams remember to predict (on their worksheets) how much weight (in books) their trusses might hold, as well as expected deflection amounts (in degrees) for their target angles.

Post-Activity Assessment

Reflection Discussion: Lead a concluding class discussion so students can share their results and reflections about the project. For data/graph takeaways, include a discussion about different truss designs. For example, compare and contrast how many books each truss held, the size of the measured target angles, and how they played a role in the design outcomes. Highlight the amount of load it took to see a change in the angle and/or the focus on truss design itself and how target angle degree impacted truss collapse. Ask students: Did you succeed in creating a truss that held a compressive load? Approximately how much load did your truss hold? How many Popsicle sticks did you end up using? Do you think that engineers ever change their original plans during the prototyping and testing phases of the engineering design process? Why might they? Which polygons seemed to provide the best results/best support for truss structures? (Triangles usually provide the best results.) Why was this the outcome? If you had to do it all over again, how would your planned design change yet again? Why?

Voting: Revisit the pre-activity tallies on the board. Ask the same question to see if responses changed.

Activity Scaling

For higher grades, add a cost-constraint to the design process. Give each team $10 in fun money. In advance, make a supply of two Popsicle sticks glued and duct-taped together (glue keeps them from being taken apart by students). Then announce the materials costs: 10 single Popsicle sticks = $1, 5 double Popsicle sticks = $1, hot glue gun and glue stick = $1; additional glue stick = $1. Tell teams that they are not permitted to take apart the double Popsicle sticks.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students take a close look at truss structures, the geometric shapes that compose them, and the many variations seen in bridge designs in use every day. Through a guided worksheet, students draw assorted 2D and 3D polygon shapes and think through their forms and interior angles (mental “testing”) be...

Students learn about regular polygons and the common characteristics of regular polygons. Through a guided worksheet and teamwork, students explore the idea of dividing regular polygons into triangles, calculating the sums of angles in polygons using triangles, and identifying angles in shapes using...

Learn the basics of the analysis of forces engineers perform at the truss joints to calculate the strength of a truss bridge known as the “method of joints.” Find the tensions and compressions to solve systems of linear equations where the size depends on the number of elements and nodes in the trus...

Students learn about the fundamental strength of different shapes, illustrating why structural engineers continue to use the triangle as the structural shape of choice.

Copyright

© 2016 by Regents of the University of ColoradoContributors

Maia Vadeen; Malinda Zarske; Nathan Coyle; Ryan Sullivan; Andi Vicksman; Russell Anderson; Sabina SchillSupporting Program

CU Teach Engineering (a STEM licensure pathway), Engineering Plus Degree Program, University of Colorado BoulderAcknowledgements

This activity was developed by CU Teach Engineering, a pathway to STEM licensure through the Engineering Plus degree program in the College of Engineering and Applied Science at the University of Colorado Boulder.

Last modified: October 22, 2021

User Comments & Tips