Quick Look

Grade Level: 8 (7-8)

Time Required: 8 hours 15 minutes

(ten 50-minute periods)

Expendable Cost/Group: US $5.00 This activity also uses some non-expendable items such as a 3D printer, although simpler alternate fabrication materials and methods may be used instead.

Group Size: 2

Activity Dependency: None

Subject Areas: Problem Solving

NGSS Performance Expectations:

| MS-ETS1-1 |

| MS-ETS1-2 |

| MS-ETS1-4 |

Summary

Students design and develop a useful assistive device for people challenged by fine motor skill development who cannot grasp and control objects. In the process of designing prototype devices, they learn about the engineering design process and how to use it to solve problems. After an introduction about the effects of disabilities and the importance of hand and finger dexterity, student pairs research, brainstorm, plan, budget, compare, select, prototype, test, evaluate and modify their design ideas to create devices that enable a student to hold and use a small paintbrush or crayon. The design challenge includes clearly identified criteria and constraints, to which teams rate their competing design solutions. Prototype testing includes independent evaluations by three classmates, after which students redesign to make improvements. To conclude, teams make one-slide presentations to the class to recap their design projects. This activity incorporates a 3D modeling and 3D printing component as students generate prototypes of their designs. However, if no 3D printer is available, the project can be modified to use traditional and/or simpler fabrication processes and basic materials.Engineering Connection

Engineers use creativity and imagination to solve problems. People are living better and longer today thanks to biomedical engineers who develop new technologies in the health and medical fields such as assistive technologies, medicines and heart repairs. Like most engineers, biomedical engineers follow the steps of the engineering design project in their approaches to finding solutions to problems that directly relate to the human body. For real-world engineers, the design process typically includes a great number of iterative prototype versions and modifications en route to transform ideas into practical solutions. The design and development of assistive devices, such as eyeglasses, hearing aids, replacement limbs and wheelchairs, improve the quality of life for people with disabilities.

Learning Objectives

After this activity, students should be able to:

- Generate a solution to an open-ended design problem by following the steps of the engineering design process.

- Develop multiple solutions to a design problem.

- Describe/explain the impact of assistive devices.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-2. Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate competing design solutions based on jointly developed and agreed-upon design criteria. Alignment agreement: | There are systematic processes for evaluating solutions with respect to how well they meet the criteria and constraints of a problem. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: | Models of all kinds are important for testing solutions. Alignment agreement: The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: | |

Common Core State Standards - English

-

Draw evidence from informational texts to support analysis, reflection, and research.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Evaluate designs based on criteria, constraints, and standards.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Requirements for design are made up of criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Create solutions to problems by identifying and applying human factors in design.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Construct a prototype of a solution to a given design problem.

(Grade

7)

More Details

Do you agree with this alignment?

-

Generate and analyze data from iterative testing and modification of a proposed object, tool, or process to optimize the object, tool, or process for its intended purpose.

(Grade

7)

More Details

Do you agree with this alignment?

-

Present information that illustrates how a product can be created using basic processes in manufacturing systems, including forming, separating, conditioning, assembling, finishing, quality control, and safety. Compare the advantages and disadvantages of human vs. computer control of these processes.

(Grade

8)

More Details

Do you agree with this alignment?

Materials List

Note: Student teams determine their project materials, so material types, quantities and costs are variable. This design project activity is intended to utilize the resources of a design and/or prototyping shop or lab. If one is not available, the design project may be done in a typical classroom, with some modifications made to the activity.

To share with the entire class:

- computer with projector, to show Microsoft® PowerPoint® slides to the class

- computers with Internet access, for student research

- Microsoft® PowerPoint®, for groups to each make a final project summary slide

- notebooks (paper), pencils, rulers; for students to keep notes about the EDP and project

- materials for creating device prototypes, such as various woods, plastics, metals, cardboard, string and fabric

- various hand and machine tools for cutting, shaping, forming, joining, assembling and finishing prototype designs; such as rulers or tape measures, power or hand saws, and power or hand drills

- scale, for weighing materials and final prototypes

- 3D printer and filament (PLA or ABS)

- small paint brush and paint, or crayon, marker or colored pencil

- EDP Pre/Post-Test, two per student

- Engineering Design Process Graphic, Bill of Materials, Assistive Device Research Sheet, Decision Making Matrix, Tester Evaluation Sheet, one each per group

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/wpi_assistive_device_activity1] to print or download.Pre-Req Knowledge

Students should be familiar with 3D modeling and printing. However, the activity can also be modified to be conducted without using these technologies.

Introduction/Motivation

Have you ever thought about how important your hands are in everyday life? Probably not! When we don’t have problems with things, we tend to overlook their importance. We use our hands and fingers continuously, from the moment we get out of bed until we go back to bed at the end of the day. If you kept track of all the things you do for even half a day, you would probably be surprised by how much you depend on using your hands.

Now, think about what it would be like to do some of your everyday tasks without the use of your hands! You could even challenge yourself to experience this by taping up one of your hands—perhaps even your dominant hand—for part of the day so that you could not use it. How would that affect the things you need and want to do?

Some people have difficulty using their fingers and hands due to accidents, birth defects and various physical problems such as arthritis. Assistive devices can help people who have challenges or disabilities with their hands and need help doing things that require fine motor skills (that is, the coordinated use of hands and fingers).

Improving the quality of human life is an important aspect of engineering. Today, you will work as if you are biomedical engineers and use your creativity to design and develop an assistive device to help a person challenged by fine motor skills to hold a paintbrush or other drawing utensil.

Procedure

Background

This design project focuses on the development of an assistive device while being guided by the steps of the engineering design process (EDP). Assistive devices come in many different types and forms for many different needs. In the context of this activity, make it clear to students that an assistive device is something a person would use because of having a disability, not just because s/he may want to use the device. Assistive devices are intended to improve the quality of disabled persons’ lives. This project specifically focuses on a disability of the hand resulting in a fine motor skill deficiency.

The project is structured to follow the basic steps of the EDP: identify the problem, research the problem, develop possible solutions, select the best solution, build a prototype, test the prototype, communicate the results, redesign. This project also makes use of the resources provided by a general shop outfitted with various hand and power tools. As an alternative, the activity can be conducted in a modified fashion if no access to a shop or the suggested tools is available. For example, very simple prototypes can be constructed using cardboard and fabric to meet a more rudimentary proof of concept, and would only require simple tools, such as scissors, glue and rulers.

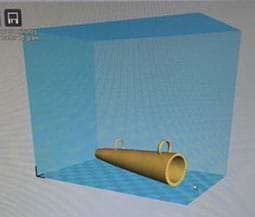

This activity also utilizes 3D modeling and printing. 3D modeling, sometimes referred to as solid modeling, is way to generate a design using digital means. It can be done using a variety of free or purchased software applications (including online versions) that function in an X, Y, Z, or length, width and height, environment. For example, instead of a student creating an image of a square or cube in a drawing program, they create a solid (3D) model that is sent to a 3D printer for output in a physical form. 3D printers have become reasonably priced for classroom use and user friendly for young students. The process of 3D modeling and printing relies on a connection between a computer, on which a student generates his or her design, and a 3D printer to turn the digital design into an object.

Note: The author used a free online resource called Tinkercad (www.tinkercad.com) with students for the 3D modeling and a New Matter MOD-t printer (https://www.treatstock.com/machines/item/78-mod-t) for the output of the prototypes.

Before the Activity

- Gather some materials (including adhesives and/or fasteners) that you want to offer students to use for their designs. Also consider requesting that students bring in some materials from home. These might include fabric, various plastics and woods, metal, cardboard, etc.

- Make copies of the handouts.

- Prepare the computer and projector to show the class the Assistive Artistic Device Project Slides (a PowerPoint® file) on Day 1 and Days 9-10.

With the Students: Day 1

- Divide the class into groups of two students each.

- Administer the pre/post-test on the topic of the engineering design process.

- Introduce (or review) the steps of the engineering design process (EDP). Show students slides 1-2 and/or the graphic handout. Direct students to copy the steps into their notebooks. The basic steps are: identify the problem, research the problem, develop possible solutions, select the best solution, build a prototype, test the prototype, communicate the results, and redesign.

- Introduce the problem statement (slide 3) for this activity’s design project: Design an assistive device for a disabled person to hold a paintbrush, crayon, marker or colored pencil.

- Introduce the project criteria (slide 3). Direct students to write down this information in their notebooks. The device must:

- Be safe

- Be durable

- Weighs less than 4 ounces

- Cost less than $5 to make

- Attach to a child’s hand or wrist

- Be easy to put on and use

- Hold a small paintbrush or drawing utensil

- Provide further tips and suggestions about some of the design requirements:

- About the weight limitation, take periodic weight measurements of your materials.

- About the cost constraint, keep track of the accruing costs by using the bill of materials.

- About the attachment requirement, take and document various hand and wrist measurements.

- Connect the problem statement to the engineering design process. This is Step 1: Identify the Problem. Explain that it is important to clearly identify the statement of need before beginning the design process.

- Include time for questions and discussion about the EDP and the project criteria.

Day 2

- Have student groups conduct Internet research to answer the 10 research sheet questions. This is Step 2: Research the Problem.

- Instruct students to begin brainstorming project ideas. This is Step 3: Develop Possible Solutions.

- Advise them to keep notes in a notebook, including rough sketches, ideas from research and simple sketches. Require that they come up with two different good solutions/plans for the device, which they will further evaluate to determine the best one to construct and test.

Day 3

- Student groups continue to brainstorm and develop possible solutions for their devices.

- As student generate ideas, have them use the decision making matrix to help them select the final design to develop into prototype. This is Step 4: Select the Best Solution.

- As students begin to identify potential materials, have them prepare a list of materials and how much of each, are required by their teacher-approved designs. As the designs evolve, expect students to research material costs and keep a running tally of overall costs on the bill of materials. Note: It can be challenging to determine a cost value for 3D-printed parts. However, certain programs (such as free, open-source Cura Software) can assess the gram weight of a design. Knowing the weight and the cost of the spool filament, the cost for a 3D-printed part can be calculated. For example, if a 1 kg spool of filament costs $30, the cost per gram is 3¢. If a design uses 32 grams of material, then the 3D-printed part (materials) cost is 96¢.

- As you guide students through materials selection for their designs, prompt discussions and deeper thinking about how various materials are flexible, rigid, brittle, hard, soft, elastic, slippery, durable, heavy, light, washable, waterproof, expensive, free, etc. Help students connect the idea of material properties to the specific project constraints. For example, materials that are brittle may not be a good choice due to the safety constraint. Likewise, paper may not be a good material due to the durability constraint.

- Work with the groups to review designs as they develop and then approve them when it is agreed that all design criteria are met.

Days 4-8

- Provide time for groups to build and evaluate their prototypes. This is Step 5: Construct a Prototype. Expect teams to require different amounts of time, depending on the complexity of design, availability of 3D printers, time needed for each print, etc.; you may need to be flexible with the time you provide. If necessary, have students create mock-ups with cardboard or other inexpensive materials before creating 3D-printed prototypes; doing this also has the benefit of helping students better explore, understand and determine how to attach their designs onto a hand or wrist.

- Monitor the shop/design lab space to help with supplies and materials, assist with any problems that arise, and monitor student use of tools and machines. Provide students with safety guidelines as well as tool and equipment use instructions.

Days 9-10

- Instruct students to evaluate and refine their prototypes against the original constraints—safety, durability, weight, cost, attachment, ease of use, secure utensil holding. This begins Step 6: Test and Evaluate the Solution.

- Explain that for each group’s prototype, three other students will conduct a performance assessment to evaluate the device while using it to perform the intended task, that is, painting with a small paintbrush. During the evaluation, the prototype must be tested without being held by the user in any way—so as to simulate its use by a person with fine motor skill disability. Direct students who evaluate another group’s device to fill out an evaluation sheet as part of the process. Ask the testers to each write on the evaluation sheet at least one constructive criticism about the prototype’s performance.

- Based on user feedback, give students time to revise or redesign their devices. This is Step 8: Redesign, or sometimes described as design iteration—when the design team goes back to earlier EDP steps like researching, brainstorming or selecting a different solution as it evolves towards an improved prototype design.

- Use the Teacher’s Final Prototype Grading Rubric to grade the final prototype devices. Which team was most successful? Which team had the most cost-efficient successful design? Consider making awards to the winners, giving recognition or special privileges.

- Have each group create one summary slide to communicate its design results. Show students slide 4, which lists the presentation criteria (the slide requirements):

- Title, including the device name

- List of the group member names

- Brief description of the design task

- Photograph that shows the device being used

- Labels and arrows to identify parts and materials

- Total cost of the device

- Final teacher rating for the device (max = 17)

- Have groups take turns presenting their slides to the class to communicate their results. This is Step 7: Communicate the Solution. Use the Presentation Scoring Rubric to grade the team presentations.

- Administer the pre/post-test again to gauge what/how much students have learned.

Vocabulary/Definitions

3D modeling: A type of computer software that makes use of three axes to create a digital file of a three-dimensional (3D) object.

3D printing: A prototyping method that creates a physical model from a digital 3D file by adding material in multiple, fine layers.

assistive device: A device designed to improve the life of a disabled person by helping him/her complete a task that s/he would not otherwise be able to do.

biomedical engineering: A creative field in which math and science knowledge is apply to develop solutions to problems in human life and medical care.

constraint: A restriction, requirement or limitation placed on a design.

criterion: A standard, measure or way by which something is evaluated or judged.

disability: An impairment that affects a person’s physical, intellectual, mental, sensory, social, developmental and/or emotional condition.

engineering design process : An organized, iterative process (series of steps) that guides engineers through the creation of a solution that meets the objective to solve a problem.

fine motor skill: The movement of small muscles in the human body, usually involving the coordination of hands and fingers with the eyes. Also called manual dexterity.

prototype: An early version of a design that converts an idea into a functional, physical model for evaluation or proof of concept.

rapid prototyping: A process used to quickly create a physical model from a computer-developed design, typically with a 3D printer.

Assessment

Pre-Activity Assessment

Pre-Test: Have students complete the seven-question multiple-choice EDP Pre/Post-Test to gauge their understanding of the engineering design process before beginning the project. This test will be given again at activity end.

Activity Embedded Assessment

Reflection Questions: During design and development, have students spend time reflecting on and answering the formative questions listed below. Either ask students to write their answers for teacher review or check their understanding through student/teacher discussion. Either way, the intent is to help students keep continual focus on the design process. Student answers also reveal whether they understand how the design process works. End each class period by having students do an exit activity or self-evaluation to monitor daily understanding and project progress. Expect teams to progress at different rates, with every group eventually addressing and achieving all the items below.

- Tell me how your design addresses each of the seven project criteria.

- Which of your two proposed designs did you choose? Why?

- How do you determine if something works or doesn’t work?

- Does the assistive device achieve the intended objective?

Post-Activity Assessment

Post-Test: Administer the EDP Pre/Post-Test again. Compare each student’s pre and post scores to determine his/her change in comprehension of the engineering design process.

Summary Presentations: Have design teams each create and present one-slide project recaps that meet the presentation criteria (slide 4). Use the Presentation Scoring Rubric to assess their slide content and presentation skills.

Safety Issues

- Train students how to safely use the hand and/or power tools.

- Have students wear eye protection when using hand and power tools.

Activity Scaling

- For lower grades, conduct the project without the 3D modeling component. Instead, have students fabricate their designs using simpler materials such as fabric and cardboard.

- For higher grades, consider using 3D modeling programs as SolidWorks and Autodesk Inventor, and require the designs to be more detailed and/or complex.

Additional Multimedia Support

A circular graphic of the engineering design process is available at http://www.doe.mass.edu/frameworks/scitech/2001/standards/strand4.html

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students work collaboratively to create a low-cost, easy-to-use device that helps individuals with multiple sclerosis (MS) securely hold a pencil, addressing difficulties with fine motor skills. After learning about MS and discussing how biomedical engineers develop assistive devices, students estab...

Students learn more about assistive devices, specifically biomedical engineering applied to computer engineering concepts, with an engineering challenge to create an automatic floor cleaner computer program. Following the steps of the design process, they design computer programs and test them by pr...

References

Massachusetts Science and Technology/Engineering Curriculum Framework. October 2006. Massachusetts Department of Education. http://www.doe.mass.edu/frameworks/scitech/1006.pdf#search=%22engieering%22

Copyright

© 2016 by Regents of the University of Colorado; original © 2016 Worcester Polytechnic InstituteContributors

Thomas Oliva; Terri Camesano; Kristen BilliarSupporting Program

Inquiry-Based Bioengineering Research and Design Experiences for Middle-School Teachers RET Program, Department of Biomedical Engineering, Worcester Polytechnic InstituteAcknowledgements

This digital library content was developed by Worcester Polytechnic Institute under National Science Foundation RET grant number EEC 1132628 in collaboration with the Worcester Public Schools. However, these contents do not necessarily represent the policies of the NSF and you should not assume endorsement by the federal government.

Last modified: December 9, 2022

User Comments & Tips