Quick Look

Grade Level: 7 (5-7)

Time Required: 30 minutes

Lesson Dependency: None

Subject Areas: Chemistry, Physical Science

NGSS Performance Expectations:

| MS-PS1-3 |

Summary

Students define and classify alloys as mixtures, while comparing and contrasting the properties of alloys to those of pure substances. Students learn that engineers investigate the structures and properties of alloys for biomedical and transportation applications. Students use the associated activity to practice their understanding by researching and communicating their findings of various alloys to be used in NASA aerospace applications. Pre- and post-assessment handouts are provided.Engineering Connection

Materials science and materials engineering go hand-in-hand when it comes to studying and designing materials for various applications. While a materials scientist investigates the correlations between the structure and properties of a given substance, a materials engineer uses this information to identify the most efficient way to enhance the properties of a material through the redesign of its structure. In this lesson, students experience the relationship between materials science and engineering through the investigation of alloys.

Learning Objectives

After this lesson, students should be able to:

- Define and classify alloys as mixtures.

- Compare and contrast the physical and chemical properties of alloys and elements.

- Determine the advantages of using alloys compared to pure substances

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

MS-PS1-3. Gather and make sense of information to describe that synthetic materials come from natural resources and impact society. (Grades 6 - 8) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This lesson focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Gather, read, and synthesize information from multiple appropriate sources and assess the credibility, accuracy, and possible bias of each publication and methods used, and describe how they are supported or not supported by evidence. Alignment agreement: | Each pure substance has characteristic physical and chemical properties (for any bulk quantity under given conditions) that can be used to identify it. Alignment agreement: Substances react chemically in characteristic ways. In a chemical process, the atoms that make up the original substances are regrouped into different molecules, and these new substances have different properties from those of the reactants.Alignment agreement: | Structures can be designed to serve particular functions by taking into account properties of different materials, and how materials can be shaped and used. Alignment agreement: Engineering advances have led to important discoveries in virtually every field of science, and scientific discoveries have led to the development of entire industries and engineered systems.Alignment agreement: The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions. Thus technology use varies from region to region and over time.Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Students will develop abilities to assess the impact of products and systems.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

Michigan - Science

-

K-7 Standard P.PM: Develop an understanding that all matter has observable attributes with physical and chemical properties that are described, measured, and compared Understand that states of matter exist as solid, liquid, or gas; and have physical and chemical properties. Understand all matter is composed of combinations of elements, which are organized by common attributes and characteristics on the Periodic Table. Understand that substances can be classified as mixtures or compounds and according to their physical and chemical properties.

(Grades

1 -

7)

More Details

Do you agree with this alignment?

Worksheets and Attachments

Visit [www.teachengineering.org/lessons/view/mis_alloy_lesson01] to print or download.Pre-Req Knowledge

Students should be familiar with the composition of matter and be able to define elements, compounds and mixtures. They should also be able to distinguish between physical and chemical properties, and be familiar with the periodic table of elements.

Introduction/Motivation

(Prior to the lesson, give students time to complete the Reviewing Pure Substances and Mixtures Pre-Assessment.)

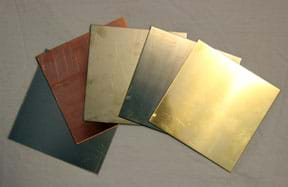

All substances on our planet can be classified as either pure substances or mixtures. In addition to the elements that make up the periodic table of elements, pure substances also include compounds that you encounter every day, like water. Mixtures include substances like Kool Aid and bronze. Bronze is a mixture of the elements copper and tin. Bronze is considered an alloy of copper. An alloy is a metal that is made by mixing two or more metallic elements, or made by mixing a metal and a nonmetal.

Let’s take a closer look and share the responses you wrote down for question three on the pre-assessment. What might be some advantages of using a copper mixture rather than using pure copper? (Pause for students to share responses.) As stated by some of you, when copper is mixed with other elements, forming alloys, some benefits might be to lower the materials cost and make it easier to produce the material. In order to understand the advantages of alloys, we are going to play the role of materials engineers who use their understanding of the properties of alloys in order to determine the ways in which they can be used. Refer students to the activity Alloy the Way to Mars to have them investigate different alloys and populate a class table with their findings and calculations of different material properties.

(Show students Table 1. Titanium and Its Alloys.) Using the information in this table, we can determine why—for a given application—it may be more beneficial to use an alloy rather than a pure substance. (Discuss the table as a class. Then proceed to Lesson Closure.)

Lesson Background and Concepts for Teachers

Alloys are created in order to enhance specific properties and characteristics of a given material. For example, the hardness, strength and corrosion-resistance of titanium are heightened when mixed with other substances, such as aluminum or chromium. Today, most commonly used metals are not pure; rather, they are alloys.

Since most design problems involve the selection of materials, it is important for scientists and engineers to study materials properties in order to understand and sometimes redesign the structure of a given substance. For example, an engineer who designs hip or knee replacement implants must understand the properties of a material to determine whether it will survive in the human body for a given period of time without side-effects to the person. A material used for hip replacement parts needs to be ductile, resistant to corrosion, biocompatible and, among other things, strong. Alloys are most often selected for such applications because of the properties they exhibit.

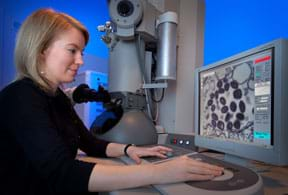

The properties of a given material are determined through a variety of means. Most often, they are investigated at the atomic level; x-ray diffraction and SEM (scanning electron microscope) imaging enable scientists and engineers to identify the extent of damage that may occur to a material from various testing scenarios, such as strength testing conducted in extreme temperatures. In the case of metals, correlations between the properties and the crystal structure (the manner in which atoms are arranged) are identified in order to determine the most suitable applications for the material.

Associated Activities

- Alloy the Way to Mars - Mirroring real-world engineering, student teams take measurements and make calculations for various metal alloys to determine their specific strengths and compile a class data table. After analysis of the class data, they write letters to NASA to communicate and defend their findings for the alloy they recommend be used to construct the engine and engine turbines for a space launch system being designed to transport astronauts to Mars.

Lesson Closure

As we learned from our examination of the properties of titanium and its alloys, when a pure substance (like titanium) is mixed with other elements, the material’s properties can be enhanced, resulting in its suitability for more applications. For example, with the creation of titanium alloy 6al-4v, hip replacements and engine turbines became a reality. With the support of materials scientists, materials engineers can design newer, more efficient alloys, and then apply these substances to broader applications. (Next, administer the summary assessment.)

Vocabulary/Definitions

alloy: A metal made by mixing two or more metallic elements, or by mixing a metal with a nonmetal. For example, bronze is a mixture of copper and tin, and steel is a mixture of iron and carbon.

atomic number: The total number of protons (positive charges) found in the nucleus of an atom of an element. Also the total number of electrons surrounding the nucleus of an atom of an element.

brittleness: A characteristic of a substance that is hard and rigid and breaks with smooth fractures, such as glass.

corrosiveness: The ability of a substance to deteriorate over time due to chemical means.

density: The amount of mass in a given volume; expressed in grams per cubic centimeter (g/cm3).

ductility: A characteristic of a substance that is malleable and can be physically changed without breaking, such as plastic.

element: A substance made of one type of atom, which cannot be broken down into smaller parts. For example, titanium (Ti).

malleability: A characteristic of a substance that describes its ability to be shaped and molded through hammering or pressing.

melting point: The temperature at which a substance melts.

mixture: A substance made by mixing two or more substances together. For example, bronze is a mixture of copper and tin.

oxidation: The ability of a substance to react with oxygen.

pure substance : A substance made of only one type of atom, or one type of molecule, or one type of compound. For example, gold (Au), oxygen gas (O2), or water (H2O).

reactivity: The ability of a substance to react with other substances.

Assessment

Pre-Lesson Assessment

Review: Before the lesson, give students time to complete the Reviewing Pure Substances and Mixtures Pre-Assessment, which asks them to categorize substances as either pure substances or mixtures, and explain the benefits of alloys. During the Introduction/Motivation section, ask students to share their answers. Students’ responses to the three questions reveal their base knowledge of the topic.

Lesson Summary Assessment

Concluding Questions: After the Lesson Closure, administer the Alloy Advantage Summary Assessment, which gives students a chance to show their comprehension of the learning goals. They define alloys, compare and contrast alloy properties to those of the elements from which they are composed, and explain the advantages of alloys. Review their answers to gauge their depth of comprehension before moving on to conduct the associated activity.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students gain a better understanding of the different types of materials as pure substances and mixtures and learn to distinguish between homogeneous and heterogeneous mixtures by discussing an assortment of example materials they use and encounter in their daily lives.

Students learn how to classify materials as mixtures, elements or compounds and identify the properties of each type. The concept of separation of mixtures is also introduced since nearly every element or compound is found naturally in an impure state such as a mixture of two or more substances, and...

To gain an understanding of mixtures and the concept of separation of mixtures, students use strong magnets to find the element of iron in iron-fortified breakfast cereal flakes. Through this activity, they see how the iron component of this heterogeneous mixture (cereal) retains its properties and ...

Students are introduced to the multidisciplinary field of material science. Through a class demo and PowerPoint® presentation, they learn the basic classes of materials (metals, ceramics, polymers, composites) and how they differ from one another, considering concepts such as stress, strain, ductile...

References

Callister, Jr., William D. Materials Science and Engineering: An Introduction (5th edition) New York, NY: Wiley, 2000.

Iron. (2015) Periodic Table of Elements: Los Alamos National Laboratory. Accessed July 14, 2015. http://periodic.lanl.gov/22.shtml

Knee Replacement Implant Materials. (2015) BoneSmart, Knee Replacement & Hip Replacement Patient Advocacy & Online Community, Foundation for the Advancement in Research in Medicine, Inc. Accessed July 14, 2015. http://bonesmart.org/knee/knee-replacement-implant-materials/

Ti-3Al-8V-6Cr-4Mo-4Zr (Beta C(TM)) technical datasheet. Edition date 07/01/2000. Carpenter Technology Corporation, Dynamet Holdings Inc. Accessed July 18, 2015. http://cartech.ides.com/datasheet.aspx?i=101&E=270

Titanium. (2015) Periodic Table of Elements: Los Alamos National Laboratory. Edition date 07/01/2000. Carpenter Technology Corporation, Dynamet Holdings Inc. Accessed July 14, 2015. http://periodic.lanl.gov/22.shtml

Titanium alloy Ti 6Al-4V technical datasheet. (2000) Accessed July 18, 2015. http://cartech.ides.com/datasheet.aspx?i=101&E=269

Wright, William J. Steel Bridge Design Handbook: Bridge Steels and Their Mechanical Properties. (November 2012) Publication no. FHWA-IF-12-052 - Vol.1 (archived), Office of Bridge Technology, U.S. Department of Transportation, Federal Highway Administration, Washington DC. Accessed July 18, 2015. http://www.fhwa.dot.gov/bridge/steel/pubs/if12052/volume01.pdf

Copyright

© 2016 by Regents of the University of Colorado; original © 2015 Michigan State UniversityContributors

Janelle OrangeSupporting Program

Robotics Engineering for a Better Life and Sustainable Future RET, College of Engineering, Michigan State UniversityAcknowledgements

The contents of this digital library curriculum were developed through the Robotics Engineering for a Better Life and Sustainable Future research experience for teachers under National Science Foundation RET grant number CNS 1300794. However, these contents do not necessarily represent the policies of the NSF and you should not assume endorsement by the federal government.

Last modified: May 27, 2019

User Comments & Tips