Quick Look

Grade Level: 7 (6-8)

Time Required: 1 hour

Lesson Dependency:

Subject Areas: Physical Science

Summary

Students learn about tensile strength. They review their knowledge of tension and focus on tensile loads and failure caused by them. They learn how composite materials are engineered to provide different characteristics, such as stiffness or strength.Engineering Connection

Engineers use their knowledge of materials and their properties (such as the ability to withstand tension and compression) to choose suitable materials in the design of safe, reliable and robust products and structures. They also design new materials and composite materials to provide different combinations of material properties.

Learning Objectives

- Students learn about tension as a force and how it acts on structural components through a hands-on group design problem (via the associated activity).

- Students learn about composite materials and how they can be made for increased strength.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

Common Core State Standards - Math

-

Describe qualitatively the functional relationship between two quantities by analyzing a graph (e.g., where the function is increasing or decreasing, linear or nonlinear). Sketch a graph that exhibits the qualitative features of a function that has been described verbally.

(Grade

8)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Refine design solutions to address criteria and constraints.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

State Standards

Massachusetts - Science

-

Demonstrate methods of representing solutions to a design problem, e.g., sketches, orthographic projections, multiview drawings.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Describe and explain the purpose of a given prototype.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain how the forces of tension, compression, torsion, bending, and shear affect the performance of bridges.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

-

Explain and give examples of how mass is conserved in a closed system.

(Grades

6 -

8)

More Details

Do you agree with this alignment?

Introduction/Motivation

What happens when you stretch a rubber band? What happens to the rubber band if you stretch it too far? (Listen to student responses.)

What are some other materials that are easily stretched? What are some that are not so stretchy?

The amount of force that a material can undergo before snapping is its tensile strength. When creating new buildings, bridges and other structures—or even smaller products such as washing machines, bicycles, chairs and cell phones— engineers choose materials and come up with designs that can withstand the tensile forces that they are expected to encounter.

Lesson Background and Concepts for Teachers

Before they break, structural elements subjected to tension (pulling forces) stretch and "neck down." The amount of elongation (stretching) depends on the load and the original length of the material. The longer the piece of material, the more it stretches when subjected to a given load (so it is important for all students to mark off the 5-inch initial length). Have students watch for the necking on their plastic samples that are loaded in tension; they should observe that the middle of the material gets skinnier and thinner. All materials in tension, even steel, stretches and necks down, before failing (breaking). When a high enough load is placed on a structural member in tension, the ultimate tensile strength of the material is exceeded and it fails.

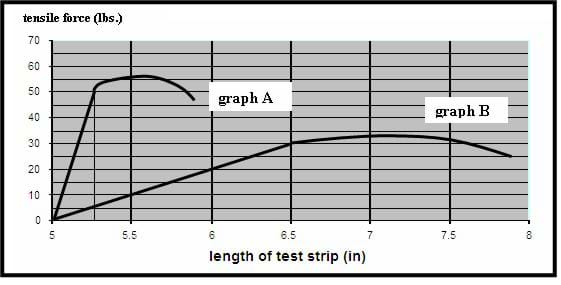

The stiffness of a material is a measure of its rigidity or flexibility; the greater a material's stiffness, the less it deforms (compresses, stretches, bends) when a certain load is placed on it. In this experiment, students are trying to develop not only a stronger material, but also one that has a much greater stiffness. Their graphs tell them if they are successful. The steeper the slope of the linear (straight-line) part of their graph, the higher the material's stiffness (see graph in Figure 1). A steep slope indicates a very rigid material—the amount of stretch increases slowly as the load increases—this is the goal for designing the chair webbing. Notice that material "A" only stretches 1/4-inch when loaded to 50 lbs. A curve with a less steep, flatter slope (graph B) indicates a more flexible or stretchy material—the amount of stretch increases quite a lot as the load is applied. Notice that material "B" stretches 1.5-inch with only a 30 lbs. load applied.

Composite materials are common today. They are created by bonding two or more materials together to make materials with different characteristics, such as stiffer, stronger, lighter, less thermal conductivity, higher electrical resistance, etc. Composite materials are found in all sorts of products, objects and structures, from building materials to sporting goods to spacecraft, and include fiberglass, ceramic and plastic materials. (See a list of examples under the Lesson Extension Activities section.) Refer to the Stop the Stretching activity to challenge students to design and test a new composite material.

Associated Activities

- Stop the Stretching - Students learn about composite materials, tension as a force and how they act on structural components through the design and testing of strips of plastic chair webbing.

Vocabulary/Definitions

force: A pushing or a pulling action that moves, or tries to move, an object.

internal stress : (internal force) Develops inside the materials that resist the outside forces and fight to hold the structure together.

load: An external force that acts upon a structure.

structure: Something built or constructed so as to hold up weight and withstand forces placed on it. Examples: Buildings, dams, planes, bicycle frames, keyboards, artificial tissues, medical implants.

tension: Two pulling forces, directly opposing each other, that stretch an object and try to pull it apart. For example, pulling on a rope, a car towing another car with a chain – the rope and the chain are in tension or are "being subjected to a tensile load."

Assessment

Post-Introduction Reflection 1: Give students five minutes to sit quietly and think of five real-life examples of structural elements in tension, and write them down on paper. Then together as a class, go around the room having students one-at-a-time name items on their lists. Discuss and write the ideas on the board, until no new ideas are presented. Possible answers: cables (wire ropes) that hold up bridges, antennas and small tower, and used in cranes and hoists; telephone and cable lines hanging between poles and houses; wires that hang or support signs and traffic signals, or hold up sailboat masts; ropes with pulleys that lift heavy loads (block and tackle), or rope ladders, playground equipment and boat rigging. And what about other smaller everyday items that are also elements in tension, such as hammocks, swings, chairs or skateboards?

Post-Introduction Reflection 2: In a similar fashion to the previous reflection activity, do the same, but ask students to come up with examples of real-life uses of engineerd composite materials. (See a list of examples under the Lesson Extension Activities section.)

Closing Discussion: Individually or as groups, assess students' understanding of the concepts taught in class using the Investigating Questions located in the associated activity.

Lesson Extension Activities

Have students research different composite materials to find how they are made, what they are used for and a description of their improved properties. Example composite materials to research: reinforced concrete, insulation and other building materials; materials used to make skis, snowboards, racing bicycles, tennis rackets, fishing poles and golf clubs (sporting goods, equipment and protective gear); materials used to make spacecraft, airplane and automotive bodies. Specific materials to research: glass fiber-reinforced resins (fiberglass), carbon-graphite composites, ceramic composites, plastic laminates and plastic-metal laminates, and many others.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!Copyright

© 2013 by Regents of the University of Colorado; original © 2005 Worcester Polytechnic InstituteContributors

Douglas Prime, Tufts University, Center for Engineering Educational OutreachSupporting Program

Center for Engineering Educational Outreach, Tufts UniversityLast modified: June 6, 2019

User Comments & Tips