Quick Look

Grade Level: 10 (9-11)

Time Required: 16 hours 45 minutes

This project works well as the final design project of an introductory high school engineering course, taking about twenty 50-minute time periods over five weeks.

Expendable Cost/Group: US $50.00 Project costs vary widely, depending on student project design. The entire class is considered the "group size" because smaller teams build sub-components that come together to create one class prototype.

Group Size: 4

Activity Dependency: None

Subject Areas: Measurement, Problem Solving, Science and Technology

NGSS Performance Expectations:

| HS-ETS1-2 |

| HS-ETS1-3 |

Summary

In this service-learning engineering project, students follow the steps of the engineering design process to design a vision testing device. More specifically, they design a prototype machine that can be used to test the peripheral vision of partially-blind, pre-verbal children. Students learn about the basics of vision and vision loss. They also learn how a peripheral vision tester for adults works (by testing the static peripheral vision in the four quadrants of the visual field with four controllable lights in specific locations). Then they modify the idea of the adult peripheral vision tester to make it usable for testing young children. The class designs and builds one complete prototype, working in sub-groups of four or five students each to build sub-components of the project design.Engineering Connection

Biomedical engineers and doctors work closely together to design machinery for medical care workers to use to diagnose and treat patients. Doctors give engineers device requirements and the engineers work under a set of constraints to design equipment to meet those requirements. The resulting biomedical products may take the form of devices, implants, machines, medicines and technologies (diagnostic equipment, pacemakers, artificial limbs, surgical techniques, hearing aids, laser eye surgery, ultrasound, amniocentesis, in-vitro fertilization, pain medicine, etc.). As part of their design work, engineers create prototypes and make technical presentations, to learn, test and communicate their work.

Learning Objectives

After this activity, students should be able to:

- Explain different steps of the engineering design process.

- Explain how engineers design and create devices for the benefit of people.

- Explain how peripheral vision is tested.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | Engineers continuously modify these technological systems by applying scientific knowledge and engineering design practices to increase benefits while decreasing costs and risks. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Illustrate principles, elements, and factors of design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Develop a plan that incorporates knowledge from science, mathematics, and other disciplines to design or improve a technological product or system.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

This materials list is what the students at one high school came up with when creating this device. Since this is an open-ended project, your students will generate a different list of materials, but many items may be similar.

When this project was taught, the class was divided into subgroups. The "structure" group was responsible for creating the framework onto which everything was mounted. The "lights" group was responsible for wiring the lights to dimmer switches and finding a way to mount them to the structure. See their materials lists below.

For the Structure Group:

- 0.5-inch thin wall PVC pipe, 3 m length

- 4.5-inch PVC elbow joints

- 2.5-inch PVC T-joints

- 1.25-inch thin wall PVC pipe, 1 m length

For the Lights Group:

- 4 60-watt B-type blunt-shaped decorative light bulbs

- 4 indoor extension cords

- 4 light bulb sockets

- 4 dimmer switches

- power cord with 4 outlets

- balsa wood to make 24 x 12 x 8 cm box to hold dimmer switches

- 0.25-inch thick foam, 10 x 15 cm block

Tools for the class to share:

- drill

- plastic welder epoxy

- epoxy

- saw

- electrical tape

- wood glue

- Xacto knife

- wire cutters

- (optional) dremel

For all students:

- butcher paper, pens and pencils, for brainstorming and sketching

- (optional) Pre/Post Quiz, two copies per student

- Project Requirements and Constraints, one per team

For the teacher:

- (optional) Evaluation / Grading Rubric, one per team

- (optional) computer with internet to show online video

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_service_activity02] to print or download.Pre-Req Knowledge

Students should be familiar with the engineering design process and preferably have completed an engineering design project prior to this activity. It is helpful to go through a smaller-scale project first, such as that described in TeachEngineering's Creative Engineering Design unit.

Introduction/Motivation

(In advance of this project, find a local physician to be your client for this vision tester project, and then personalize the introduction, below, to reflect your project details. Otherwise, use the example below, with the Anchor Center in Denver as the client. To introduce the activity, show students a seven-minute video that is available on the main page of the Anchor Center's website. See https://www.anchorcenter.org/.The video helps to orient students to an example of everyday human medical challenges that exist, giving a context for the activity's engineering problem-solving message.)

([optional] For a simple demonstration, have handy a punch bowl or other half-dome shaped item.)

Who can name some things that engineers create? (Possible answers: Cars, bridges, computers, replacement arms and legs, biomedical devices, cleaning agents, roller coasters, appliances, tools.) Who can name one thing than an engineer has built that helps make the community a better place? (Possible answers: Shelters, community playgrounds, water treatment plants, school heating and cooling systems, bridges, etc.) As it turns out, engineers design and build many things for the benefit of society and to help make the world a better place to live.

A center for blind children in Denver needs our help. The Anchor Center for Blind Children is a non-profit organization that helps visually-impaired children reach their highest potential. The center has a staff of vision specialists, therapists and teachers, and an optometrist (eye doctor) who visits the center weekly to conduct vision testing on the children. But the doctor has a problem. While he has the tools to test children's vision loss in forward vision, he is unable to test their peripheral vision. Imagine looking through paper tubes with each eye — that gives you an idea of how your vision would be limited if you lost your peripheral vision.

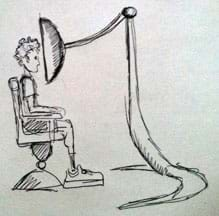

The doctor has asked us to design and build him a device to test the peripheral vision of non-verbal infants (children who are too young to speak). Peripheral vision testers for adults consist of a half dome into which a person positions his/her head in the center in such a way that each point on the dome is one-third of a meter away from his/her eyes (see Figure 1). (At this point, a visual demonstration using a punch bowl or other half-dome shaped item is helpful.) The doctor then turns on various lights in the dome and the adult hits a button whenever s/he sees a light. This informs the doctor of the extent of a person's peripheral vision.

Unfortunately, it is impossible to explain these instructions to an infant or non-verbal child, or have them communicate to the doctor what they see, so a different type of machine must be built. Ideally, the machine would mimic the adult machine closely and have lights in each quadrant of the field of vision. The brightness of these lights must be controllable by the doctor as must the size of the light beam seen by the child. The doctor envisions a parent holding the child in his/her lap while the test is being administered. The doctor must be able to see the child's head and eyes during the test in order to observe reactions when the lights are turned on and off. To be able to create results that correlate to a normal peripheral vision tester, the lights should be roughly one-third of a meter away from the child's eyes.

Your goal, as engineers, is to design and build the world's first peripheral vision tester for non-verbal children. Your product requirements and constraints have been outlined by the doctor and additional constraints are your time, budget (materials) and workforce. You will follow the time-tested steps of the engineering design process to create this device. The first step is already done, which is to identify the need. Next, we'll be researching the problem; imagining: developing possible solutions; planning: selecting a promising solution; creating a prototype; testing and evaluating the prototype; and improving and redesigning as needed.

Procedure

Background

As a group, the class designs and builds one complete prototype, working in sub-groups of four or five students each to build sub-components of the project design.

Service-Based Engineering: Service-based engineering design projects involve finding a client in the community with a specific need and designing a project to fulfill that need. By engineering for a specific community need, students become more emotionally invested in the project and gain an understanding that engineering is directly linked to helping people. We have observed that service based engineering projects increase female students' interest in engineering, compared to traditional engineering projects, while not deterring male student engagement.

In advance of this project, find a local physician to be your client for this vision tester project, and then personalize the activity to reflect your project details. Otherwise, use the provided example with the Anchor Center in Denver.

Be open to variations on this service-based engineering project. For example, you might work with a school theater group to help them prepare a lighting system for a play. The requirements would involve similar needs for lighting effects and controls, coordinated with structure design and user interface.

Anchor Center for Blind Children: The Anchor Center for Blind Children, located in Denver, Colorado, is a center for children, infants through five-year-olds, who have vision loss. The non-profit organization helps visually-impaired children reach their highest potential. The staff includes vision specialists, therapists, teachers and an eye doctor who visits the center weekly to perform vision testing on the children. The doctor has equipment to test the center vision of children, but not to accurately test the peripheral vision. To introduce the activity, show students a seven-minute video that is available on the main page of the Anchor Center's website. The video helps to orient students to examples of everyday human medical challenges that exist, giving a context for the activity's engineering problem-solving message that engineers help people by solving problems in our communities. See https://www.anchorcenter.org/

Requirements and Constraints Set by Eye Doctor: The peripheral vision tester must have one light in each of four quadrants that can be controlled by the person administering the test. Locate the lights approximately one-third of a meter away from the child's eyes and mount them in such a way that a parent can sit holding his/her child in front of the device and have the lights centered on the child's head. This can be done by creating a dome or a flat square with the lights mounted in the corners. Make the light brightness adjustable by the tester. During the testing, the doctor must be able to watch the eyes and head of the child to see if s/he reacts to the lights being turned on and off.

Vision: Most people who are legally blind, which is defined as worse than 20/200 vision, are not completely blind. Many of the diseases that cause vision loss (such as glaucoma) cause a loss of peripheral vision but do not cause complete blindness.

Currently, no device exists to test the peripheral vision of non-verbal children. Existing devices for adult peripheral vision testing rely on a person to press a button when s/he sees a light in his/her peripheral field of vision. Since very young children cannot do this, a peripheral vision tester for them must be designed so the doctor can watch a child's eye and head movements as lights in different vision quadrants are turned on/off.

Engineering Design Process: The engineering design process is a set of steps that engineers use to design and create a design solution or product. The steps for this project are as follows:

1. Ask to Identify the Need and Constraints: In this case, the need is for the design and creation of a device to test the peripheral vision of non-verbal children such that the doctor can watch the child's eyes during testing. What are the constraints? (Physical: Lights must be one-third of a meter away from the eyes, one light in each of four vision quadrants, controllable by the doctor while s/he watches the patient's eyes; your budget; time available; team member designers.)

2. Research the problem: Gather more information. What do we need to research and understand about eyes and adult peripheral vision testers? For this project, see the attached Project Requirements and Constraints as put forth by the optometrist. Most peripheral vision testers are composed of a closed half-dome so the doctor is unable to see eye movement (see Figure 1). The testing depends upon the subject communicating with the doctor when s/he sees a light.

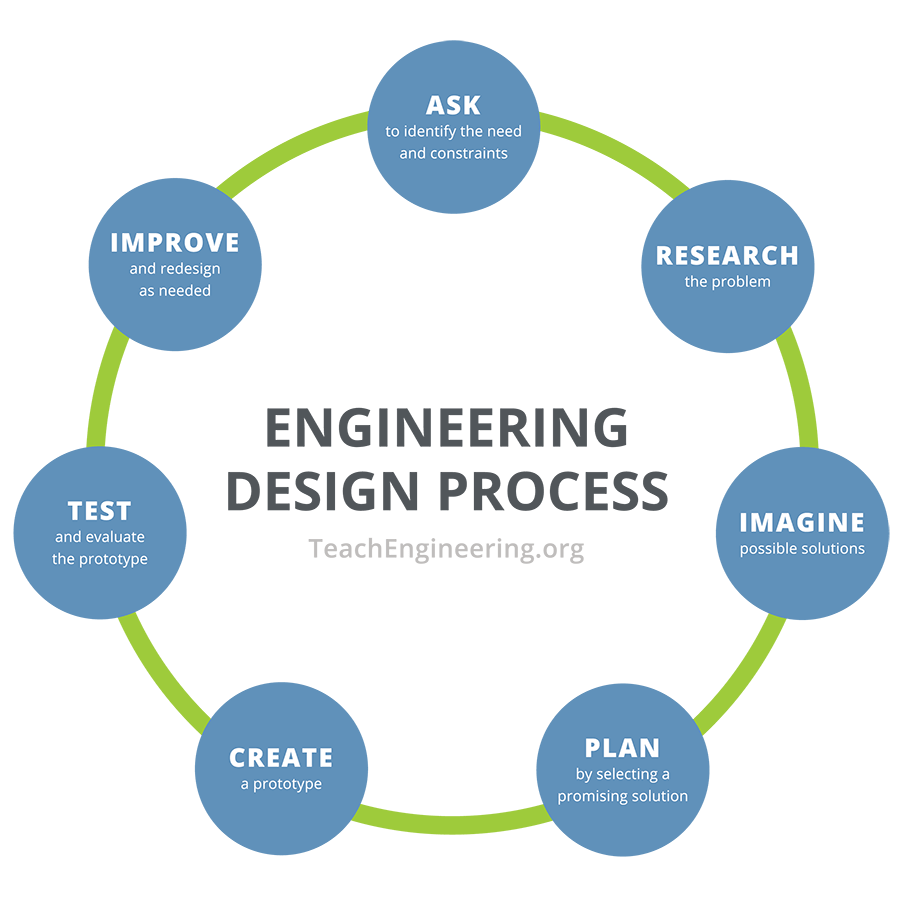

What needs to be done? (Create a class task list as described in the With the Students section.) Determine how much time to spend brainstorming and researching the problem. (This ultimately depends on how much time is allotted for the entire project. See suggested schedule in Figure 2, a summary of the steps described in the With the Students section.) How much time should be spent building the first prototype? (Again, this is dependent on the time allotted for the entire project, but in the end, usually takes longer than expected.) Will time be left to redesign the prototype? (Generally, redesign is an ongoing, iterative process during the building phase as certain ideas become too complicated and roadblocks are avoided.)

3. Imagine Possible Solutions: This is the brainstorming stage when all ideas are good ideas. Encourage wild ideas. Do not judge ideas. Write everything down.

4. Plan: Select a Promising Solution: Determine what each concept would take to complete. List the pros and cons of each concept and determine whether they fit the project requirements and constraints. Every engineering project has certain constraints. This project is constrained by materials, time and people. The most promising solution fulfills all the requirements while working within the constraints.

5. Create the prototype: A prototype is a working version of the final product. It is used to demonstrate the concept, and for this project, is the final deliverable product. Prototypes are also used as models to manufacture final products.

6. Test and Evaluate the prototype: The prototype must fulfill the requirements decided upon at the beginning of the project. Does the device work as expected?

7. Improve and Redesign as Needed: Most engineers go through the steps of the design process several times before reaching a final design solution or product. Redesigning is essentially another version of "recognizing the need," which is the beginning of the design loop. Keep modifying the design until it meets the requirements within the given constraints.

Before the Activity

- Gather butcher block paper, pens and pencils.

- Make copies of the attached Pre/Post Quiz (optional) and Project Requirements and Constraints.

With the Students

1. (optional) Hand out the quiz for students to complete before starting the project.

2. Present the Introduction/Motivation section to the class to set the design challenge scenario of the Anchor Center and testing the peripheral vision of pre-verbal children. Hand out the Project Requirements and Constraints.

3. Have students conduct online research on how adult peripheral vision testers typically work. Find out: the location of the lights (several in each of four quadrants), the shape of the structure (dome), the maximum size of the lights (~2 cm), the maximum brightness of the lights, etc. (30 minutes)

4. As a class, discuss the parameters of the problem. Decide which elements of the project are most important, such as having four lights in the four vision quadrants that turn on/off, and which elements are less important, such as being able to adjust the brightness of the lights or change the size of the light. (30 minutes)

5. Divide the class into groups of four or five students each and brainstorm possible ways to design this device. Have each group brainstorm ideas for the entire device, not just sections of it. Give each team a sheet of butcher paper and encourage students to write down or draw all of their ideas. Encourage wild ideas as well as building upon each others' wild ideas. Remind everyone to be open to all ideas during this stage. (30 minutes)

6. Have each group draw its favorite idea on a sheet of butcher paper. Make sure the drawings are large enough for class presentation. (15 minutes)

7. Have each group present its favorite idea to the class. Have students explain why they chose that design and why they think it will work. Have students also talk about where they anticipate running into trouble building their idea. Allow two or three minutes per presentation with time after each presentation for the class to ask questions and critique the idea. Leave the design drawings at the front of the classroom.

8. After each group is done presenting their ideas, begin a class discussion to determine which ideas are the most feasible, alone or in combination, to build as the final agreed-upon design. Let this discussion be student-run. Depending on the ideas presented, this process may take 15 to 60 minutes.

9. As a class, list everything that must be done to create this project. The length of this list depends on how complex the students intend the project to be. Remind them (frequently) that they have a time constraint. The list might include tasks such as: wire lights, mount lights, build structure, build base, build user-interface, etc. (15 minutes)

10. Once the task list is complete, categorize tasks into several main sub-projects, such as: light wiring, light mounting, aperture control, structure, user interface, etc. Hopefully, the class has enough students so groups of four or five students can oversee each sub-project. Specify on the classroom board each group's responsibilities. Have students write down their top three choices for sub-projects to work on and form new student groups, accommodating their preferences as much as possible.

11. Have each group create a detailed design of their piece of the project that includes lengths, widths, diameters, etc. Make sure inter-group communication occurs to coordinate the pieces that must fit together. Make sure that the group building the aperture is communicating with the group building the structure and that the group wiring the lights is communicating with the group designing the user interface. (60 minutes)

12. Set a deadline by which time teams must prepare initial materials lists. Direct the students to be as specific as possible when creating the lists. Review each list with the group to make sure the person buying the materials understands exactly what is needed.

13. Building phase: Once materials have been gathered, have the teams start to build. When conducted with a class of 15 students, the following building procedure was followed:

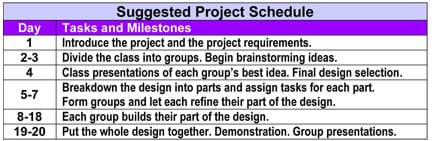

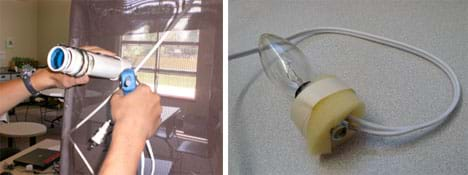

- Structure Group: The structure group is responsible for creating the framework for the project. Their major goal is to create a free-standing structure onto which four lights can be mounted such that each light is approximately one-third of a meter away from the eyes of the child being tested. Example solution: A square of half-inch diameter PVC pipe was constructed using four PVC elbow joints (see Figure 3). The side-length of the square was approximately two-thirds of a meter so that each light would be approximately one-third of a meter away from the child's face. A small kickstand was made of PCV pipe and attached at the base so the structure would be free standing. Light mounts were made from 1¼-inch diameter PVC pieces about 15 cm in length attached at the corners of the square using plastic welder.

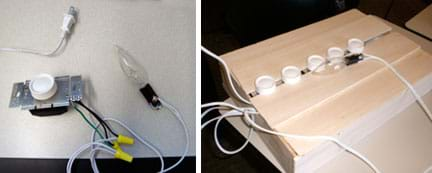

- Lights Group: The lights group is responsible for wiring lights to dimmer switches and working with the structure group to mount the lights onto the structure. They are also responsible for building a box to hold the dimmer switches and creating a user interface. Example solution: A dimmer switch was connected in the middle of a standard indoor extension cord by cutting the cord in half and rewiring. The end of the extension cord was wired to a light socket. The dimmer switches were mounted into a box built of balsa wood and plugged into a power cord that was also housed in the box. (See Figure 4.)

- Aperture Group: The aperture group is in charge of creating a device to control the size of the light beam emitted from the light mount. They must work closely with the structure group to make sure its device fits seamlessly onto the light mounts. Example solution: A flip down aperture was created for each light. The aperture was a ring of 1¼-inch PVC pipe with a sheet of black rubber (aluminum foil would also work) covering half of the hole. The ring was attached with a hinge to the light mounts on the structure. The lights sockets were wrapped in a foam covering and covered in electrical tape to ensure a snug fit into the PVC (see Figure 5). The lights could be slid into the light mounts and easily removed for storage.

14. Determine milestones for each group. Examples:

- For the Structure Group, set a deadline for when the structure must be finished and a second deadline for when the light mounts must be attached. Suggested times are two and four hours after materials are received, respectively.

- For the Lights Group, set a deadline for when the lights must be wired to the dimmer switches, a second deadline for having the box for the user-interface built, and a third deadline for devising a method for mounting the lights onto the structure. Suggested times are two, three and five hours after materials are received, respectively.

- For the Aperture Group, set a deadline for when the freestanding device is finished, and a second deadline for when it is mounted to the light mounts. Suggested times are four and five hours after materials are received, respectively.

15. After the class prototype is built, have students set up a test subject and make sure that all the basic requirements are being met. Choose a student to be a test subject and have another student measure both the horizontal and vertical distance from the subject's eyes to each of the lights. Have the students use trigonometry to determine the distance from the light. Alternatively, have students measure the distance from the subject's eyes to each of the lights to make sure they are approximately one-third of a meter away.

16. When the project is finished, have students present it to a larger audience. Have them explain their initial design and how they expected it to work. Then have them present their final design and explain how it differed from their original one and why. Finally, have them explain what they would change given more time. Alternatively, have them videotape a demonstration of their final project and give an explanation of it as if they were to send the video and the device to the Anchor Center for Blind Children or a similar facility.

17. (optional) At project end, hand out the quiz for students to complete.

Vocabulary/Definitions

aperture: A device controlling the amount of light that passes through an opening by changing the size of the opening. For example, cameras use apertures to make sure film is correctly exposed.

constraint: A restriction or limitation on the degree of freedom one has in providing a solution to problem or challenge.

glaucoma: An eye disease in which a person loses his/her peripheral vision.

optometrist: A doctor specializing in the field of vision.

peripheral vision: Vision outside the center of the gaze.

requirement: What a particular product or service should do. It is a statement that identifies a necessary attribute, capability, characteristic or quality. In engineering, sets of requirements are inputs into the design stages of product development.

vision quadrant: A portion of a person's field of vision when it is divided into four equal-sized, non-overlapping spaces or "quadrants," separated by right angles.

Assessment

Pre-Activity Assessment

Pre/Post Inventory Quiz: As necessary, personalize the attached concept inventory Pre/Post Quiz with topics pertinent to the class's service-based engineering design project. Before beginning the project, have students complete the quiz. At completion of the project, have students take the same quiz, comparing their results to their pre-project scores to gauge their knowledge gains.

Engineers Help the World by...: Have every student write "Engineers help the world by..." at the top of a sheet of paper. Then, have them list some things that engineers design and build for the benefit of humanity and our world. Call on students to share some of their ideas with the class. Talk about how engineers build things for the benefit of society and create things that directly help people live more comfortable, healthy, happy and/or safe lives.

Activity Embedded Assessment

Design Review: At regular intervals, have groups give the class progress reports. Have teams explain what they have accomplished since the last report and what they plan to accomplish during the next time period. Give the class a chance to comment on and critique what was presented. Have students use the attached Presentation Peer Review Form to give feedback. Use the attached Evaluation/Grading Rubric to grade the project.

Post-Activity Assessment

Project Reflection: Have students answer the following questions:

- What did you design and build, and why?

- What was your role in the group? What were the other roles in the group?

- How well did your group work together?

- How well did the different groups communicate together?

- What would you change about your design if you had more time and materials?

Pre/Post Inventory Quiz: After completion of the project, have students take the same concept inventory Pre/Post Quiz that they took before starting the project. Compare their scores to their pre-project scores to gauge their knowledge gains.

Safety Issues

The use of power tools and sharp blades are necessary to complete this project. Make sure students know how to use the tools safely and actively supervise them.

Troubleshooting Tips

If the light bulbs are positioned too close to the PVC pipes or left on for long time, the PVC may melt.

Inevitably, initial materials lists are incomplete. Be prepared to make multiple trips to the supply stores as the design evolves and changes during the building phase.

Additional Multimedia Support

For more information on high school engineering design process activities and projects, see TeachEngineering's Creative Engineering Design unit.

Learn more about the steps of the engineering design process at the Engineering is Elementary website: http://www.mos.org/eie/engineering_design.php

Learn more about the engineering design process at https://www.teachengineering.org/engrdesignprocess.php

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students examine the structure and function of the human eye, learning some amazing features about our eyes, which provide us with sight and an understanding of our surroundings. Students also learn about some common eye problems and the biomedical devices and medical procedures that resolve or help...

Students are introduced to the Robotics Peripheral Vision Grand Challenge question. They are asked to write journal responses to the question and brainstorm what information they require in order to answer the question. Students draw a basis for the average peripheral vision of humans and then compa...

Copyright

© 2009 by Regents of the University of ColoradoContributors

Eszter Horanyi; Alison Pienciak; Jonathan MacNeil; Stephanie Rivale; Malinda Schaefer Zarske; Denise W. Carlson (This activity was taught at the Denver School for Science and Technology.)Supporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under grants from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education, and National Science Foundation (GK-12 grant no 0338326). However, these contents do not necessarily represent the policies of the Department of Education or National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: September 30, 2021

User Comments & Tips