Quick Look

Grade Level: 4 (3-5)

Time Required: 45 minutes

Expendable Cost/Group: US $2.00

Group Size: 2

Activity Dependency: None

Subject Areas: Geometry, Physical Science, Problem Solving, Reasoning and Proof, Science and Technology

NGSS Performance Expectations:

| 3-5-ETS1-3 |

Summary

Students continue their pyramid building journey, acting as engineers to determine the appropriate wedge tool to best extract rock from a quarry and cut into pyramid blocks. Using sample materials (wax, soap, clay, foam) representing rock types that might be found in a quarry, they test a variety of wedges made from different materials and with different degrees of sharpness to determine which is most effective at cutting each type of material.Engineering Connection

An important job for any engineer is to assign appropriate tools for building, machining and manufacturing. A wrong choice may result in a poor quality final product and/or a tool that wears out or breaks quickly. For example, a dull wooden wedge used to cut solid rock is only successful for a short time before it breaks or wears down to the point at which it no longer cuts. Engineers calculate the amount of force required to cut through a given material; knowing this helps them choose the most appropriate tool material that will cut through the rock material.

Learning Objectives

After this activity, students should be able to:

- Determine how different materials break using differently-angled wedges.

- Describe why simple machines are used and how a wedge exerts a force.

- Demonstrate why material selection and material science is important to engineers.

- Understand that because simple machines do their jobs so well they are still used today.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-3. Plan and carry out fair tests in which variables are controlled and failure points are considered to identify aspects of a model or prototype that can be improved. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Plan and conduct an investigation collaboratively to produce data to serve as the basis for evidence, using fair tests in which variables are controlled and the number of trials considered. Alignment agreement: | Tests are often designed to identify failure points or difficulties, which suggest the elements of the design that need to be improved. Alignment agreement: Different solutions need to be tested in order to determine which of them best solves the problem, given the criteria and the constraints.Alignment agreement: | |

International Technology and Engineering Educators Association - Technology

-

Design solutions by safely using tools, materials, and skills.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- 1 soap or wax block (~5 cm x 5 cm)

- 1 clay block (~5 cm x 5 cm)

- 1 foam block (~5 cm x 5 cm)

- 1 Styrofoam block (~5 cm x 5 cm)

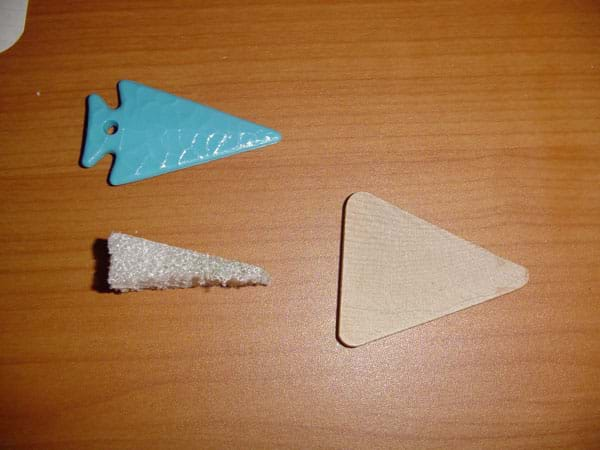

- Wooden wedge (approximately the size of a typical doorstop [5 cm x 10 cm x 5 cm])

- Balsa wood wedge (~3 cm x 3 cm x 6 cm)

- Plastic wedge (~3 cm x 3 cm x 6 cm)

- Styrofoam/foam wedge (~3 cm x 3 cm x 6 cm)

For the entire class to share:

- A variety of demonstration wedges with different angles and materials. For example, a plastic knife, putty knife, table knife, metal screwdriver or chisel (and a small hammer to use with the chisel).

- Some demonstration quarry material. For example, a half stick of cold margarine, a brick, etc.

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/cub_simple_lesson02_activity1] to print or download.Pre-Req Knowledge

General knowledge of pyramids and geometric angles. Familiarity with the six simple machines introduced in Lesson 1 of this unit.

This unit's lesson, Pyramid Building: How to Use a Wedge, does not need to be completed prior to students doing this activity, but the storyline of creating a pyramid created within the lesson helps students understand what they are trying to achieve with this activity.

The pyramid site choosing activity in Simple Machines: Lesson 1, is also not required, but it provides students with a background so they understand what a rock quarry is, and from where they are trying to extract the rock and why.

Introduction/Motivation

The wedge is a simple machine that helps make our lives easier. Does anyone know how a wedge helps us do work? (Answer: A wedge allows us to split materials apart much more easily then we could do by hand.) The wedge gives us a mechanical advantage. This means that we have to exert less force to complete the task, but we usually have to go a greater distance. For example, when you use an axe to cut through a log, the job is much easier then if you tried to break the log just with your hands. However, you also have to make many axe cuts to get through the wood. The axe allowed you to cut through the wood easier, but you had to make more cuts to do it.

The wedge is slightly different from other simple machines because when you are using a wedge as a tool, often times another object is required to help. For example, if you were using a nail, which is a very sharp-angled (acute) wedge, a hammer would be required to force the nail into the wood. This is similar to the way we believe ancient pyramid construction was done. The pyramid builders found large rock quarries filled with different types of rock. They had to figure out a way to break the rocks away from the quarry wall into large bricks (stone blocks) that could be used to build the pyramid.

Pyramid builders would likely find a variety of different rock types within the quarry. They had to engineer a wedge that could be used to break away the rock from the quarry wall. If they encountered a soft, clay-like material, pyramid engineers designed a large wedge made of wood which could easily cut through clay-like material and successfully make many bricks. But, when they came across hard marble in their quarry, the wooden wedge would not break the material apart well. The wedge quickly wore down and the engineers knew that they must design a more effective wedge. That's where you come in. Today you are going to be design engineers and help research wedge designs that help the pyramid builders cut through each type of rock they encounter.

Show students an excellent animation of a Polish video about transportation methods that do not use a wheel and axle: https://www.youtube.com/watch?v=R_mGXrHQs9M. The animation shows how heavy stone blocks might have been systematically moved up an incline plane (ramp) using many human-powered wedges. The large supply of Egyptians workers would have made this method possible.

Through this activity, you will learn about different types of wedge angles and the different materials from which wedges can be made. You will experiment with a variety of materials so that you will be able to make recommendations to the pyramid engineers about how to best design a wedge. You will also see why it is so important for engineers to understand the design process and material selection when they are working on a project. If you choose the incorrect material for your wedge, the tool will not work well and your project may not be successful.

Procedure

Before the Activity

- Gather teacher demonstration materials.

- Prepare student group activity materials.

- Before making copies of the The Wedge Worksheet, fill in the table column descriptions with the wedge materials the students will be using, for example "wood," "plastic" and "Styrofoam" (or have the students do this). Fill in the row descriptions with the type of rock material the students will be using, for example, "foam," "wax" and "clay" (or have the students do this).

With the Students

- Teacher Demo: To give the students a visual understanding of a wedge and how it can be used as a tool, lead a demonstration using wedges as cutting tools. For the demo, the material being cut should be at a larger scale than what the students will do in their group activity. Use a variety of wedges, such as a chisel and hammer, and a plastic knife, on two very different materials, such as a brick and a stick of cold margarine. Some of the wedges will not be successful at cutting the hard materials, due to the wedge angle being too dull or the wedge material being too weak. Having two very different "rock" samples (brick and margarine) helps students understand why we need to design different types of wedges that are made from different materials, and introduces the idea of the importance of appropriate material selection.

- For the student group activity, divide the class into pairs of two students each (although groups of three work well, too).

- Direct each team of students to test their given wedges on each of their given "rock" sample materials. Allow them ~20 minutes to complete the activity.

- Instruct the students to record the performance of each wedge and "rock" sample on their worksheet, using the provided rating scale.

- As a class, conclude the activity by comparing test results among all teams and holding a class discussion. Which wedge/rock combinations were successful? Which were not? Why? How are the wedge angles and points different from each other? Which wedge had the sharpest angle? Which had the biggest cutting surface? How does this make a difference? (Possible answers: A larger cutting surface allows the user to exert more force on the object being cut.) Why do you think engineers design different types of wedges? (Possible answers: Depending upon the characteristics of the material to be cut, they might need to design stronger, but more expensive wedges to cut hard materials.) Why is material selection an important engineering job? (Possible answer: If you choose the incorrect material for your wedge, the tool will not work well and your project may not be successful.)

Vocabulary/Definitions

angle: The "sharpness" of a wedge.

design: (verb) To plan out in systematic, often graphic form. To create for a particular purpose or effect. Design a building. (noun) A well thought-out plan.

mechanical advantage: An advantage gained by using simple machines to accomplish work with less effort. Making the task easier (which means it requires less force), but may require more time or room to work (more distance, rope, etc.). For example, applying a smaller force over a longer distance to achieve the same effect as applying a large force over a small distance. The ratio of the output force exerted by a machine to the input force applied to it.

quarry: A pit from which rock or stone is removed from the ground.

simple machine: A machine with few or no moving parts that is used to make work easier (provides a mechanical advantage). For example, a wedge, wheel and axle, lever, inclined plane, screw, or pulley.

tool: A device used to do work.

wedge: A simple machine that forces materials apart. Used for splitting, tightening, securing or levering. It is thick at one end and tapered to a thin edge at the other.

work: Force on an object multiplied by the distance it moves. W = F x d (force multiplied by distance).

Assessment

Pre-Activity Assessment

Know / Want to Know / Learn (KWL) Chart: Before the activity, ask students to write down in the top left corner of a piece of paper (or as a group on the board) under the title, Know, all the things they know about wedges. Next, in the top right corner under the title, Want to Know, ask students to write down anything they want to know about wedges. After the activity, ask students to list in the bottom half of the page under the title, Learned, all of the things that they have learned about wedges.

Activity Embedded Assessment

Material Selection Discussion: After the teacher demonstration, take a few minutes to lead a class discussion about the strengths and weaknesses of each type of wedge material. Write these on the board. This will get the students thinking about material selection before they start their group activity.

Worksheet: Have the students record their test results on The Wedge Worksheet; review their answers to gauge their mastery of the subject.

Post-Activity Assessment

KWL Chart: Finish the remaining section of the KWL Chart as described in the Pre-Activity Assessment section. After the activity, ask students to list in the bottom half of the page under the title, Learned, all of the things that they have learned about wedges. Ask students to name a few items and list them.

Engineering Recommendations: List two or three rock types on the board while the students are finishing the activity and the worksheet questions. Have the students discuss within their groups recommendations for a wedge design to cut through each of the rocks listed. They should suggest what material the wedge should be made from, and how sharp the wedge needs to be.

Class Discussion: Have the students participate in a concluding class discussion about their group test results and answers to the worksheet questions. Which wedge/rock combinations worked? Which did not? Why? How are the wedge angles and points different from each other? Which wedge had the sharpest angle? Which had the biggest cutting surface? How does this make a difference? Why do you think engineers design different types of wedges? Why is material selection an important engineering job?

Safety Issues

- While safety protection is not required, students should be aware that wedges have sharp edges so safety precautions need to be taken when handling them.

- Students should not be given metal wedges such a nails.

Troubleshooting Tips

To keep the desks clean and for ease of clean-up, set materials on a tray, paper or cardboard.

Make wedges by sanding the edge of a piece of material such as plastic or wood to create a tapered edge.

Using foam can be useful as an example of a material that does not work well in a wedge application.

Alternate activity setup: If a limited number of supplies are available, each group could work with only one wedge and one material. At the end, each group could share what they learned with the entire class. Alternatively, group sizes of three work fine for this activity.

If the students have a hard time understanding how a wedge works, present a variety of pictures of a wedge in action.

Activity Extensions

Compile the class worksheet data on the board to provide some nice extension possibilities, discussion, math exercises (averages), graphing, etc. Discuss success in terms of the choice of material or wedge.

Have students explore material properties and material use. Engage the class in a discussion on how the pyramid stones had been shaped and what materials were used (metals, harder stones, etc).

Have the students design their own wedge to serve a specific purpose. For example, ask them to design a wedge that moves snow or splits air (such as an airplane wing). This wedge does not have to be sharp because air is not "hard." How is a zipper considered a wedge?

If possible, take a field trip to a local quarry to see how wedges are used and help students better understand the scale of materials that are extracted from a rock quarry.

Activity Scaling

- For lower grades, a pencil can be used as a wedge to simplify the amount of materials. In this version, students learn how just one material cuts through various types of other materials, such as marshmallows, wax, sandwiches, etc. Have them rate the success of the pencil in cutting each material so they come to understand how a wedge can be used to split materials.

- For higher grades, assign students the task of extracting 4 cubic cm of each material using the provided wedges.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn how simple machines, including wedges, were used in building both ancient pyramids and present-day skyscrapers. In a hands-on activity, students test a variety of wedges on different materials (wax, soap, clay, foam).

Students are introduced to the six types of simple machines — the wedge, wheel and axle, lever, inclined plane, screw, and pulley — in the context of the construction of a pyramid, gaining high-level insights into tools that have been used since ancient times and are still in use today.

Refreshed with an understanding of the six simple machines; screw, wedge, pully, incline plane, wheel and axle, and lever, student groups receive materials and an allotted amount of time to act as mechanical engineers to design and create machines that can complete specified tasks.

This lesson introduces students to three of the six simple machines used by many engineers. These machines include the inclined plane, the wedge and the screw.

References

Bochnacki, Andrzeh. 2005. O Piramidach Inaczeh. Andrzej Bochnacki (Polish engineer). Accessed January 18, 2006. (An excellent animation shows how heavy stone blocks might have been systematically moved up an incline plane using many human-powered wedges. Click on Site Map, then click on Transport on the Ramp.) http://www.swbochnacki.com/

Construction of the Great Pyramid, Construction Theories. World-Mysteries.com. Accessed January 18, 2006. http://www.world-mysteries.com/mpl_2_1.htm#Machines

Nature & Science: Geologic Resources, Abandoned Mineral Land: Nature & Science. Updated October 19, 2003. National Park Service, U.S. Department of the Interior. January 18, 2006. http://www2.nature.nps.gov/geology/aml/

Copyright

© 2005 by Regents of the University of Colorado.Contributors

Lindsey Wright; Lawrence E. Carlson; Jacquelyn Sullivan; Malinda Schaefer Zarske; Denise Carlson, with design input from the students in the spring 2005 K-12 Engineering Outreach Corps course.Supporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under a grant from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education, and National Science Foundation GK-12 grant no 0338326. However, these contents do not necessarily represent the policies of the Department of Education or National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: August 14, 2020

User Comments & Tips