Summary

Students experiment with various ways to naturally dye materials using sources found in nature—roots, leaves, seeds, spices, etc.—as well as the method of extracting dyes. Then they analyze various materials using statistical methods and tackle an engineering design challenge—to find dyes that best suit the needs of a startup sustainable clothing company.Engineering Connection

Acting like chemical engineers, students apply principles of engineering, chemistry, biology, physics, and mathematics to solve problems that that involve the production or use of chemicals, fuel, drugs, food, and many other products. They design processes and equipment for large-scale manufacturing, plan and test methods of manufacturing products and treating byproducts, and supervise production.

In addition, students play the role of dye chemists; they research and create new dye colors, develop new methods for creating or extracting dyes, iterate on previous methods for modifying dyes to formulate products that have longer-lasting effects and are less toxic. They also focus specifically on design methods based on how the dyes are intended to be used for specific end products.

Learning Objectives

After this activity, students should be able to:

- Identify solutes and solvents in a solution.

- Calculate the concentration of a solution.

- Use technology to collect data.

- Analyze real data and create dot plots.

- Employ statistics to analyze two or more different data sets.

- Communicate quantitative and technical information using words.

- Use visual art to solve a problem.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

Common Core State Standards - Math

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Make inferences and justify conclusions from sample surveys, experiments, and observational studies

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Summarize, represent, and interpret data on a single count or measurement variable

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data with plots on the real number line (dot plots, histograms, and box plots).

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

Ohio - Math

-

Reason abstractly and quantitatively.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Make inferences and justify conclusions from sample surveys, experiments, and observational studies.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Summarize, represent, and interpret data on a single count or measurement variable.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data with plots on the real number line (dot plots, histograms, and box plots) in the context of real-world applications using the GAISE model.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Ohio - Science

-

Use technology and mathematics to improve investigations and communications

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Solubility

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group needs:

- Student Packet

- Serial Dilution Experiment Sheet

- Dye Technical Data Sheet

- 5 clear glass containers

- graduated cylinder

- 500 ml water

- food coloring

- 5 Alka-Seltzer™ tablets

- stopwatch

- 500 ml distilled white vinegar

- access to a computer, for research on Day 1

- tablet with camera and ColorAssist (for iOS) Color Grab (for Android) or similar app; see Additional Multimedia Support

- silicone lab gloves (optional, but dyes have the potential to get messy)

To share with the entire class:

- capability to show the class Dyeing to Design PowerPoint® Presentation on Day 1

- edible materials, five to seven items each; for best results, the more crushed/ground/chopped the material is prior to placing in the solvent, the more dye will be extracted; examples: red cabbage, beets, spinach, berries, onion peel (red & yellow), red plum, spices (turmeric, paprika, chili powder, cloves, etc.); check for individuals in the class who may have food allergies prior to sourcing materials

- color swatches; to serve as a baseline for your dye colors based on the edible materials you choose; available for free at most home improvement stores

- solvents: the higher the ratio of material to solvent, the greater the color intensity; the longer the materials are in the solvent, the greater the color intensity; measurements are approximate, but teachers should judge based on their class and group size.

- water (500 ml): needs to be heated, and the longer the water and source materials are heated together the more intense the color for that concentration

- alcohol (500 ml): should not need to be heated; works well for materials that may have a color change when heated; works quickly and is observable; if the source materials are observed to have the majority of color removed, the materials can be replaced with fresh material to intensify the concentration of the dye

- vinegar: (500 ml): does not need to be heated; very little difference is observed between heating and not heating; useful for source materials that experience a color change based on pH.

- acetone: (500 ml): should not be heated; requires glass for dye extraction as the acetone breaks down plastics; useful with extracting color from spices

- application materials.

- fabric/fiber: 100% cotton works best such as old t-shirts, sheets, towels, etc; can be cut up in small 4in x 4in squares and used; cotton, wool, silk, or bamboo yarns can also be used and the greater the percentage of the natural content the more dye is absorbed; heating the fabric/fiber in the dye and then allowing the fabric to remain in the dye overnight results in more intense colors; fabric should be rinsed using cold water; if the dye is from a source that is pH responsive, make sure the fabric is dry before interacting with materials of opposite pH

- paper: different types of paper result in different colors; dyes can be painted on, just like water colors; water color paper absorbs the dye quickly compared to regular copier paper; dyes from sources that are pH responsive will change based on the paper, especially noted on acid-free paper

- wood: use small wood samples or Popsicle sticks; the dye can be applied with paintbrushes

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uod-2265-dyeing-design-dilution-concentration-solution] to print or download.Pre-Req Knowledge

Students should be able to:

- Recognize a solvent and solution.

- Calculate a percentage (for concentration).

Introduction/Motivation

Chemical engineers are engaged in a wide variety of industries, from the production of synthetic materials to the enhancement of consumer products. In fact, the chemical business is so large that sales by the top 50 companies in the world in 2017 totaled $851 billion. (Yes, that’s billon with a b!) Even though business is booming, chemical companies face a new challenge today. Many consumers, empowered with knowledge and access to research, demand products that are sustainable and environmentally-friendly. Gone are the days when consumers take products at face value. Instead, they demand to know the composition of products, particularly in the realm of textiles and clothing. That’s why a team of chemical engineers at a startup clothing company is taking advantage of this desire for sustainable clothing made with non-toxic materials and dyes. However, they need your help!

The company’s founders are eager to release a new line of clothing for children and babies that speaks to this new demand. They have chosen several sustainable fabrics to use for this new product line, but they need your chemical engineering assistance to find safe dyes that also provide vibrant colors. They are asking your team of chemical engineers to create a design pitch showing at least two different materials colored to match with their fabric sample.

To help with reproduction of colors on a larger scale for the room, they request the colorant (solute), solvent, concentration, and other physical and chemical properties of the dyes. Your challenge is to work as if you are chemical engineers to collaboratively use natural materials to create a dye that mimics the client's desired color such as the RGB value.

Procedure

Background

Review the Dyeing to Design PowerPoint Presentation to give students a background on the challenge, the engineering design process, solvent, solute, solution, and concentration. This also provides an explanation of the roles within groups.

Before the Activity

Day 1: Determine how to form teams. Have computers available for research. Make copies of the Pre-Post Quiz, one per student, and Student Packet, one per group. Prepare to show the class the Dying to Design Presentation.

Day 2: Set up Serial Dilution Experiment materials. Make copies of the Serial Dilution Experiment Sheet. Gather color sample(s), such as color swatches from the paint section of home improvement stores.

Days 3 and 4: Set up student stations:

- Station 1: source materials for dyes

- Station 2: various solvents (water, alcohol, vinegar, acetone)

- Station 3: applications (fabric, wood, paper)

- Ensure each group has access to the ColorAssist app (or similar color analyzation app on a tablet or phone with a camera).

- Make copies of the Dye Technical Data Sheet, one per group.

Day 5: Make copies of the Pre-Post Quiz and the Rubrics and Feedback Forms, one each per student.

With the Students

Day 1

- Decide teams and roles. Suggested roles are provided in the Dyeing to Design Presentation.

- Distribute and evaluate the Pre/Post-Quiz. Use this to help guide your conversations, instruction, and to measure growth during the course of the activity.

- Using the slides, propose the situation and discuss possible situations. Distribute the Student Packet, then use the chart on the first page to guide the conversation.

- Have students read through the steps of the engineering design process (EDP) and give a possible example.

- Have students research possible answers to their own questions. (EDP steps 1 and 2 on the student packet.)

Day 2

- Distribute the Serial Dilution Experiment Sheet and have students perform the serial dilution experiment.

- Hand out an example color swatch that you want students to achieve. Either give each team the same color or give each group a different color.

- Have students develop a possible solution to the problem (EDP Step 3 in the Student Packet.)

Days 3 and 4

- Distribute the Dye Technical Data Sheet, one per group.

- Have students test their ideas using stations 1-3. Be sure students try various methods of extraction and different materials so they obtain a wide range of results.

- Make sure students record each step on the Dye Technical Data Sheet.

- Have students test the RGB values of their desired material using the ColorAssist app. (Use the RGB Comparison Example for instructional on how to record data; students record data in EDP Step 4 in the Student Packet.)

- Then have students measure the RGB values of their materials using the ColorAssist app.

- Have students decide on the best possible solutions using their information by comparing the RGB values of their own materials and those desired. (Students complete EDP Step 4 in the Student Packet.)

Note: See Activity Extension; students may spend more time graphing their RGB data. Consider having all groups contribute to a shared document so that teams have a wider list of materials from which to choose for their possible solutions

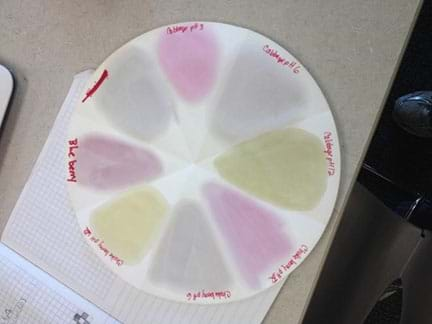

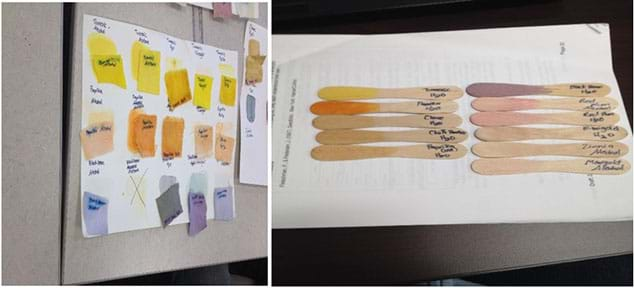

- Have students test up to four possible solutions; Figures 1 and 2 show ways that teams might organize their testing results for their pitch presentations. (Students complete EDP Steps 5 & 6 in the Student Packet.)

- Remind students that, like engineers, they are to consider possible redesigns (and test if time/materials allow). (EDP Step 7 in the Student Packet.)

Day 5

- Re-administer the Pre/Post-Quiz.

- Have student groups present on their findings. Grade them using the teacher rubrics and group feedback form in the Rubrics and Feedback Forms.

Vocabulary/Definitions

acetone: A naturally occurring colorless, flammable liquid that used as a solvent for cleaning and other applications.

concentration: The abundance of a constituent divided by the total volume of a mixture; diluted solutions have low concentrations while “concentrated” solutions contain less solvent, such as water.

solute: A substance dissolved in another substance.

solution: A homogenous mixture composed of two or more substances; for example, a saline water solution is made by adding table salt to water.

solvent: A material capable of dissolving another substance.

Assessment

Pre-Activity Assessment

Pre-Quiz: Administer the Pre/Post-Quiz. Have students work on their own as they complete the test. Review their answers to gauge their mastery of the pre-requisite concepts.

Activity Embedded Assessment

Student Packet: As students work on this activity, have them use and complete the Student Packet. Ensure that each student writes down information for each section of the packet, even if they split up researching and data collection among group members.

Post-Activity Assessment

Rubrics: For expectations and grading details for the design proposal and technical data sheet, have students and the teacher refer to the Rubrics and Feedback Form.

Post-Quiz: Administer the Pre/Post-Quiz again. Compare students’ pre- and post-scores to determine their knowledge gains from conducting the activity.

Pitch Presentation: Have groups present their results as though they are talking to the family who asked them to design the nursery. As other teams present, students complete the Group Feedback Form (see the Rubrics and Feedback Form).

Safety Issues

- Be conscious of food allergies when deciding on test materials.

- Hot water could be a possible solute so have students use appropriate safety measures.

- Take the necessary lab safety cautions when using acetone as a solvent.

Activity Extensions

- Spend more time teaching students how to graph the RGB values as a way of comparison. Have each group graph their individual data, or have the class input data into one shared spreadsheet.

- After the pitch presentations, have groups discuss their redesign ideas as a class. Remind students that, just like engineers, collaborating often generates more and new ideas and options for improving their designs.

Activity Scaling

- For lower grades, use fewer dye and testing materials. Have the teacher gather RGB data for each group.

- For higher grades, have students complete market research on natural dyes and develop a product that uses natural dyes.

Additional Multimedia Support

A number of applications exist to identify colors. ColorAssist Lite is available for free for Apple devices, and a 99¢ version is available with full features. Color Grab is a free app for the Android platform. The applications do not give a 100% perfect answer, but are useful to identify patterns and relationships with the RGB values.

ColorAssist Lite: https://itunes.apple.com/us/app/colorassist-lite/id495034867?mt=8

ColorAssist (paid): https://itunes.apple.com/us/app/colorassist/id496585813?mt=8

Color Grab: https://play.google.com/store/apps/details?id=com.loomatix.colorgrab&hl=en_US

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn and discuss the advantages and disadvantages of renewable and non-renewable energy sources. They also learn about our nation's electric power grid and what it means for a residential home to be "off the grid."

References

Tullo, Alexander. “C&EN’s Global Top 50 chemical companies.” Published July 30, 2018. Chemical and Engineering News. Accessed October 15, 2018. https://cen.acs.org/business/finance/CENs-Global-Top-50-chemical/96/i31

Copyright

© 2018 by Regents of the University of Colorado; original © 2016 Central State University, University of Dayton, and Wright State UniversityContributors

Craig George; Amanda Grear; Carly Monfort; Brett DoudicanSupporting Program

Collaborative RET with Central State University, University of Dayton, and Wright State UniversityAcknowledgements

This material is based upon work supported by the National Science Foundation under grant no. EEC 1405869—a collaborative Research Experience for Teachers Program titled, “Inspiring Next Generation High-Skilled Workforce in Advanced Manufacturing and Materials,” at the University of Dayton, Central State University and Wright State University in Ohio. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: May 13, 2021

User Comments & Tips