Quick Look

Grade Level: 9 (9-12)

Time Required: 45 minutes

Expendable Cost/Group: US $0.00

Group Size: 3

Activity Dependency: None

Subject Areas: Biology, Physical Science, Physics

NGSS Performance Expectations:

| HS-PS3-2 |

Summary

Understanding the concepts of conduction, convection and radiation help engineers design and build systems that employ the process of heat transfer. In this activity, students use a hair dryer, hot plate and a heat lamp to show the three types of heat transfer and how these processes can be used in agricultural engineering applications. They compare the time it takes for each process and, as they learn about these processes, students delve deeper into why there are time differences for each.Engineering Connection

Since ancient times, people have been preserving food using solar energy by the process of heat transfer using solar dryers. Designs of different solar dryers have improved from the simple hanging of food to some involving some sort of automation. All three types of heat transfer, conduction, convection, and radiation are observed in solar dryers and these processes are used to engineer efficiency within solar dryer designs.

Solar drying is considered to be a simultaneous application of heat and the removal of moisture from foods which is an important process for the future of food security and sustainability. Solar drying is a method used in the food industry and in agricultural engineering as a sustainable food processing technology that minimizes waste while complying with extremely rigorous food safety challenges.

Solar dryers are used to improve the quality of the product and to reduce the drying time compared to drying products by direct sunlight. There are many types and applications of solar dryers to dry different types of agricultural products such as cereals, fruits, vegetables, meat, fish, and aromatic plants. These applications have been, and continue to be, improved by many engineers to increase the drying efficiency and improve the final quality of the dried products.

Heat transfer is a specific concept in engineering. It deals with the impact of conduction, convection, and/or radiation in specific applications. Thermal engineers can help product engineers and designers optimize the thermal energy efficiency of their device or system.

Learning Objectives

After this activity, students should be able to:

- Define conduction, convection and radiation.

- Describe at the molecular level how heat is transferred by conduction, convection and radiation.

- Explain the time differences on each process as they transfer heat from a source to an object or a substance.

- Show how conduction, convection and radiation is applied in a solar dryer and give examples for each process.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-PS3-2. Develop and use models to illustrate that energy at the macroscopic scale can be accounted for as either motions of particles or energy stored in fields. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop and use a model based on evidence to illustrate the relationships between systems or between components of a system. Alignment agreement: | Energy is a quantitative property of a system that depends on the motion and interactions of matter and radiation within that system. That there is a single quantity called energy is due to the fact that a system's total energy is conserved, even as, within the system, energy is continually transferred from one object to another and between its various possible forms. Alignment agreement: At the macroscopic scale, energy manifests itself in multiple ways, such as in motion, sound, light, and thermal energy.Alignment agreement: These relationships are better understood at the microscopic scale, at which all of the different manifestations of energy can be modeled as a combination of energy associated with the motion of particles and energy associated with the configuration (relative position of the particles). In some cases the relative position energy can be thought of as stored in fields (which mediate interactions between particles). This last concept includes radiation, a phenomenon in which energy stored in fields moves across space.Alignment agreement: | Energy cannot be created or destroyed—it only moves between one place and another place, between objects and/or fields, or between systems. Alignment agreement: |

State Standards

Texas - Science

-

investigate and demonstrate the movement of thermal energy through solids, liquids, and gases by convection, conduction, and radiation such as in weather, living, and mechanical systems;

(Grades

9 -

10)

More Details

Do you agree with this alignment?

-

contrast and give examples of different processes of thermal energy transfer, including conduction, convection, and radiation; and

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each station needs:

An infrared thermometer

Station 1 – Conduction:

- hot plate

- cup of water

- timer dropper or pipette

Station 2 – Convection:

- hair dryer

- cup of water

- petri dish covered with aluminum foil or small ceramic or metal plate that can hold a drop of water

Station 3 – Radiation:

- heat lamp (about 200 to 300 W)

- cup of water

- dropper or pipette

- petri dish with aluminum foil

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uoh-2785-heat-transfer-solar-dryers-activity] to print or download.Pre-Req Knowledge

- An understanding of basic chemistry, including definitions for molecules and particles

- An understanding of the concept of heat

Introduction/Motivation

What dried fruit or food have you eaten or tried? Let’s take a look at some example fruit and state the differences between them. Here is a dried piece of [insert name of fruit here] and here is an example of a normal piece of the same fruit.

What is the difference between a dried fruit/food and the real thing? How does a normal piece of fruit turn into a dried one? What was removed/what was done to the normal fruit for it to become dried. What do you think was the process used? What energy was involved in the process? Were there any scientific or engineering concepts that were used to help this process?

In this activity, we’ll be exploring one key process – heat transfer – to understand how the concepts of conduction, convection and radiation work in a unique engineering application. Let’s get started!

Procedure

Background

(Have students read the Heat Transfer Article and fill out the Intro to Heat Transfer Worksheet. Alternatively, go over the background with the students.)

Solar drying technology was invented in the 1950’s as a solution to a common issue related to the scaling of commercial farms, since commercial operations could not rely on open sun drying alone. Solar drying technology was given even more attention later following the oil crisis in 1973, when nations became interested in in finding an alternative system with a sustainable energy source for grain and fish drying.

Solar drying also became a popular process in agricultural applications in tropical countries like Asia and sub-Saharan Africa, where the solar drying potential is higher.

More advanced solar drying systems are being developed through time and today based on the commodity nature, location, cost, and other factors that are of concern we can choose what is best for our purpose.

Here’s a brief introduction to several basic types of solar dryers.

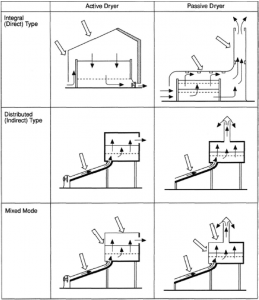

In active dryers, airflow inside the dryer is made by a fan powered with electricity while passive dryers use natural convection to create airflow. Further, dryers are categorized into 3 main types namely Direct, Indirect, and Mixed-mode.

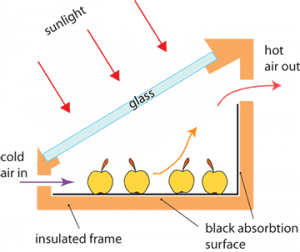

Direct Type Dryers

Direct type dryers are like a cabinet with a compartment and a glass roof. Solar rays directly fall onto the commodity (the crop) through the glass and use the greenhouse effect to create heat. The airflow carries away the moisture as shown below. Tunnel, greenhouse, and cabinet-type dryers fall into this category.

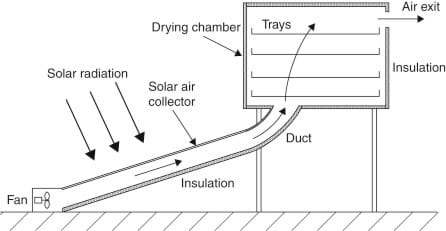

Indirect Type Dryers

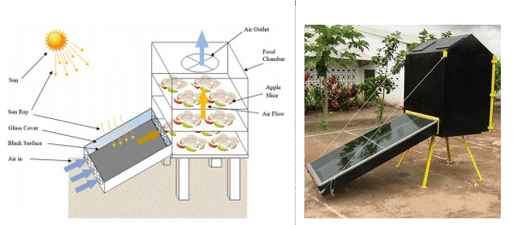

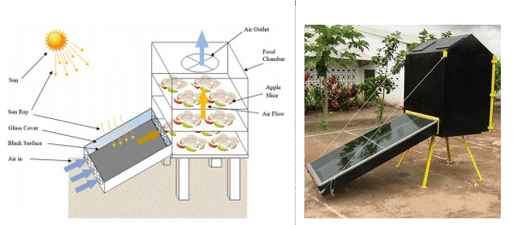

Indirect type solar dryers have separate chambers for drying and heating airflow. In here there’s no direct contact between solar rays and the crop as shown in the figure below. Airflow entering from solar collector gets heated up and carries away the moisture from drying chamber.

Mixed-mode Dryers

Mixed-mode dryers are a combination of above two types. The structure is similar to an indirect dryer but the drying chamber is made of transparent material such that the solar collector and drying chamber both get heated up by the greenhouse effect.

[Have students fill out the Solar Dryer Heat Transfer Worksheet as an assessment after the background section.]

Before the activity

Set up each station with its respective materials. Hand out the Heat Transfer Lab Worksheet to be completed during the activity and the Heat Transfer Comparison Worksheet to be completed after the activity.

With the Students

Station 1:

- Plug the hot plate and adjust the temperature knob to medium.

- Using the thermometer, measure the temperature of the hot plate.

- Set the timer and place a drop of water using the dropper or pipette directly on the hot plate.

- Measure the time until the drop of water is completely dried out.

- Adjust the temperature knob of the hot plate to the maximum setting.

- Repeat steps 2 and 3.

- Record the time in the data section.

Station 2:

- Plug the hair dryer.

- Using the thermometer, measure the temperature of the petri dish.

- Set the timer and place a drop of water on the petri dish and cover it with foil.

- Turn on the dryer and set it to maximum.

- Point the dryer directly on the top of the foil

- Measure the time until the water is completely dried out.

- Record the time in the data section.

- Record the time.

Station 3:

- Plug and turn the heat lamp on.

- Using the thermometer, measure the temperature of the hot plate.

- Set the timer and place a drop of water on the petri dish.

- Point the heat lamp directly on the drop of water at about a 3 cm away from the water.

- Measure the time until the drop of water is completely dried out.

- Record the time in the data section.

Vocabulary/Definitions

conduction: Heat transfer that involves contact, applies to solids.

convection: Heat transfer by moving particles carrying heat, applies to liquids and gas.

heat transfer: A form of energy transfer through conduction, convection, and/or radiation. Heat transfer occurs any time there is a temperature difference between two objects and occurs in the direction of decreasing temperature, meaning from a hot object to a cold object.

solar dryer: A device that use solar energy to dry substances, especially food. Solar dryers use the heat from sun to remove the moisture content of food.

Assessment

Pre-Activity Assessment

The teacher will ask what dried fruit or food they have eaten or tried. If the budget permits, the teacher can bring some dried food for the students to try, like dried mango (or another dried fruit) and a normal mango. It can also be done by showing a picture of a dried mango and a normal mango fruit and the teacher can ask what the difference between the two. Then the deeper questions can be asked – how does a normal mango turn into a dried mango? What was removed/what was done to the normal mango for it to become dried mango. What does the students think was the process used? What energy was involved in the process? This will lead to a robust discussion and using leading questions like, how do farmers dry their food?

After the discussion and the background section, have students complete the Introduction to Heat Transfer Worksheet and the Solar Dryer Heat Transfer Worksheet.

Activity Embedded (Formative) Assessment

Students complete the Heat Transfer Lab Sheet.

Post-Activity (Summative) Assessment

Students complete the Heat Transfer Comparison Worksheet.

Investigating Questions

The teacher will show a picture of a conventional food solar dryer.

and include the following questions:

How do farmers preserve food by using heat form the sun? (Answer: Produce can be dried by using solar radiation by removing water/moisture from the food. Solar (sun) drying is cheap and designs have progressed to even some applied automation in the drying process.)

How are convection, conduction and radiation shown or applied in solar dryers? Show examples. (Answer: Radiation – direct sunlight provides radiation to the moving air in the solar air collector. If the drying chamber clear material, the radiation from the sun also adds to the heat inside the chamber. Convection – there an air flow that transfer heat caused by the fan that moves heat up to the drying chambers. Inside the drying chambers there is also some air flow that transfers heat. Conduction – The trays are directly touching the food and are also heated by either convection or radiation and they transfer the heat they have by conduction to the food.)

Safety Issues

- Use goggles for eye protection

- Use gloves or tongs when picking up hot objects

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn about the definition of heat as a form of energy and how it exists in everyday life. They learn about the three types of heat transfer—conduction, convection and radiation—as well as the connection between heat and insulation.

Students learn about the nature of thermal energy, temperature and how materials store thermal energy. They discuss the difference between conduction, convection and radiation of thermal energy, and complete activities in which they investigate the difference between temperature, thermal energy and ...

Students learn the scientific concepts of temperature, heat and the transfer of heat through conduction, convection and radiation, which are illustrated by comparison to magical spells found in the Harry Potter books.

Students explore heat transfer and energy efficiency using the context of energy efficient houses. They gain a solid understanding of the three types of heat transfer: radiation, convection and conduction, which are explained in detail and related to the real world.

Copyright

© 2023 by Regents of the University of Colorado; original © 2022 University of HoustonContributors

Roberto DimaliwatSupporting Program

University of Houston College of Technology RET Program Summer 2022Acknowledgements

This curriculum was developed under National Science Foundation RET grant no. 1855147— Research Experience for Teachers in Advanced Design and Manufacturing at the University of Houston. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: September 27, 2023

User Comments & Tips