Quick Look

Grade Level: 9 (9-10)

Time Required: 4 hours 30 minutes

(three 90-minute sessions)

Expendable Cost/Group: US $0.00

Group Size: 3

Activity Dependency: None

Subject Areas: Data Analysis and Probability, Measurement, Number and Operations, Problem Solving, Reasoning and Proof, Science and Technology

NGSS Performance Expectations:

| HS-ETS1-3 |

Summary

Students become “efficiency experts” who have been contracted by an auto manufacturer. They are presented with plans for three car models (made from plastic building bricks) the company currently makes. The current designs are selling well but are not as profitable as the company would like, because they require more building materials (plastic bricks) and take more time to build than would be ideal. After conducting a simulation of the company’s current mass production system, the “efficiency experts” are asked to propose modifications to the current system (e.g., vehicle design, assembly line layout, and labor allocation) that will allow the company to make more cars for a lower price, while remaining within specific safety and efficiency guidelines required by law. The “efficiency experts” then implement their redesigned system and compare building time and cost of the revised system to the original one. Finally, the experts prepare a presentation for the auto manufacturer’s executives during which they report their proposed modifications, citing specific examples of cost and time that was saved between the original production process and the revised one.Engineering Connection

Industrial engineers focus on making systems, processes, and organizations more efficient. They study how people, machines, materials, and energy work together, then redesign processes to save time, cut costs, and improve safety and quality. Instead of just building things, industrial engineers look at the “big picture” of how products are made, or services are delivered, finding ways to do more with less while still meeting important standards.

Learning Objectives

After this activity, students should be able to:

- Analyze a mass production system to identify inefficiencies related to cost and time, reflecting real world manufacturing challenges.

- Apply the engineering design process by planning, testing, and refining modifications to improve assembly line performance, supported by data and performance comparisons.

- Demonstrate collaboration, problem-solving, and communication skills by working in teams to develop a final presentation that outlines design decisions, test results, and a recommended implementation plan.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

Common Core State Standards - Math

-

Choose a level of accuracy appropriate to limitations on measurement when reporting quantities.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Develop a plan that incorporates knowledge from science, mathematics, and other disciplines to design or improve a technological product or system.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Select resources that involve tradeoffs between competing values, such as availability, cost, desirability, and waste, while solving problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Implement quality control as a planned process to ensure that a product, service, or system meets established criteria.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Document trade-offs in the technology and engineering design process to produce the optimal design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Apply principles of human-centered design.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

Each group (recommended 8-10 students each) needs:

- (optional) Teach Engineering Engineering Design Process Handout

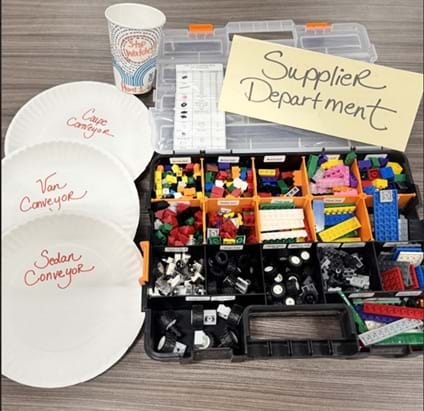

- 1 plastic brick kit, composed of the parts listed in the Plastic Brick Kit Components Sheet (also see this Amazon list for ordering brick parts)

- 1 Safety & Efficiency Guidelines Sheet

- 1 Graphic Assembly Guide

- 1 Huddle Meeting Handout

- 1 Assembly Specification Slips

- access to Weight & Cost Calculation Sheet

- access to Mass Production Efficiency Data Spreadsheet

- 1 calculator

- 1 stopwatch

- 20 small cups

- 1 Sharpie (to write on cups)

- 20 paper plates

- 1 device to take photos and document prototypes (e.g., cell phone)

- 1 laptop or computer to work on spreadsheets

For the entire class:

- 1 laptop or computer with projector to display instructions, videos, and time/timer

- designated testing area with materials for ramp and drop tests (Note: The teachers who contributed to this activity created relatively elaborate versions. The associated activity images do not reflect how these materials must appear. Testing areas can be made from a wide variety of sloped and elevated surfaces, depending on classroom setting and materials available.) See Teacher’s Quality Testing Equipment Presentation

- Mass Production Presentation teacher script

- cardstock for Activity Station Place Cards

- (optional) Exit Slips (1 per student)

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uol-3007-fast-track-factory-mass-production-activity] to print or download.Introduction/Motivation

Welcome to the Fast Track Factory! Today we are going to take a deep dive into the revolutionary world of mass production.

First, before mass production, products were created using craft production. Who knows what craft production is? (Let students offer answers.) Craft production is a manufacturing process that relies on the skills of an individual artisan/builder/engineer to create unique, often custom, products primarily by hand or with the aid of non-automated tools.

When making cars using craft production, one artisan/builder/engineer designs and builds the product individually. But what happens when a company needs to make hundreds, thousands, or even millions of cars? Think about how cars are made in the real world. Car companies do not have one person build an entire car from scratch. Instead, they use an assembly line. One person might be responsible for installing the engine, another for the doors, and another for the tires. By working together in a system, cars can be made faster, more efficiently, and at a lower cost.

To kick off this activity, we are going to watch a short video showing the process of cars being built on an actual assembly line. As you watch, write down what you notice and what you wonder. (Play video clip of a car assembly line in action. Tip: Start at the 4-minute mark to jump straight into the assembly information.)

Let us discuss your observations. What did you notice about the speed of production? (Potential things to notice: order of car parts being built, which car part gets built first, how the workers are organized, and how long each step takes.)

What do you wonder? What questions do you have about how this process works? (Possible things to wonder: "How do they keep everything organized?" "What happens if one part of the line breaks?" "Does this save money?" "Are all cars made the same way?")

Why do you think most companies choose mass production over craft production? (Potential answers: more profit, more efficiency, more production.)

In this activity, you are going to take on engineering roles as efficiency experts for Fast Track Factory. You are going to take three of the popular vehicle models and rework the mass production system to make it faster, leaner, and more profitable. Each of you will work as part of a production team with a specific task. Your goal is to build cars that meet the safety design specs as quickly, accurately, and cheaply as possible.

Get ready to step into the world of mass production and experience the power of innovation firsthand!

Procedure

Background

Mass production is a manufacturing process used to produce large quantities of standardized products quickly and efficiently. In this process, the production tasks are divided into smaller, repetitive tasks, with each task being completed by a specific station or worker. This contrasts with craft production, where products are made individually by one person or a small team from start to finish. Mass production is a hallmark of modern industry and has been instrumental in making goods more affordable and accessible.

The key concept of mass production is specialization, during which each worker or machine performs a specific task repeatedly, increasing speed and efficiency while maintaining quality. One of the earliest examples of mass production was introduced by Henry Ford in the assembly line for automobiles. By dividing car manufacturing into a series of smaller tasks and moving the cars along a production line, Ford’s factories were able to produce cars at unprecedented speed and with consistent quality.

In this activity, students will experience the principles of mass production firsthand. Working in small teams, each student will take on a specific role in the production process:

- Design Engineers: plan and guide vehicle and assembly line designs to make sure all specifications and requirements are met.

- Sourcing Engineers: gather and manage materials needed to build the product according to specifications.

- Manufacturing Engineers (Builders): assemble the vehicles, following the design requirements.

- Quality Engineers (Testers): check the final product to make sure it works and looks the way it should.

Before the Activity

Part 1: Research/Information Gathering (Ask-Research-Imagine of the Engineering Design Process)

- (optional) Make copies of the Engineering Design Process Handout to refer to during the activities.

- Gather equipment/materials for each group: (Plastic Brick KIT Components, 20 small cups, Sharpie, 6-10 stopwatches, student devices, pencils.)

- Print copies of the Graphic Assembly Guide and Safety & Efficiency Guidelines.

- Open Mass Production Presentation (Phase 1 Section)

- Provide an electronic copy of the Weight & Cost Calculation Sheet.

- Distribute materials to each group.

Part 2: Physical Simulations (Plan-Create-Test-Improve of the Engineering Design Process)

Includes Round 1 (“Initial”), Round 2 (“Revised”), and an Optional Round 3 (“Final Revision”)

- Make additional copies if needed of the Graphic Assembly Guide and Safety & Efficiency Guidelines from Phase One.

- Print (per group) 10-20 sets of Assembly Specification Slips

- Print one set of Activity Station Place Cards on cardstock.

- Provide each group with a device and a copy of the Mass Production Efficiency Data Spreadsheet.

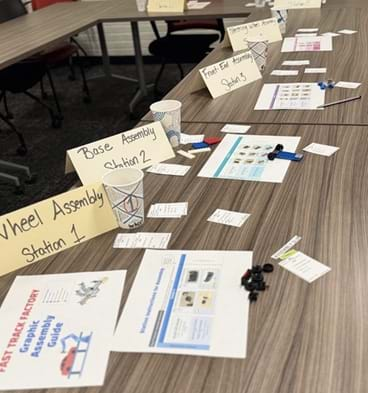

- Set up Required Stations:

- Use Activity Station Place Cards to set up station locations: Supply Area, Building Station 1,2,3,4,5, and 6, and Testing Area.

- The Supply Area requires the cardstock place card, plastic brick kit (missing the parts loaded into the bins during Phase One), and 1 complete set of Assembly Specification Slips (pages 1-3 for Round 1: initial simulation).

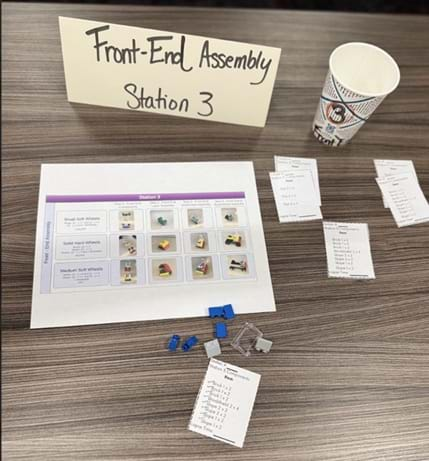

- The Building Stations 1-6 each require the cardstock activity place cards, 3 paper plates, a stopwatch, and the appropriate part of the Graphic Assembly Guide for their station, and supply bin (paper cup “stocked” during the previous activity) for the appropriate part of the car.

- The Testing Area requires labeled placards cardstock, a sloped surface that acts as the test ramp, and an elevated surface that acts as the drop test, as well as Quality Testing strips cut out from the bottom of the Assembly Specification Slips.

- Set up the ramp and drop test areas.

- Open the Mass Production Presentation (Phase 2 Section).

- Distribute materials to each group.

- (Optional) Exit Slips (May be used at any time during the 2nd phase).

Part 3: Efficiency Analysis (Evaluate-Improve of the Engineering Design Process)

- Print a copy of the Huddle Meeting Handout for each group.

- Distribute copies to each group.

- Open the Mass Production Presentation (Phase 3 Section).

During the Activity

Day 1

Part 1: Mass Production Design Phase (90 minutes)

- Display the Mass Production Presentation, which will be used to walk students through the entire activity.

- Use the Mass Production Presentation (Phase 1) Slide 4 to introduce students to the scenario: they are being “hired” by an automotive company to help them enhance efficiency and profitability. (Note: This slide sets the stage by explaining that each student team is acting as a group of efficiency experts, hired by the company to improve the production of three popular vehicle models. Their mission: redesign the mass production system to make it faster, more efficient, and more profitable, while still meeting strict safety and efficiency regulations.)

- Use Slide 5 to explain background information on the basic concepts behind mass production.

- Use Slide 6 to introduce students to major concepts involving assembly lines, with the YouTube video (9:09) embedded. (Teacher Tip: The entire video offers a brief, yet comprehensive, overview of the shift from craft to mass production throughout history. If time is a limiting factor, start at the 4-minute mark to jump straight into the assembly line information.)

- Use Slides 7–8 to introduce the key concepts of the engineering design process and different engineering roles.

- Use Slide 9 to transition students from the building background stage back to the scenario, beginning with showing them the current design for three vehicle models: coupe, sedan, and van.

- Give each group a printed Graphic Assembly Guide.

- Use Slide 10 to show students the Graphic Assembly Guide, a reference that illustrates how to assemble each vehicle.

- Use Slide 11 and allow students time (suggested ~20 minutes) to familiarize themselves with the specifications outlined in the Graphic Assembly Guide, and build the company prototypes.

- After students familiarize themselves with the vehicle specifications, use Slide 12 to ask them to consider potential modifications they could make to the current vehicle designs, with the goal of making them faster to build (example: more streamlined) and cheaper (example: requiring fewer parts).

- Using the same slide, introduce the Safety & Efficiency Guidelines and the Weight & Cost Calculation Sheet.

- Explain to students that state and federal laws often dictate certain characteristics of cars.

- For example, to prevent the van from flipping over, the base must be a certain size, and it must have specific tires.

- The Safety & Efficiency Guidelines list tells students the requirements for each model. Tell them that, while they have a freedom over the design, their proposed changes must meet these requirements.

- Still on Slide 12, tell students that the car company’s market research team has discovered the highest price customers are willing to pay for each vehicle, which is also listed on the Safety & Efficiency Guidelines.

- Provide a copy of the Weight & Cost Calculation Sheet to each group. This sheet provides the cost of each car part (plastic brick), and students should use it to add up the cost of building each of their revised models, so that they know how much the raw materials are to build. (If students have added correctly, their totals should match those on Slide 33.)

- Use Slide 13 to tell students they will now resume the role of efficiency experts and propose potential changes to each vehicle’s design, for greater efficiency and cost-effectiveness.

- Using Slide 13, give students 10 minutes to open a blank document (e.g., Word, Google Doc, etc.) on their laptop and record their proposed changes, including pictures.

- End the class period by asking students: “Which steps of the engineering design process did your team use most effectively during this activity, and how could those steps help improve your final vehicle designs?”

Day 2

Part 2: Mass Production Simulation (90 minutes)

- Use Slides 14-15 as a transition from vehicle design to a focus on the assembly line itself.

- Use Slide 16 to ask students to assign the engineering roles (sourcing engineers, manufacturing engineers (builders), and quality engineers (testers)), required by the current system. Ensure students understand that the design engineers played their role in the previous phase.

- Use Slide 17 to ask students to cut apart the Assembly Specification Slips on Pages 1-3.

- Use Slide 18 to show students how to use the Assembly Specification Slips to determine the parts required for each station, which should be loaded into a “supply bin” (paper cup) with enough to make at least two of each vehicle model. Tell them to make sure they label each cup with the appropriate station number, 1- 6.

- Use Slide 19 to show that the sourcing engineer should have a brick supply kit, a copy of the Graphic Assembly Guide and a full copy of the Assembly Specification Slips for each car model (coupe, sedan, and van) (Pages 1-3).

- Use Slide 20 to show that each manufacturing engineer (builder) should have the necessary parts of the Graphic Assembly Guide, a stack of Assembly Specification Slips for each car model, and a supply bin loaded with the correct materials for each car model.

- Use Slide 21 to show that the quality engineer (tester) should have a copy of the Graphic Assembly Guide, Safety & Efficiency Guidelines and (optional) prototypes to check off initial inspection. The quality station should also have the ramp and drop tests, and a stack of Quality Testing Slips (located at the bottom of Pages 1-3 from Assembly Specification Slips).

- Use Slides 22-25 to discuss the process of the assembly line, including workflow, and what each engineering position does.

- Using Slide 22, review what the manufacturing engineer/builder does:

- Confirm with the assembly line that they will build two coupes, followed by two sedans, two vans, two coupes and so forth.

- Start a stopwatch.

- Announce the start of production.

- Using Slide 23, discuss what each builder will do. Starting with builder 1, each builder will:

- Start a stopwatch.

- Fill in the vehicle number on the Assembly Specification Slip.

- Build their part of the car.

- Pass on the partially constructed vehicle to the next station (on a paper plate tray or “conveyor”).

- Stop the stopwatch and fill in the lapse time on the Assembly Specification Slip.

- Flip over completed Assembly Specification Slip, revealing a blank copy to repeat the process.

- Reset the stopwatch or hit “lap,” and begin again for the next car.

- Use Slide 24 to explain to students, once builder 6 is done, the sourcing engineer delivers the finished vehicle to the tester/quality engineer. The quality engineer then ensures that the produced car matches the specifications in the Graphic Assembly Guide, Safety & Efficiency Guidelines, and the (optional) prototype.

- If it does not match the specifications, the quality engineer should mark the “fail” box on the testing slip, and the vehicle should be returned to the builder.

- If it does match the specifications, the quality engineer should mark the vehicle as “pass,” then:

- Perform the ramp test (able to roll from top to bottom intact).

- Perform the drop test (able to survive a reasonable drop).

- All outcomes should be noted on the testing slip, then the testing slip should be flipped over to reveal a blank slip that should be used when testing the next vehicle.

- Use Slide 25 to show that:

- Once a vehicle is successfully tested, the sourcing engineer will pick up the tested vehicle, take it apart, and return all the components to the supply area.

- The station builders need to make sure they are stocked with building materials. When they realize they are out of materials, they should call out to the sourcing engineer and ask for the parts they require. The sourcing engineer should use the previously completed Assembly Specification Slip as a quick reference to retrieve the required materials from the supply area.

- Use Slide 26 as a timer (recommended ~ 30 minutes) to run Round 1 Simulation: “Initial Simulation of the Current Manufacturing Production Process.”

- Give students 30 minutes to run the first-round simulation.

- Once the allotted time for the simulation has passed, use Slide 27 to ask students to open the Mass Production Efficiency Spreadsheet. (Teacher Tip: Consider using a copy for each group as a Google Sheet, so multiple students may enter data.)

- Use Slides 28-32 to show students they should use the times they have recorded in each assembly slip to fill in the lapse time for each station under the column with the heading “Initial.” Then show them how to enter the employee number and work times. (This video link shows where to enter data, as well.)

- Use Slide 33 to tell students the raw material cost and sales price of each car, so they can enter it on the spreadsheet, on the cost profit tab.

- Use Slides 34-35 to guide students in analyzing the performance data for the simulation (Things to consider: average time spent at each building station, total number of cars built, total cost per car, total profit per car model)

- Use Slide 35 to ask students to discuss and record their thoughts about potential revisions that could be made to the vehicle design and assembly process to make it faster and cheaper. Aspects they might consider:

- Are there any unnecessary parts of the car models that can be removed or exchanged, to use fewer/less expensive parts and/or make assembly faster?

- Should the supply bins be revised at each building station to make a different supply bin for each model?

- Are there stations that should have an extra employee, to prevent bottlenecks?

- Use Slide 35 to discuss with students the role of the engineering design process in their simulation and analysis.

- Use Slide 36 to transition to the 1st revision phase.

- Use Slide 37 to tell students they should use the engineering design process to

- Make informed, strategic changes.

- Open a blank document and create their own revised copy of the Graphic Assembly Guide, with pictures.

- Update Assembly Specification Slips (Pages 4-6 provide blank or editable templates for your team)

- Reflect their changes clearly so your team can follow the new process during the next simulation.

- Use Slide 38 to tell students they should open a blank document and create their own revised copy of the Graphic Assembly Guide, with pictures. Tell them to also update Assembly Specification Slips (Pages 4-6 provide blank or editable templates for your team) to reflect the construction of the revised models.

- Tell them they should reflect on their changes clearly so their team can follow the new process during the next simulation.

- Use Slide 39 to instruct and run Round 2 Simulation: First Revision of the current manufacturing process.

- Use Slide 40 to remind students how to enter data into the Mass Production Efficiency Spreadsheet.

- Use Slides 41-42 to guide discussion about the changes in efficiency between simulations.

- Use Slide 42 to discuss reflections and the role of the engineering design process in their revisions/retest.

- Allow students to record their thoughts and conclusions in their previously developed document.

- (Optional) Round 3 Simulation: Use Slide 43 to run a second system revision or Round 3 simulation and continue to input data from the simulation in the Mass Production Efficiency Spreadsheet as it is designed to support another simulation adjustment.

Part 3: Efficiency Analysis (45 minutes)

- Use Slides 44 and 45 to transition to the analysis/presentation phase.

- Use Slide 46 to ask students to review data from their Mass Production Efficiency Spreadsheet to evaluate the production rates, costs, and profits for the coupe, sedan, and van models and propose to students specific reflection questions that address their simulation experience.

- Use Slide 47 to explain that groups will use the questions and rubric from the Huddle Meeting Handout to prepare a presentation summarizing findings and suggesting improvements.

- Based on their findings, have students prepare to present their final recommendations to the company’s executives.

- Have students submit their final efficiency analysis reports and recommendations.

Vocabulary/Definitions

assembly line: A production method in which the product is assembled step by step as it moves from station to station.

bottleneck: A slow part in the Manufacturing Production Process that holds up the whole system.

efficiency: The ability to accomplish a task with the least waste of time and effort.

engineering design process: A step-by-step method Engineers use to solve problems and create products that work well.

engineering roles: Different jobs that engineers do to help design, build, test, and improve things like machines, buildings, or systems. Each role focuses on a specific part of solving problems or creating solutions.

mass production: The process of manufacturing large quantities of standardized products, often using assembly lines.

quality control: When a company checks its products to make sure they are made correctly and work the way they are supposed to.

standardization: Making every product the same so it fits and works the right way every time.

Assessment

Pre-Activity Assessment

Class discussion: Discuss mass production.

Brainstorming: Ask students to brainstorm what challenges they might face when trying to build cars quickly and efficiently.

Activity Embedded (Formative) Assessment

Teacher Activity Monitoring: Monitor students during the simulation phase to ensure they are following the assembly line instructions.

Teacher Questions: As student finish their simulations the teacher asks each group questions like, “What are some ways your team could improve speed without sacrificing quality?”

Post-Activity (Summative) Assessment

Efficiency Analysis Reports: Students submit their efficiency analysis reports, which should include their data, (potentially) graphs, and suggestions for improving their assembly line process. The teacher evaluates the reports based on accuracy, clarity, and creativity in problem-solving.

Safety Issues

- The ramp and drop tests can be in any form aligned with available resources, but it is important for the teacher to test them first to ensure that passing the tests is indeed possible (not too high, add a cushioned bottom, etc.)

- Ensure students are careful when handling Lego™ bricks during the ramp and drop tests to avoid accidents.

Troubleshooting Tips

- If students are struggling with the assembly line process, encourage them to discuss ways they could reorganize or reassign roles for better efficiency.

- Consider locking the formulas on the spreadsheets, to prevent their removal/errors.

Activity Scaling

For Lower Grades (Grades 6-8):

- Reduce the Number of Car Models:

- Instead of designing and building three different car models (coupe, sedan, and van), reduce the number to one. This will make the activity more manageable and allow students to focus on understanding the assembly line process rather than managing multiple designs.

- Simplify the Assembly Process:

- Provide pre-made assembly line instructions instead of having students create their own. This removes some complexity and allows students to focus on executing the process. It also reduces the challenge for students who may struggle with detailed planning.

- Shorten the Simulation Time:

- Reduce the overall time for the simulation phase from 45 minutes to 30 minutes. This will shorten the activity while still allowing students to experience the assembly line process, but at a pace that is easier for younger or less experienced students.

- Reduce the Number of Tasks:

- Eliminate the requirement that students track the time at each building station, to streamline the process.

- Eliminate the Detailed Data Analysis:

- For younger students, instead of having them enter and analyze data in a spreadsheet, facilitate a simple class discussion about which group produced the most cars and why. This allows them to reflect on the concept of efficiency without requiring in-depth data analysis.

For Older/Advanced Students (Grades 9-12):

- Increase the Complexity of Car Models:

- Advanced students can design more complex car models that include additional components and features (e.g., doors, wheels, windows) requiring more detailed assembly instructions. This would introduce more stations in the assembly line and make the process more challenging.

- Incorporate Cost-Benefit Analysis:

- Have students factor in the cost of materials, time, and labor into their efficiency analysis. They can calculate the cost per car and compare it to the number of cars produced and their quality to better understand the economic impact of mass production.

- Introduce Quality Control Failures:

- Set specific conditions under which a car might fail the quality control test (e.g., if it does not meet certain design specifications or withstand the ramp/drop test). This would require students to return the product to the assembly line and redo certain steps, adding an extra layer of complexity.

- Extend the Efficiency Analysis:

- Have advanced students create graphs using Excel or Google Sheets to visually represent production data, such as cars produced per minute or the number of cars passing quality control. They can also calculate additional metrics such as average production time and cost per unit.

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!Copyright

© 2025 by Regents of the University of Colorado; original © 2024 University of LouisvilleContributors

Dr. Faisal Aqlan, University of Louisville, Department of Industrial Engineering; Dr. Liz Popelka-Brown, Seneca High School, Mathematics Teacher, Louisville, KY; Susan Hatfield, Early College & Career Center, Engineering Teacher, Elizabethtown, KYSupporting Program

Research Experience for Teachers (RET), University of Louisville, J.B. Speed School of Engineering, Department of Industrial EngineeringAcknowledgements

This curriculum was developed under National Science Foundation RET grant number 2204601. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: January 14, 2026

User Comments & Tips