Quick Look

Grade Level: 11 (10-12)

Time Required: 12 hours

(16 hours of class time over ~4-6 weeks)

Expendable Cost/Group: US $20.00 Cost is higher than a typical classroom project assignment, but this is a complex 4- to 6-week project that could be a capstone project; the expendable and non-expendable items include materials that are neither standard to a chemistry lab nor easily brought in from home.

Group Size: 3

Activity Dependency: None

Subject Areas: Chemistry, Physical Science, Physics, Problem Solving

NGSS Performance Expectations:

| HS-ETS1-2 |

| HS-ETS1-3 |

| HS-PS2-6 |

Summary

Students learn about STEM education through an engineering design challenge that focuses on improving building materials used in shantytowns. First, they consider the factors that lead to shantytown development. After researching the implications of living in shantytowns, students design, build and test cement-based concrete block composites made of discarded and/or recycled materials. The aim is to make a material that is resistant to degradation by chemicals or climate, can withstand natural disasters, and endure through human-made conditions (such as urban overcrowding or pollution). The composites must be made of materials that are inexpensive and readily available so that they are viable alternative in shantytown communities. Students assess the results both chemically and physically and then iterate their designs with the materials that proved to be strongest.Engineering Connection

Materials engineers design and discover new solids to help solve problems. Building and iterating to solve a problem (like exploring the cement composites in this activity) are essential to the engineering design process. In this activity, students—given specific constraints—design a composite material that is cost-effective, chemically resistant, durable, and even aesthetically pleasing for shantytown residents. The composites are tested chemically and physically, and then redesigned based on results from testing. Engineers use creative problem solving to tackle a variety of issues, such as providing infrastructure expertise to communities in developing nations, who may then apply this engineering knowledge to tackle the economic and social problems of shantytowns.

Learning Objectives

After this activity, students should be able to:

- Describe how different foundational materials affect the chemical and physical properties of a finished composite.

- Apply the engineering design process to build a composite concrete block with an optimal mixture of materials based on cost, availability, material properties and aesthetic appeal.

- Analyze and present data on block construction and further iterations that come from the engineering design process.

Educational Standards

Each Teach Engineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each Teach Engineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in Teach Engineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-2. Design a solution to a complex real-world problem by breaking it down into smaller, more manageable problems that can be solved through engineering. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Design a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | Criteria may need to be broken down into simpler ones that can be approached systematically, and decisions about the priority of certain criteria over others (trade-offs) may be needed. Alignment agreement: | |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-ETS1-3. Evaluate a solution to a complex real-world problem based on prioritized criteria and trade-offs that account for a range of constraints, including cost, safety, reliability, and aesthetics, as well as possible social, cultural, and environmental impacts. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Evaluate a solution to a complex real-world problem, based on scientific knowledge, student-generated sources of evidence, prioritized criteria, and tradeoff considerations. Alignment agreement: | When evaluating solutions it is important to take into account a range of constraints including cost, safety, reliability and aesthetics and to consider social, cultural and environmental impacts. Alignment agreement: | New technologies can have deep impacts on society and the environment, including some that were not anticipated. Analysis of costs and benefits is a critical aspect of decisions about technology. Alignment agreement: |

| NGSS Performance Expectation | ||

|---|---|---|

|

HS-PS2-6. Communicate scientific and technical information about why the molecular-level structure is important in the functioning of designed materials. (Grades 9 - 12) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This activity focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Communicate scientific and technical information (e.g. about the process of development and the design and performance of a proposed process or system) in multiple formats (including orally, graphically, textually, and mathematically). Alignment agreement: | Attraction and repulsion between electric charges at the atomic scale explain the structure, properties, and transformations of matter, as well as the contact forces between material objects. Alignment agreement: | Investigating or designing new systems or structures requires a detailed examination of the properties of different materials, the structures of different components, and connections of components to reveal its function and/or solve a problem. Alignment agreement: |

Common Core State Standards - English

-

Follow precisely a complex multistep procedure when carrying out experiments, taking measurements, or performing technical tasks; analyze the specific results based on explanations in the text.

(Grades

11 -

12)

More Details

Do you agree with this alignment?

-

Integrate and evaluate multiple sources of information presented in diverse formats and media (e.g., quantitative data, video, multimedia) in order to address a question or solve a problem.

(Grades

11 -

12)

More Details

Do you agree with this alignment?

-

Synthesize information from a range of sources (e.g., texts, experiments, simulations) into a coherent understanding of a process, phenomenon, or concept, resolving conflicting information when possible.

(Grades

11 -

12)

More Details

Do you agree with this alignment?

Common Core State Standards - Math

-

Reason quantitatively and use units to solve problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Solve equations and inequalities in one variable

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Summarize, represent, and interpret data on two categorical and quantitative variables

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data on two quantitative variables on a scatter plot, and describe how the variables are related.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Students will develop abilities to assess the impact of products and systems.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of and be able to select and use manufacturing technologies.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the attributes of design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of engineering design.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop abilities to apply the design process.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the relationships among technologies and the connections between technology and other fields of study.

(Grades

K -

12)

More Details

Do you agree with this alignment?

-

Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

(Grades

K -

12)

More Details

Do you agree with this alignment?

State Standards

Ohio - Math

-

Summarize, represent, and interpret data on two categorical and quantitative variables.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Represent data on two quantitative variables on a scatter plot, and describe how the variables are related.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Reason quantitatively and use units to solve problems.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Solve equations and inequalities in one variable.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Ohio - Science

-

Structure and Properties of Matter

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Interactions of Matter

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Reactions of matter

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Implications for properties of substances

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Types of forces (gravity, friction, normal, tension)

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Formulate and revise explanations and models using logic and evidence (critical thinking)

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Recognize and analyze explanations and models

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Materials List

For the teacher’s introductory presentation:

- laptop/tablet, internet access, word processing access, presentation access (e.g., Google Slides, PowerPoint, Prezi)

Note: The following is for a class of 30 working in groups of three students each.

Each group needs:

- 3 pairs of gloves

- 3 Rubbermaid or Sterilite ice cube bins, such as at Walmart

- 3-4 paint sticks, such as a 10-pack at Home Depot (or for free from most stores that sell paint if you say it is for a school project)

- 1 small bucket (3 gallons or less) from hardware store or Amazon

- 3 dust masks, such as packs of 50 from Amazon

- Making Concrete Blocks Lab sheet

For the entire class to share:

For making concrete blocks

- recycled, reused or discarded items; have students bring from home (ideally, collect materials that fall under one of three categories: metals, ceramics, polymers, or composites)

- 10-12 pairs of scissors

- 1-2 hammers

- lab scale or lab balance

- (optional but highly recommended) plastic wrap and masking or painter's tape to protect the balances

- (optional but highly recommended) large tarps and painter's tape to protect the lab area; 6 x 8-foot blue, multipurpose, waterproof Grizzly Tarps work well, from Amazon.

- 2 bags of Sakrete: 94-lb Portland Cement Type I/II Commercial Grade Quickrete, available at hardware stores like Lowe's or Home Depot

- buckets for cement mixing

- cups for scooping out and weighing cement; such as 8 oz. Styrofoam cups

- 6-8 gallons of water (tap water is okay)

- (optional) 1 premade sample to serve as example

For chemical testing

- 3 pairs of goggles

- 1-12 medium test tubes, large test tubes, small beakers or small cups

- Materials for labeling test tubes and beakers

- up to 12 pipettes

- up to 12 small samples of the chosen substrate

- Chemical Testing Lab sheet, 1 per group

- up to 12 beakers/cups for putting classroom samples into

- 10 ml of the following samples:

- bleach

- vinegar

- oil

- dirty/polluted water

- dirty/polluted salt water

- dish soap

- laundry soap

- hydrochloric acid (HCl)

- sodium hydroxide (lye) (NaOH)

- acetone (CH3)2CO (paint thinner or nail polish remover)

- household drain cleaner

For physical testing

- small crane scale, available at Amazon

- gallon heavy-duty Ziploc bags for drop test

- block crushing machine (see image below); have students make this simple machine possibly with the assistance of an industrial arts or wood shop class; see build instructions on the Block Crusher Design Instructions

- (optional) a few extra bolts for the block crusher; for sizing, refer to the Block Crusher Design Instructions extra individual assignments for students to work on while testing is occurring; see the Extra Individual Assignments

- (optional) a premade sample concrete block to use as a control; follow the Making Concrete Blocks Lab to build the block

Reuse most of the items from the Making Concrete Blocks Lab, but may need additional items such as:

- additional recycled, reused or discarded items that students bring from home (ideally, have the materials fall under one of three categories: metals, ceramics, polymers, or composites)

- 1 pair of gloves per person

- 1 bag Sakrete: 94-lb Portland Cement Type I/II Commercial Grade Quickrete, available at hardware stores like Lowe's or Home Depot

- 3 gallons of water

Worksheets and Attachments

Visit [www.teachengineering.org/activities/view/uod-1921-shantytown-construction-redesign-composite-material-science] to print or download.Pre-Req Knowledge

An understanding of the basic properties of materials (both chemical and physical).

Knowledge of laboratory and lab safety best practices.

Intermediate skills in Microsoft® Excel® (to create graphs); Microsoft® PowerPoint®, Prezi, or Google Slides (to create presentations); Google Drive.

Introduction/Motivation

(Have the Shantytown Redesign PowerPoint Presentation ready.)

Note: The presentation provides many ways to introduce (and help students understand) the problem. Slide contents include a video, shantytown pictures from news websites, statement of he design challenge and a graphic of the engineering design process—which may be used separately or combined. See the Activity Scaling section for more ideas on introducing the topic as well as project management tools.

On October 4, 2016, Hurricane Matthew made landfall near southwestern Haiti—one of the most impoverished nations in the Western Hemisphere. Matthew, a late-season Category 5 hurricane, swept ashore with peak sustained winds of 150 mph (240 km/h) causing massive devastation, 546 fatalities, and $1.6 billion dollars in damage. Many communities in Haiti, which were still recovering from a catastrophic earthquake in 2010, were affected by Matthew, particularly those made up of shantytowns—poorly constructed homes often built with salvaged or low-quality materials.

Shantytowns exist for multiple reasons, many of which are related to a country’s political and socioeconomic climate. While engineers may not be able to creatively problem-solve those issues, they can help by empowering residents of shantytowns with alternative construction options: materials that are more durable but also accessible and not cost-prohibitive.

As a team of engineers, your challenge is: How can we improve the quality of building materials in shantytowns with readily accessible and repurposed materials? Guided by the steps of the engineering design process, you will create a cement-based composite to be used for wall or roof construction that is lightweight, durable, chemical resistant, weather resistant, and aesthetically pleasing. Your composite concrete block must be made of materials that are readily available to shantytown residents. Other guiding considerations for your constructions may include the material’s ability to meet the residents':

- physical needs (climate and health)

- social needs (sense of community)

- emotional needs (safety and security)

- environmental needs (sustainability)

Procedure

Background

Materials science engineers classify all materials into four categories: metals, polymers, ceramics, and composites. Metals are materials that, when freshly prepared, polished, or fractured, have a lustrous appearance, and conduct electricity and heat. They are typically malleable or ductile (can be drawn into wires). Polymers are carbon-based compounds with covalent bonds. They tend to be pliable and flexible when in the solid phase. They include rubber, plastic, elastic, wood, wax, and many fabrics. Ceramics generally contain very strong, rigid ionic bonds. They include substances like brick, bone, teeth, glass, cement, and ceramic. Though they can be strong, ceramics can also be fragile. Composites are a combination of materials of differing chemical and physical properties that, when combined, create a substance with properties that are different than the component parts. Materials scientists also deal with the chemical properties and physical properties of a substance.

Before the Activity

Note: Attempt to connect with a community partner in a shantytown, if at all possible, via a local non-governmental organization developmental organization, or even through social media channels. This helps students become invested in the activity. Another option is to put your results online so people engaged in similar work can benefit from your students’ research and testing.

- Divide the class into groups of three students each. These groups make up the teams for the project duration.

- Build the crusher as described in the Block Crusher Design Instructions. (Consider recruiting students or an industrial arts or wood shop class.)

- Build 1 sample concrete block to use as example, and to get a feel for how the blocks are constructed.

- Assign several students to serve as documentarians through social media, presentations, etc.

With the Students (timeline estimated for 45-50 minute class periods; your timing may vary)

- Introduction to STEM Learning, Shantytown Redesign Project (Day 1)

- Go over Introduction to STEM Education and Habits of Mind, Engineering Design Process, and Questions to Consider via the Shantytown Redesign PowerPoint Presentation. Example questions are provided in the presenter's notes.

- Go over the four types of materials from the background section. Consider posting the definitions of these materials (metals, polymers, ceramics, and composites) in the classroom or online so students may refer to the definitions, if needed.

- As a class, start the “Know/Need to Know Chart” in the presentation.

- Research Time (Day 2-3)

- Finish “Know/Need to Know Chart” (questions) if necessary.

- Have students watch NOVA: Making Stuff Stronger on NOVA PBS YouTube.

- Introduce the Making Concrete Blocks Lab.

- Direct students to plan and brainstorm what will be used as the composite materials for their concrete blocks. Instruct them to bring in materials these from home or choose from any of the materials available in class (see the Materials List).

- Lab Prep (Day 4)

- Organize all materials for building concrete blocks.

- Cover the lab area in preparation for the upcoming Making Concrete Blocks Lab (see Making Concrete Blocks Lab).

- Making Concrete Blocks Lab, Part 1 (Day 5)

- Facilitate students in conducting the Making Concrete Blocks Lab.

- Each student is responsible for making his/her own concrete block. Each person adds one type of material composite to his/her cement mix.

- Making Concrete Blocks Lab, Part 2 continued (Day 6)

- Continue facilitating students in conducting the Making Concrete Blocks Lab.

- Have students weigh and record both their material sample and cement.

- Direct students to prepare their cement mixture and found materials. The water must be added and mixed on the same day.

- After students mix their test pieces together, have them write their name on a piece of tape and attach it to the tub. Take the test pieces to a designated area in the classroom so they can dry over the next two days. Pouring the blocks on a Friday is a good way to ensure they set over the weekend.

- Chemical Testing Lab (Day 7-8)

- Have students finish the Making Concrete Blocks Lab calculations.

- Hand out the Chemical Testing Lab sheet.

- Have students prep for the Chemical Testing Lab by using samples of their composite material small enough to fit into a test tube or beaker. Students can either cut off a piece of the block, or use a leftover piece from the construction process.

- Label each sample.

- Have students perform the Chemical Testing Lab and lab questions.

- Chemical Test Discussion and Physical Testing (Day 9-10)

- As a class, have a large group discussion about the chemical test results.

- Introduce the Physical Testing Lab. (See the Physical Testing Lab sheet.)

- Have students crush their blocks as they work through the physical testing.

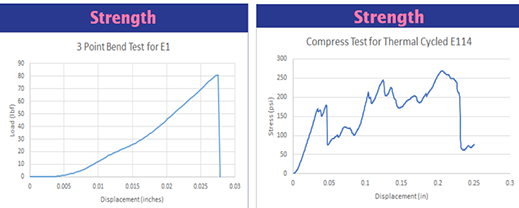

- Direct the teams to complete the lab questions, including making graphs in Excel or Google Sheets. See Figure 1 for examples of a “Load vs. Displacement” graph and a “Stress vs. Displacement” graph.

- Evaluation of Results and Redesign Iteration (Day 11)

- Discuss the chemical and physical test results or have students do a more formal evaluation using the Concrete Test Results Evaluation.

- Explain how engineers iterate designs, and that they will redesign their concrete based on test results. Give students time to work in groups to redesign, sketch, etc.

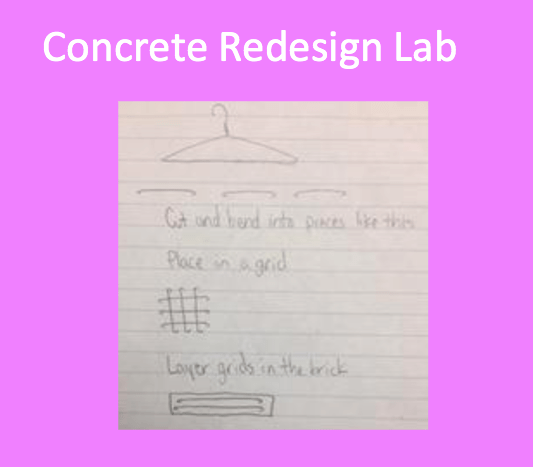

- Concrete Redesign Lab (Day 12-13)

- See the Concrete Redesign Lab and Making Concrete Blocks Lab sheet. Have each group iterate its previous design. You need a couple days for the blocks to harden, so students can make corrections to their Making Concrete Blocks Lab calculations; put composite materials information (how the material was orientated in the block, pictures, description of how the block behaved during the test, graphs) into the class presentation; or work on Extra Independent Assignments.

- Physical Testing of Redesign Blocks (Day 14)

- Repeat physical testing with redesigned blocks.

- Final Assessment and Finish Extra Individual Assignments (Days 15-16)

- Conduct final project assessments. See the Final Assessment Flyer and the Exit Interview. Other assessment options include having students use the classroom presentation to give presentations to different groups such as your community partner, your school administration, a parent group, colleagues, afterschool groups, etc.

Vocabulary/Definitions

cement: Substance often made with lime and clay that is used to bind sand and gravel, or aggregate together. It is mixed with water to form mortar or mixed with sand, gravel, and water to make concrete.

ceramic: An inorganic non-metallic solid made up of either metal or non-metal compounds that have been shaped and then hardened by heating to high temperatures.

chemical property: A quality of a material that can be established only by changing a substance’s chemical identity. Examples include if a material is flammable, prone to rust or oxidization, reacts with acids, etc. (See “physical property.”)

composite: Materials with significantly different chemical and physical properties that, when combined, create a substance with properties that are different than the component parts.

metal: A material that, when freshly prepared, polished, or fractured, has a lustrous appearance, and conducts both electricity and heat.

physical property: Density, hardness, color, or flexibility; something that can be determined without changing the identity of the substance. (See “chemical property.”)

polymer: A substance that has a molecular structure consisting chiefly or entirely of a large number of similar units bonded together; for example, many synthetic organic materials used as plastics and resins.

strength of material: Dealing with the behavior of solid objects subject to stress and strain; also known as mechanics of materials.

stress: A physical quantity that expresses the internal forces that neighboring particles of a continuous material exert on each other For example, one can model different types of stresses using clay: compressive strength (pushing down), tensile strength (pulling apart), shear strength (tearing in different directions), and bending strength.

Assessment

Pre-Activity Assessment

Discussion Questions: Ask students the following questions:

- What are the steps of the engineering design process? (Answer: Ask to identify the needs and constraints, research the problem, imagine possible solutions, plan by selecting a promising solution, create a prototype, test and evaluate the prototype, improve and redesign as needed.)

- What factors affect the quality of buildings in a shantytown? (Possible answers: social issues, economic issues, politics, jobs, etc.)

- Consider Probing Questions worksheet and “Know/Need to Know” chart in Shantytown Redesign PowerPoint Presentation.

Activity Embedded Assessment

Which materials make the best composite?

- Making Concrete Blocks Lab—calculating what percentage a composite is made of. (See Making Concrete Blocks Lab)

- Chemical Test Lab—evaluation of the chemical properties of each substrate. (See Chemical Test Lab)

- Physical Testing Lab and Concrete Redesign—graph; evaluation of durability, costs, etc., of redesigned blocks; use of engineering design process. (See Physical Testing Lab--Strength, Concrete Test Results Evaluation, Concrete Redesign Lab)

Post-Activity Assessment

Final Assessment:

- Group presentations, use of engineering design process, evaluating the three best blocks based on data (See Final Assessment Flyer)

Whose block is the best? Conduct group presentations on the best composites based on classroom data. Instruct students to:

- Identify the materials in your composite including ratios/percentages of each material.

- What is the difference between the physical and chemical properties of a give material? Explain.

- Explain the properties of your composite. Discuss your materials, why you chose them, and how they behaved.

- Draw and explain the engineering design process.

- Where are the points of failure on your stress-strain curve?

- Use your composite to explain the difference between strength and durability (toughness). How does this relate to engineering?

Safety Issues

- Making Concrete Blocks and Concrete Redesign Labs: Cement can irritate and dry out skin. Gloves and dust masks are required equipment.

- Chemical Testing Lab: Since the chemical testing portion of this activity requires handling a number of potentially harmful chemicals, please refer to your school’s lab safety policies to ensure all the necessary precautions and guidelines are in place.

- Physical Testing Lab: This testing involves crushing concrete blocks with the block crusher as well as at height. Closed-toes shoes, safety glasses, gloves, and dust masks are required as well as basic safety precautions when performing crush tests.

Troubleshooting Tips

- Use the provided Extra Independent Assignments to ensure all students are working at all times.

- Wait for the scales to stop moving while you are doing the physical testing.

Activity Extensions

Investigate the surface design of concrete materials. Combine the information from this activity with the artistic perspective to mutually work with an art class to see what artistic components can be added to create a better-looking finished concrete product for home building.

Activity Scaling

In an activity of this size and scale, classroom management issues are invariable challenges that occur over the course of several weeks. To help mitigate the effects of these issues on the teacher and students, review some of the supplemental research and assessment attachments. These documents include ideas for having students conduct internet research, perform self-evaluations, project planning and management, journaling, and other extension and enrichment activities that complement the engineering aspect of this activity. For more imformation, see Bell Ringer Ideas, Guidelines for Internet Research, Journal Activity, Mini Presentation Evaluation, Probing Questions, Project Planning Log, Sample Letter Template, Peer Group Evaluation, and Teacher Team Conference.

Additional Multimedia Support

- NGO Aid Map—Haiti Aid Map: https://www.one.org/stories/haiti-aid-map-visualizing-two-years-of-coordinated-response/

- Southern African NGO Network: http://www.ngopulse.org/node/23881

- Haiti: They Call It Canaan: https://pulitzercenter.org/reporting/haiti-they-call-it-canaan

- Problems and solutions: less developed countries: https://www.s-cool.co.uk/a-level/geography/urban-profiles/revise-it/problems-and-solutions-less-developed-countries

- Al-Jazeera: Death and destruction as Hurricane Matthew batters Haiti: https://www.youtube.com/watch?v=iYPAZ9FQRYo

- PBS NOVA Making Stuff Stronger Video: https://www.youtube.com/watch?v=aKgEV_5jsbw

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students combine paper strips to measure how much gravitational force the paper can withstand by adding masses to the combined paper strips until they tear. Students compare the strength of one paper strip versus the combination of two, three, four, and five strips. Students cut out paper strips and...

Over several days, students learn about composites, including carbon-fiber-reinforced polymers, and their applications in modern life. This prepares students to be able to put data from an associated statistical analysis activity into context as they conduct meticulous statistical analyses to evalua...

Students create beams using Laffy Taffy and water, and a choice of various reinforcements (pasta, rice, candies) and fabricating temperatures. Student groups compete for the highest strength beam and measure flexure strength with three-point bend tests and calculations.

References

Geetha, S., Madhavan, S. Light Weight Composite for Structural Wall Panels. 2015. ScienceDirect, 2(4-5), 2928-293. Accessed August 28, 2018. https://www.sciencedirect.com/science/article/pii/S2214785315005003

“Global Health Observatory (GHO) data; Urban health.” 2015. World Health Organization. Accessed August 28, 2018. http://www.who.int/gho/urban_health/en/

Sumrall, O. “Lightweight concrete composite blocks” June 22, 2001. Google Patents. Accessed August 31, 2018. https://patents.google.com/patent/US20060000172

“Select a Volunteer Project.” 2018. Community In Action. Accessed August 28, 2018. http://communityinaction.org/volunteer-project/

“The Effects and Economic Impact of Corrosion.” 2000. ASM International. Accessed August 28, 2018. http://www.asminternational.org/documents/10192/1849770/06691G_Chapter_1.pdf

“Tin Roof Installation Cost.” Fixr.com. Accessed August 28, 2018. http://www.fixr.com/costs/install-tin-roof

“Working with Concrete.” PCA: America’s Cement Manufacturers. Accessed August 28, 2018. http://www.cement.org/cement-concrete-basics/working-with-concrete/curing

Copyright

© 2018 by Regents of the University of Colorado; original © 2016 Central State University, University of Dayton, and Wright State UniversityContributors

Marjorie Langston; Nicholas Kaufman; Jenny Montgomery; Kerensa Hughes; Brett DoudicanSupporting Program

Collaborative RET Program, Central State University, University of Dayton, and Wright State UniversityAcknowledgements

This material is based upon work supported by the National Science Foundation under grant no. EEC 1405869—a collaborative Research Experience for Teachers Program titled, “Inspiring Next Generation High-Skilled Workforce in Advanced Manufacturing and Materials,” at the University of Dayton, Central State University and Wright State University in Ohio. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: July 2, 2025

User Comments & Tips