Quick Look

Grade Level: 10 (9-12)

Time Required: 30 minutes

Lesson Dependency: None

Subject Areas: Biology, Life Science, Science and Technology

Summary

Students learn about the role engineers and engineering play in repairing severe bone fractures. They acquire knowledge about the design and development of implant rods, pins, plates, screws and bone grafts. Students then can use the associated activity to practice their own bone repairing procedure. They learn about materials science, biocompatibility and minimally-invasive surgery.Engineering Connection

Biomedical engineers and materials science engineers create devices that doctors use to repair severe bone fractures. Biomedical engineers design devices that work well with the body, and can be implemented with relatively little pain for the patient and with relative ease by a doctor or surgeon. Materials science engineers create and design materials that are accepted by the body and have properties similar to bone and other human tissues.

Learning Objectives

After this lesson, students should be able to:

- Describe how engineers aid doctors in repairing severe bone fractures.

- Describe two factors that engineers must consider when designing devices to help heal fractured bones.

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

-

CCC.6.9-12.6.

Investigating or designing new systems or structures requires a detailed examination of the properties of different materials, the structures of different components, and connections of components to reveal its function and/or solve a problem.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

-

CCC.6.9-12.7.

The functions and properties of natural and designed objects and systems can be inferred from their overall structure, the way their components are shaped and used, and the molecular substructures of its various materials.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

-

CCC.8.9-12.13.

Modern civilization depends on major technological systems. Engineers continuously modify these technological systems by applying scientific knowledge and engineering design practices to increase benefits while decreasing costs and risks.

(Grades 9 - 12)

More Details

Do you agree with this alignment?

International Technology and Engineering Educators Association - Technology

-

Medical technologies include prevention and rehabilitation, vaccines and pharmaceuticals, medical and surgical procedures, genetic engineering, and the systems within which health is protected and maintained.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

-

Connect technological progress to the advancement of other areas of knowledge and vice versa.

(Grades

9 -

12)

More Details

Do you agree with this alignment?

State Standards

Colorado - Science

-

Discuss how two or more body systems interact to promote health for the whole organism

(Grades

9 -

12)

More Details

Do you agree with this alignment?

Worksheets and Attachments

Visit [www.teachengineering.org/lessons/view/cub_biomed_lesson10] to print or download.Pre-Req Knowledge

A basic understanding of bones, how they work and what they are made of. See the Our Amazing Skeleton lesson.

Introduction/Motivation

(Have ready to show to the class the attached Bone Repair and Biomedical Engineering PowerPoint presentation, which contains information, explanations, drawings, photographs and examples of the subject matter covered in the Lesson Background & Concepts for Teachers section. Follow-up with a quiz, as described in the Assessment section.)

How many of you have had a broken bone? Or, know someone who has? What did the doctor do to fix it? (Expect "Put a cast on it" to be a common answer.) Do any of you know of other steps doctors take to fix more serious breaks? (Take suggestions from students.) That's correct, doctors use rods, pins, plates and screws to help repair broken bones. Do you think doctors design, create and use pins, plates and rods by themselves? Biomechanical engineers and materials science engineers help doctors develop and design bone-fixing devices. These engineers play important roles in making sure the materials will be accepted by the body and not lead to other complications. They design special surgical stainless steel, titanium alloys and polymers especially for medical implants. They also make sure that the devices can be inserted in a way that supports the body in repairing the bone, and not weaken it.

Engineers must consider many things when designing devices to repair broken bones. Some important things to consider are:

- Is it strong?

- Is it minimally invasive?

- Is it biocompatible?

- Is it inexpensive?

- Is it easy to implement?

Engineers want devices to be strong enough to support the body, match the properties of bone well, and not be rejected by the body. Doctors desire devices that are easy to implant, inexpensive, and minimally invasive for the patient. All of these factors have been considered and have influenced current bone repair devices and techniques. Next, let's learn more about how engineers aid doctors in repairing serious bone fractures.

(Show the class the attached Bone Repair and Biomedical Engineering PowerPoint presentation, and follow-up with a quiz as described in the Assessment section. Then conduct the Repairing Broken Bones activity to have students design their own prototype to fix broken bones)

Lesson Background and Concepts for Teachers

Typical Breaks

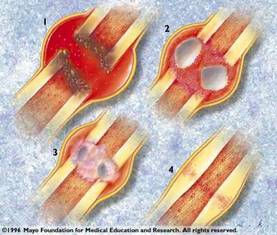

When a bone breaks it immediately begins to heal itself. When minor fractures occur, doctors cast the broken region so it will not move while healing. Figure 1 illustrates the steps of this healing process. Problems occur, however, when bones are not able to heal correctly on their own. In these cases, doctors and engineers are needed.

Bone Repair

(See the attached Bone Repair and Biomedical Engineering PowerPoint presentation.) When severe fractures occur, doctors and engineers help the body repair broken bones for certain reasons:

- To restore function and position

- Likely not to heal correctly

- A high risk of infection

- A very long healing time

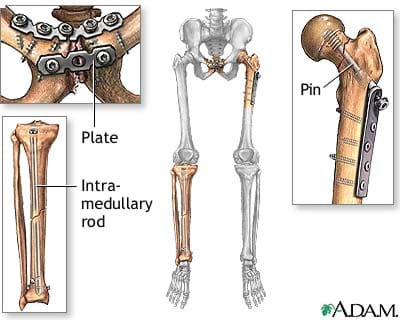

The two categories of bone repair are internal and external fixation. Internal fixation is temporary or permanent fixtures directly attached to the bone under the skin, for alignment and support. Internal fixation includes pins, rods, plates, screws, wires and bone grafting.

External fixation is temporary repair supports outside of the skin that stabilizes and aligns bone while the body heals. External fixation includes screws in the bone to hold it in place, and metal braces or casts; these can be externally adjusted.

Internal fixation is recognized for providing increased patient mobility and quicker healing time.

Materials Engineering

Materials science engineers play important roles in designing devices and technologies to help heal fractured bones; they continually seek and concoct materials that closely match bone properties and are biocompatible. This is challenging! Bone is incredibly strong while also being fairly flexible, while most strong materials are brittle and unable to flex like bone.

Commonly used implant material for orthopedic devices include surgical stainless steel, titanium alloys and polymers. Stainless steels are made from nickel, chrome and molybdenum, combined into endless combinations for characteristics that are desired for different applications (strength, flexibility, biocompatibility, etc.). While the "surgical" versions are designed to be easy to sterilize, strong, and corrosion-resistant, sometimes the human immune system reacts to the nickel component. Titanium is a reactive metal and its surface quickly oxidizes upon exposure to air, which provides an excellent surface on which bone grows and strongly adheres. Advances are being made in the uses of polymers that are designed to degrade in the body. Sometimes a fractured bone that is supported by a steel plate can be re-fractured, damaged, or opened to risk of infection upon removal of the device. But, the same device made of a polymer can be engineered to degrade at a rate that slowly transfers load to the healing bone and does not require another surgical procedure to remove.

Associated Activities

- Repairing Broken Bones - Students investigate the processes that biomedical engineers use to aid doctors in repairing severely broken bones by designing, creating and testing their own prototype devices to repair broken turkey bones.

Lesson Closure

What are some of the current devices and techniques designed by engineers to help doctors repair severely broken bones? (Answer: Pins, rods, plates, screws, wires, bone grafting, metal braces, casts, slings.) Which of these are used temporarily? Which might be used permanently? What's a difference between internal and external fixation? (Answer: Repair work that is attached directly to the bone [under the skin] is internal fixation; repair supports outside of the skin are external fixation.)

While the current technology for bone repair has greatly increased the number of bones that are successfully healed each year, much improvement can still be made. Young engineers (like you!) still have work to do. As you saw in the presentation, some surgeries are intense and invasive, and can result in patients being in hospital for long periods of time.

What things might engineers take into consideration when designing devices to help heal fractured bones? (Answer: Strength, minimally invasive, biocompatibility, expense, ease of implementation.) Engineers play important roles in making sure the materials are accepted by the body, and that the devices can be inserted safely into the body. A commonly-used material, titanium alloy, is as strong but not as flexible as bone. Do you think engineers can still improve the implementation and materials used in bone repair?

Vocabulary/Definitions

biocompatibility: A characteristic of some materials that when they are inserted into the body do not produce a significant rejection or immune response.

biomedical engineer: A person who blends traditional engineering techniques with the biological sciences and medicine to improve the quality of human health and life. Biomedical engineers design medical devices and implants, artificial body parts, surgical and diagnostic tools, and medical treatment methods.

bone graft: Bone taken from a patient during surgery or a bone substitute that is used to take the place of removed bone or to fill a bony defect.

external fixation: The process of installing temporary repair supports outside of the skin to stabilize and align bone while the body heals. Examples: screws in bone, metal braces, casts, slings.

fracture: An injury to a bone in which the tissue of the bone is broken.

internal fixation: The process of fastening together pieces of bone in a fixed position for alignment and support, using pins, rods, plates, screws, wires, grafting, and other devices, all under the skin. Can be temporary or permanent fixtures.

intramedullary rod: A medical device inserted into the bone marrow canal in the center of the long bones, such as femur or tibia.

materials science engineer: A person who studies the characteristics (composition, structure, behavior) and processing of materials for purposes of their use in science, engineering and technology. This includes the study and design of metallic, ceramic, polymeric and composite materials. Also called materials engineer.

orthopedist: A bone doctor.

Assessment

Pre-Lesson Assessment

Discussion Questions: Solicit, integrate and summarize student responses. Have students discuss the following questions together in small groups.

- Do you know anyone who has a rod, pin or plate in their body?

- Why do you think people need to have these devices put into their body?

- How do these things help people?

- What types of things do you think are considered in the making of rods, pins, plates and screws that are inserted into the body?

- Who do you think designs these types of devices?

Post-Introduction Assessment

Quiz: After completion of the Bone Repair and Biomedical Engineering PowerPoint presentation in the Introduction/Motivation portion of the lesson, have students complete the attached Bones Quiz.

Lesson Summary Assessment

Device Design & Presentation: Have students imagine they are biomedical and materials science engineers. Challenge groups of 3-4 students to design on paper their own devices to repair fractured tibiae (shinbones). Then have the teams present their designs to the class. Ask the groups to consider the following in their design:

- From what material is your device made?

- How does it support the body?

- Is it easily implanted?

- Would it be inexpensive?

- Do you think the body would accept it? (Is it biocompatible?)

Additional Multimedia Support

Refer to an excellent four-part bone fracture repair series that includes drawings and summary explanation of the devices and surgical procedures involved in fracture repair. See the MedlinePlus Medical Encyclopedia website at http://www.nlm.nih.gov/medlineplus/ency/presentations/100077_4.htm

Subscribe

Get the inside scoop on all things Teach Engineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn how forces affect the human skeletal system through fractures and why certain bones are more likely to break than others depending on their design and use in the body. They learn how engineers and doctors collaborate to design effective treatments with consideration for the location, ...

Students learn about how biomedical engineers aid doctors in repairing severely broken bones. They learn about using pins, plates, rods and screws to repair fractures. They do this by using the engineering design process to design, create and test their own prototype devices to repair broken turkey ...

Students learn about the strength of bones and methods of helping to mend fractured bones. Working as biomedical engineers, student teams design their own splint or cast to help repair a fractured bone, learning about the strength of materials used.

Students are introduced to how engineering closely relates to the field of biomechanics and how the muscular system produces human movement. They learn the importance of the muscular system in our daily lives, why it is important to be able to repair muscular injuries and how engineering helps us by...

References

Bone fracture repair-series, Procedure. Last updated September 21, 2009. MedlinePlus Medical Encyclopedia, US National Library of Medicine, National Institutes of Health. Accessed October 29, 2009. http://www.nlm.nih.gov/medlineplus/ency/presentations/100077_3.htm

Internal Fixation for Fractures (wires, pins, plates, nails or rods, screws, etc.) Updated August 2007. Your Orthopaedic Connection, American Academy of Orthopaedic Surgeons. Accessed October 30, 2009. http://orthoinfo.aaos.org/topic.cfm?topic=A00196&return_link=0

Martini, Frederic H. Fundamentals of Anatomy & Physiology: Seventh Edition. San Francisco, CA: Pearson Education, Inc., 2006.

Middleton, John C. and Arthur J. Tipton. Synthetic Biodegradable Polymers as Medical Devices. Originally published March 1998. Medical Plastics and Biomaterials Magazine, Medical Device Link. http://www.devicelink.com/mpb/archive/98/03/002.html

Surgical Stainless Steel. Updated October 23, 2009. Wikipedia, The Free Encyclopedia. Accessed October 30, 2009. http://en.wikipedia.org/w/index.php?title=Surgical_stainless_steel&oldid=321664314

Copyright

© 2008 by Regents of the University of ColoradoContributors

Todd Curtis; Malinda Schaefer Zarske; Janet Yowell; Denise W. CarlsonSupporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado BoulderAcknowledgements

The contents of this digital library curriculum were developed under grants from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education and National Science Foundation (GK-12 grant no. 0338326). However, these contents do not necessarily represent the policies of the Department of Education or National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: May 14, 2022

User Comments & Tips